automatic steel pipe in-feeding machine and bagging machine.

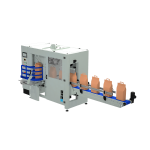

Pipe in-feeding machine:

Holds multiple racks of steel pipes of the same size

Feeds the pipes into the bagging machine at a controlled rate

Uses rollers, chain conveyors or pneumatic pushers to advance the pipes

Has a buffer section to compensate for fluctuations in bagging machine speed

Positioned above the bagging machine for gravity feeding of pipes

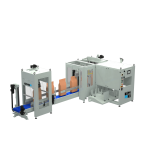

Bagging machine:

Contains a bagging hopper where open bags are loaded

Has a pipe inserting mechanism that indexes each bag and guides a pipe into it

Applies a tie wrap, seal or clip to close the bag around the pipe after insertion

Transfers full bags to a discharge conveyor

Control panel to set production speed and other parameters

Functions:

Empty bags are loaded into the bagging hopper

The in-feeding machine advances steel pipes onto guide rails above the bagging machine

A bag is indexed up from the hopper and opened

The pipe inserting mechanism guides a pipe from the feed into the open bag

The bag is closed around the pipe using a tie wrap, heat seal or clip

The full bag is discharged onto the conveyor

The process repeats continuously

Benefits:

Higher throughput by automating manual bagging

More consistent packing due to precision pipe insertion and bag closing

Less waste from tearing bags since they are automatically indexed and opened

Easy to integrate into existing automation lines

So in summary, an automatic pipe in-feeding machine works with a bagging machine to rapidly and precisely insert steel pipes into bags, closing them in an organized fashion to improve packing consistency and throughput.