Steel Stud & Track Roll Forming Machines: Enhancing Light Gauge Steel Framing Production

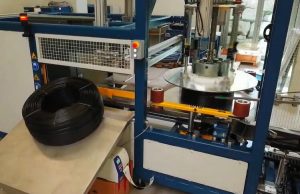

The construction industry increasingly relies on light gauge steel framing (LGSF) for its strength, durability, and efficiency. Central to this method are steel studs and tracks, precisely formed components that create the skeleton for walls, floors, and roofs. Steel Stud & Track Roll Forming Machines are the engineered systems designed specifically for the high-speed, automated production of these essential structural elements.

These sophisticated machines transform coils of galvanized or mild steel into C-shaped studs and U-shaped tracks through a continuous roll forming process. This involves passing the flat metal strip through a series of precisely contoured rollers, each incrementally shaping the steel until the final profile is achieved. The process ensures high dimensional accuracy and consistency, critical for structural integrity in modern building projects.

How Steel Stud & Track Roll Forming Machines Operate

The production of steel studs and tracks typically follows these automated steps:

- Decoiling: A coil of flat steel sheet is mounted onto a decoiler, which feeds the material into the machine.

- Feeding & Leveling: Guide rollers ensure the strip enters the forming section straight. Sometimes a leveler unit is included to remove any coil set.

- Roll Forming: The core process where the steel strip passes through multiple stations of driven rollers. Each station gradually bends the metal, forming the specific C (stud) or U (track) profile. The precision of these rollers dictates the final product's quality and dimensions.

- Punching (Optional): Some machines incorporate punching stations to create holes for wiring, plumbing, or specific connection points, often controlled by the PLC system.

- Cutting: Once the desired length is formed, an automated cutting system (often hydraulic or servo-driven) shears the profile cleanly. This can be a 'stop-to-cut' system or a 'flying shear' that cuts while the profile is still moving for higher speeds.

- Output & Stacking: The finished studs or tracks exit onto a run-out table, sometimes equipped with automated stacking systems for efficient handling and bundling.

- Control System: A Programmable Logic Controller (PLC) manages the entire operation, controlling line speed, cutting lengths, punching patterns (if applicable), and providing diagnostics. Operators typically interact via a touchscreen interface (HMI).

Key Components and Features

Understanding the components helps in appreciating the machine's capabilities:

- Decoiler: Holds and unwinds the steel coil. Can be manual or hydraulic, with varying weight capacities.

- Roll Forming Stands/Rollers: The heart of the machine. Rollers are typically crafted from hardened tool steel (like Cr12MoV) and chrome-plated for durability and corrosion resistance. The number of forming stations depends on the complexity of the profile and material thickness.

- Drive System: Powers the rollers, usually via electric motors with gear or chain transmission. Variable speed drives allow adjusting production rates.

- Cutting Mechanism: Hydraulic shears are common for their power, while servo-driven flying shears offer higher speed and precision without stopping the line.

- PLC Control System: Brands like Siemens, Mitsubishi, or Delta are often used, offering robust control over production parameters and batch management.

- Frame: A heavy-duty, stress-relieved frame ensures stability and alignment of the forming stations during operation.

Technical Specifications Overview

Please note: The parameters below represent typical ranges. Exact specifications vary by machine model and manufacturer. For precise details matching a specific machine, direct consultation is necessary.

- Machine Type: Steel Stud & Track Roll Forming Machine (producing C and U profiles)

- Material Compatibility: Galvanized Steel (G40-G90), Cold Rolled Steel

- Material Thickness Range: Typically 0.5mm to 1.5mm (Varies by machine design)

- Coil Width: Dependent on profile size, often up to 300mm or more.

- Profile Dimensions: Adjustable or fixed tooling for standard stud/track sizes (e.g., web width, flange height, lip return). Common sizes dictated by regional building standards.

- Production Speed: Highly variable, from 15-25 meters per minute up to 60+ m/min for high-speed lines.

- Cutting Length Tolerance: Typically +/- 1mm to 2mm.

- Control System: PLC with HMI touchscreen interface.

- Power Requirements: Standard industrial voltages (e.g., 380V/3Ph/50Hz or 480V/3Ph/60Hz), dependent on motor sizes.

- Safety Features: Emergency stops, safety guarding around moving parts.

Benefits of Automated Roll Forming for Studs and Tracks

Utilizing dedicated roll forming machines offers significant advantages over manual methods or purchasing pre-cut lengths:

- High Production Speed: Continuous operation enables rapid output, ideal for large projects or manufacturing environments.

- Consistent Accuracy: Automated forming ensures every stud and track meets precise dimensional tolerances, crucial for quality construction.

- Reduced Labor Costs: Automation minimizes manual handling and fabrication steps.

- Material Efficiency: Optimized cutting programs and continuous processing minimize scrap compared to manual cutting.

- Flexibility: Many machines allow quick changeovers between different profile sizes or feature adjustable tooling.

- Scalability: Meets the high-volume demands of commercial construction and prefabricated building manufacturers.

Common Applications in Construction

Steel stud and track roll forming machines are indispensable in various construction sectors:

- Commercial and Residential Framing: These machines produce the backbone for interior partition walls, exterior curtain walls, floor joists, and roof trusses in buildings of all sizes. The speed and precision facilitate faster project completion times.

- Modular and Prefabricated Construction: Manufacturers of modular homes, portable buildings, or prefabricated panels rely heavily on these machines for consistent, high-volume production of framing components. Automation ensures components fit perfectly during assembly.

- Renovation and Retrofitting: The ability to produce custom lengths on-demand is advantageous in renovation projects where non-standard dimensions are often required. This minimizes waste and allows for tailored solutions.

- Drywall Installation: As the primary components for drywall framing systems, accurately formed studs and tracks ensure smooth, plumb walls and ceilings.

Selecting the Right Steel Stud & Track Roll Forming Machine

Choosing the appropriate machine requires considering several factors:

- Production Volume: Match the machine's speed and automation level to your output requirements.

- Profile Requirements: Determine the range of stud and track sizes (web, flange, lip), and material thicknesses you need to produce.

- Material Type: Ensure the machine is designed for the specific steel grades (e.g., yield strength) you intend to use.

- Changeover Time: If producing multiple profiles, consider machines designed for quick tooling changes or adjustable tooling.

- Level of Automation: Decide between basic machines and fully integrated lines with automated punching, stacking, and bundling.

- Budget and ROI: Balance initial investment against long-term savings in labor, material, and increased productivity.

- Manufacturer Support: Consider warranty, training, and availability of technical support and spare parts.

Maintenance and Operational Considerations

To ensure longevity and optimal performance:

- Regular Lubrication: Keep moving parts, especially chains and gears, adequately lubricated.

- Tooling Inspection: Periodically check rollers for wear or damage, as this affects profile accuracy.

- Hydraulic System Maintenance: Check fluid levels and filters if equipped with a hydraulic cutting system.

- Calibration: Verify cutting length accuracy regularly and adjust PLC settings as needed.

- Operator Training: Ensure personnel are properly trained on operation, safety procedures, and basic troubleshooting.

Conclusion

Steel Stud & Track Roll Forming Machines are vital equipment in modern construction and manufacturing, enabling the efficient, precise, and cost-effective production of light gauge steel framing components. By automating the transformation of steel coil into structural studs and tracks, these machines support faster construction cycles, improve building quality, and reduce material waste, aligning perfectly with the demands for efficiency and sustainability in the building industry. Understanding their operation, benefits, and selection criteria allows businesses to leverage this technology effectively. For more information on steel framing standards, consult resources like the Steel Framing Industry Association (SFIA).