Introduction:

Careful planning and consideration of various factors are essential when making the significant decision to invest in a steel coil service center.

Among the most crucial factors to keep in mind is the packaging solution you choose, as it directly affects the efficiency, cost, and overall quality of your final product.

This article is designed to offer valuable insights into the comprehensive packaging solutions that you need to know before committing to an investment in a steel coil service center.

We’ll concentrate on highlighting the significance of long-term planning and the essential elements you must consider for Industry 4.0.

PART ONE: Key Elements to Consider for Industry 4.0

1.Datamation:

Implementing an ERP (Enterprise Resource Planning) system that tracks data from production to packaging and logistics is vital for seamless operation.

By utilizing this system, you’ll have the ability to oversee the entire process, identify any obstacles, and use data to make informed decisions that enhance efficiency.

Moreover, an ERP system can simplify inventory management, minimize the occurrence of human error during production, and promote seamless communication among various departments. Additionally,

ERP systems offer valuable customer insights, which can assist you in refining your product offerings and maintaining a competitive edge.

2. Automation:

Investing in an automatic machine for unmanned packaging is essential for a modern steel coil service center.

Despite the substantial upfront cost, the long-term advantages of reduced labor expenses, heightened efficiency, and superior product quality are substantial.

If you have concerns about budgetary restrictions, it’s recommended that the packaging solution you select is equipped with the potential for future upgrades to an automatic system.

3.Scalability:

As your steel coil service center grows, it is crucial to have a packaging solution that can scale with your needs.

This means choosing equipment and systems that are modular and can be easily expanded or upgraded as your production requirements increase.

This will help you avoid costly overhauls of your packaging line and ensure that you can adapt quickly to changes in market demand.

PART TWO: Comprehensive Automated Packaging Line Solutions

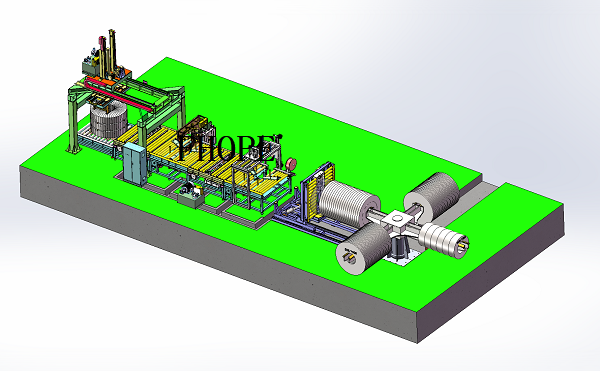

1. Coil Car:

A coil car transfers the slitting coil from the rewinding machine to the packing line automatically.

This equipment increases efficiency by reducing the need for manual labor and minimizing potential damage to the coils during transportation.

Coil cars are available in various capacities and configurations, allowing you to choose the optimal solution for your specific needs.

2. Automatic Wrapping:

Automated wrapping machines ensure consistent and secure packaging of steel coils.

This process not only enhances the appearance of the finished product but also protects the coils from environmental factors, such as moisture and corrosion, during storage and transportation.

Some automatic wrapping machines also offer customizable wrapping patterns and materials, allowing you to tailor the packaging to your specific requirements.

3. Automatic Strapping:

Automated strapping machines fasten steel coils securely, reducing the risk of damage during handling and transportation.

This process also increases efficiency by eliminating the need for manual strapping.

Modern strapping machines can handle various strap materials, widths, and tension levels, ensuring that your steel coils are secured according to industry standards.

4. Automatic Stacking:

Stacking steel coils manually can be time-consuming and labor-intensive.

Automatic stacking machines simplify this process, saving time and reducing the risk of workplace injuries.

These machines can be customized to handle different coil sizes and weights, ensuring that your finished products are stacked safely and efficiently.

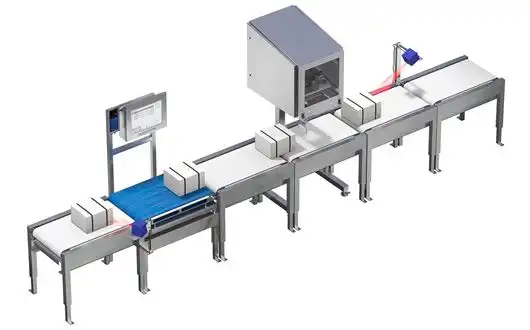

5. Automatic Labeling and Weighing:

Automated labeling and weighing systems ensure accurate and consistent information is provided on each steel coil.

This process reduces the risk of errors in product identification and helps streamline inventory management.

Advanced labeling systems can also generate barcodes or QR codes for easy tracking and identification throughout the supply chain.

6. Automatic Dispatching to the Warehouse:

Automated dispatching systems transport finished steel coils from the packing line to the warehouse, reducing manual labor and increasing efficiency in the logistics process.

These systems can be integrated with your ERP or warehouse management system, providing real-time updates on inventory levels and ensuring that your products are stored and dispatched efficiently.

![x8ciztpg]hx4u]$o`zll4ip](https://www.fhopepack.com/blog/wp-content/uploads/2023/07/X8CIZTPGHX4UOZLL4IP-300x296.jpg)