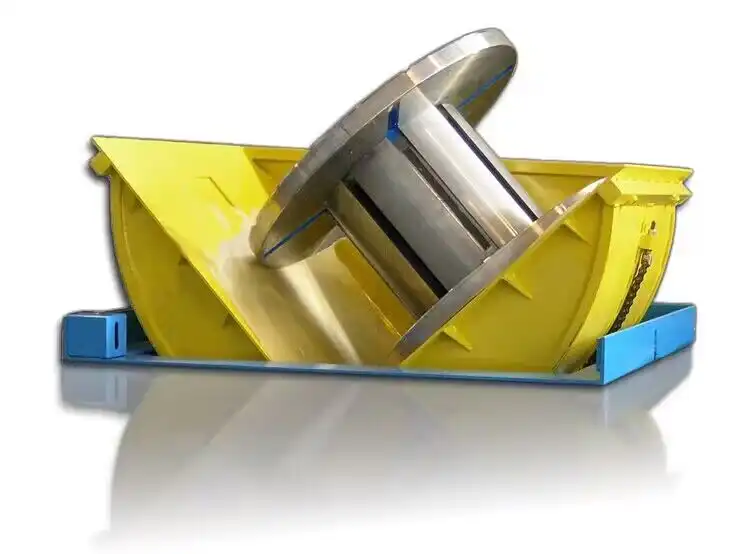

From my first encounter with coil tilter, I’ve been captivated by the engineering brilliance behind them. These machines, which transform the handling of heavy materials, serve as a cornerstone in industries ranging from steel manufacturing to cable production. Among the many manufacturers globally, Fhope Packaging Machinery Co., Ltd. stands out as an exemplar of innovation and customer satisfaction. Let me walk you through why this company has earned its reputation as the best coil tilter manufacturer in the world.

Their coil tilters are more than just machines—they represent precision, safety, and reliability. With user-friendly features like position locking, durable motor gear drives, and advanced safety measures, these tilters provide a seamless operation that meets the rigorous demands of modern industries. What truly sets Fhope apart is their commitment to tailoring each machine to customer-specific needs, ensuring optimal performance and efficiency in every use case.

In the following sections, I’ll detail how Fhope’s engineering, customization options, and customer support elevate their offerings above competitors. Whether you’re considering their hydraulic tilters or exploring their electric upenders, you’ll see why they lead the pack in industrial solutions.

1. Why Choose Fhope for Coil Tilters?

1.1 Tailored Solutions for Industry Needs

When selecting a coil tilter manufacturer, it’s crucial to consider how well the product aligns with your specific industry demands. Fhope excels by offering a range of tilters capable of handling diverse materials like steel coils, paper rolls, and plastic films. Their equipment accommodates a variety of dimensions, weights, and operational speeds, ensuring versatility. For example, their FPCT-20 model handles up to 20 tons and rotates with precision in just 60-90 seconds, making it ideal for high-paced industrial settings.

1.2 A Closer Look at Features: Safety and Precision

Fhope prioritizes safety with advanced design features such as emergency stops, automatic position fixing during power outages, and shielding for moving parts. Here’s a snapshot of their flagship model’s specifications:

| Parameter | Value |

|---|---|

| Max Weight Capacity | 20 Tons |

| Rotation Speed | 60-90 seconds |

| Power Consumption | 4.5 kW |

| Safety Features | Position locking, displacement restrictors |

These features ensure not only efficiency but also worker safety, which is vital in heavy industries.

1.3 The Role of Automation in Enhancing Usability

One of the standout qualities of Fhope’s coil upender equipment is its compatibility with automated systems. Whether through manual control panels or remote operations, their tilters integrate seamlessly with existing workflows. This ensures minimal downtime and higher productivity rates.

1.4 Durable Construction for Long-Term Use

Each Fhope tilter is designed with durable materials and components. The machines boast features like worm speed reducers and oblique gear mechanisms, which enhance both stability and operational longevity. Additionally, their electric panels, often sourced from trusted brands like Schneider, guarantee reliability.

| Component | Brand Used |

|---|---|

| Motor | YK/GPG/JIEMAI |

| Electric Panels | Schneider |

By choosing robust, high-quality materials, Fhope ensures their products withstand the test of time in demanding environments.

1.5 Fact or Myth: Are Fhope’s Machines Truly Maintenance-Free?

- Fact: The machines require minimal maintenance and can be operated by non-skilled workers. Features like flat working tables and adjustable plate-holding devices simplify regular use and upkeep.

- Myth: No machine is completely maintenance-free, but Fhope’s engineering significantly reduces wear and tear, making upkeep cost-effective.

2. What Makes Their Coil Tilters Unparalleled in Design?

2.1 Innovative Engineering for Versatility

Fhope’s design philosophy focuses on creating machines that adapt to various operational needs. Whether it’s rotating steel coils or managing delicate plastic rolls, their tilters are built with precision and flexibility. A perfect example is the FPCT-HT01 hydraulic tilter, which allows single-way turnover with adjustable speeds ranging from 15 to 30 seconds. The machine’s ability to stop at any angle adds another layer of control, ensuring precision even in high-stakes operations.

| Feature | Specification |

|---|---|

| Maximum Load Capacity | 1.5 Tons |

| Table Dimensions | 1600 x 1300 mm |

| Turnover Perspective | 90 Degrees |

| Speed Control | Adjustable via hydraulic valve |

2.2 Robust Materials for Longevity

Durability is a cornerstone of Fhope’s designs. From their motor drives to electrical panels, each component is sourced from trusted brands like Schneider and NOK. For instance, the sealing elements are crafted for maximum wear resistance, ensuring extended usage with minimal replacements.

2.3 Balancing Automation and Manual Control

Another hallmark of Fhope’s tilters is their ability to function seamlessly in both automated and manual workflows. Machines are equipped with remote control options and foot-switch controls, giving operators flexibility without compromising efficiency.

2.4 Dive Deeper into Patented Features

Fhope’s machines are designed with patented safety and operational features, such as their position-locking technology. This ensures the machine remains stable during sudden power outages. These elements make Fhope’s equipment a leader in industrial safety.

| Patented Feature | Benefit |

|---|---|

| Position Locking | Prevents unwanted movement |

| Emergency Stop | Immediate response in critical moments |

| Safety Guards | Protects operators from moving parts |

2.5 Fact or Myth: Are Fhope’s Machines Ideal for Irregular Floors?

- Fact: Machines come with micrometric setting devices, allowing adjustment for uneven surfaces.

- Myth: These devices are complicated to operate. In reality, they are straightforward, enabling operators to stabilize machines with minimal training.

3. How Does Fhope Address Industry Challenges with Customization?

3.1 Adapting to Unique Material Requirements

Fhope’s customization options allow their tilters to meet specific operational challenges. For example, the FPCT-20 coil tilter can handle oversized steel coils up to 80 inches in diameter and 72 inches in width. This adaptability is particularly beneficial in industries with unique material requirements, such as cable manufacturing.

| Material Handled | Customizable Specifications |

|---|---|

| Steel Coils | Diameter, width adjustments |

| Plastic Rolls | Speed and angle settings |

| Paper Rolls | Load capacity variations |

3.2 Flexible Manufacturing for Client-Specific Needs

What sets Fhope apart is their commitment to creating client-specific solutions. Their engineers work closely with customers to design machines that address individual pain points, from handling dimensions to operating speeds. A notable example is their ability to integrate specialized features like vibration-free motion.

3.3 Dive Deeper into Their Modular Designs

Fhope’s modular designs ensure seamless upgrades and easy maintenance. Customers can add components such as automated conveyors or advanced control panels without requiring a complete overhaul.

| Modular Component | Functionality Added |

|---|---|

| Conveyor Integration | Streamlined material handling |

| Advanced Control Panels | Enhanced automation |

3.4 Fact or Myth: Do Customizations Increase Delivery Times?

- Fact: Customizations can extend delivery times slightly but ensure a better return on investment in the long run.

- Myth: Customizations drastically inflate costs. In reality, Fhope balances affordability with high-quality engineering, making their solutions cost-effective.

4. What Are the Operational Benefits of Fhope’s Coil Tilters?

4.1 Increased Efficiency with Reduced Downtime

Fhope’s tilters are engineered to minimize operational delays. Features like soft start and stop mechanisms prevent abrupt movements, reducing the risk of damage to materials and ensuring smooth transitions.

4.2 Enhanced Safety and Compliance

Their machines meet international safety standards, including CE certification. Safety measures such as displacement restrictors and emergency alarms make them compliant with industry regulations, ensuring secure operations.

| Safety Feature | Compliance Benefit |

|---|---|

| Emergency Alarms | Reduces risk of accidents |

| CE Certification | Meets international standards |

4.3 Dive Deeper into Cost Savings

By investing in Fhope’s equipment, businesses can significantly lower operational costs. Their machines require minimal maintenance and reduce manual labor, contributing to long-term savings.

| Cost-Saving Factor | Average Reduction |

|---|---|

| Maintenance Costs | Up to 30% |

| Labor Costs | Up to 40% |

4.4 Fact or Myth: Can Fhope’s Machines Lower Energy Consumption?

- Fact: Machines like the FPCT-20 consume as little as 4.5 kW, making them energy-efficient.

- Myth: Low energy consumption compromises performance. In truth, Fhope balances efficiency with high operational output.

5. What Do Customers Say About Fhope’s Service and Support?

5.1 Customer Feedback: A Testament to Excellence

Fhope’s reputation in the industry is bolstered by glowing customer testimonials. Clients frequently commend their proactive service, from the initial consultation to post-installation support. One customer shared how their FPCT-20 coil tilter reduced operational inefficiencies by 40%, citing the machine’s reliability as a game-changer for their production line.

5.2 Comprehensive Warranty and Return Policies

Fhope offers a robust one-year warranty, covering unlimited cycles, and a 30-day refund or repair guarantee. This policy reflects their confidence in the durability of their products and their commitment to customer satisfaction.

| Service Feature | Customer Benefit |

|---|---|

| One-Year Warranty | Peace of mind |

| 30-Day Refund Guarantee | Risk-free investment |

| On-Site Support | Immediate troubleshooting |

5.3 Dive Deeper into Training and Installation

Fhope ensures that customers maximize the potential of their machines through comprehensive training programs. Installation is supervised by skilled technicians, who provide step-by-step guidance and ensure seamless integration into the existing workflow.

| Training Benefit | Impact |

|---|---|

| Hands-On Training | Reduces operator errors |

| Detailed Documentation | Simplifies troubleshooting |

5.4 Fact or Myth: Does Fhope Provide Support Beyond the Warranty Period?

- Fact: Fhope extends support services beyond the warranty, offering affordable maintenance plans to ensure long-term performance.

- Myth: Post-warranty support is limited. Customers often praise their responsiveness even years after purchase.

Conclusion: Why Fhope Leads the Market

When it comes to coil tilters, Fhope Packaging Machinery Co., Ltd. delivers unparalleled quality, innovation, and customer care. From their commitment to customization to their robust safety standards, Fhope sets the gold standard for manufacturers globally. Their machines don’t just meet industrial demands—they redefine them, providing solutions that are efficient, reliable, and tailored to future growth.

Whether you’re looking to optimize material handling or enhance operational safety, Fhope is the manufacturer to trust. With a proven track record and unwavering dedication to their clients, they truly deserve their title as the best coil tilter manufacturer in the world.