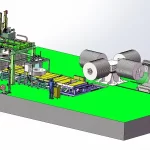

Steel coil packing lines are the backbone of many industrial operations, ensuring that heavy-duty coils are securely packaged and ready for transport. However, like any complex system, these lines require consistent maintenance to operate at peak performance. Neglecting this can lead to downtime, costly repairs, or even compromised product quality.

Our service packages are designed to cater to the specific needs of your operations, offering flexibility, efficiency, and long-term reliability. Whether you’re looking for routine upkeep or advanced diagnostics, we have a solution tailored to you. Let’s dive into what makes our maintenance packages stand out and why they’re a must for your business.

The reliability of your steel coil packing line directly impacts your productivity and bottom line. Routine maintenance ensures uninterrupted operations while preventing minor issues from escalating into significant problems. But what does it really take to maintain these systems effectively?

Our approach is rooted in understanding your unique challenges. Through tailored service packages, we ensure your equipment remains in top condition while minimizing disruptions to your workflow.

[claim]

A well-maintained steel coil packing line can reduce downtime by up to 50%, cut repair costs significantly, and enhance the lifespan of your equipment.

1. What Do Our Service Packages Cover?

Routine maintenance schedules

Regular maintenance forms the foundation of our service packages. These schedules are crafted to align with your operational hours and production cycles, ensuring minimal disruptions.

Maintenance includes essential tasks such as cleaning, lubrication, and calibration, which prevent wear and tear while maintaining optimal performance. With a structured schedule, you gain peace of mind knowing your machinery is always ready for action.

Diagnostic services and troubleshooting

Every piece of equipment faces occasional hiccups, but diagnosing issues early can save time and money. Our service packages include advanced diagnostic tools that identify potential problems before they cause significant disruptions.

These services leverage the latest technology to assess mechanical, electrical, and software components. Once detected, our team provides swift troubleshooting, keeping your operations running smoothly.

Emergency repair solutions

Breakdowns don’t follow a schedule, but our emergency repair solutions ensure you’re never left stranded. Available 24/7, these services provide rapid response times to address critical issues.

Our team of experts is equipped with the skills and tools to handle emergencies efficiently, reducing downtime and restoring your production line quickly.

2. How Do We Tailor Packages to Your Needs?

Evaluating operational demands

No two operations are alike, which is why we begin every partnership with a thorough evaluation of your specific needs. This involves assessing production volumes, operational hours, and the complexity of your equipment.

By understanding these factors, we can recommend service packages that align with your goals, whether you prioritize cost efficiency, uptime, or long-term durability.

Customizing service frequency

Your equipment’s workload determines how often it needs maintenance. Heavy-duty lines operating 24/7 require more frequent check-ups compared to those with intermittent use.

We adjust service frequencies to match these demands, ensuring your machines get the attention they need without unnecessary interruptions. This flexibility is a cornerstone of our packages, allowing you to adapt as your business grows.

Offering flexible upgrade options

As your business evolves, so do your equipment needs. Our service packages include the option to upgrade or modify plans, giving you the freedom to add services as required.

This adaptability ensures that you’re always covered, whether you’re expanding operations or integrating new technology. It’s a proactive approach to maintenance that grows alongside your business.

3. What Makes Our Maintenance Packages Cost-Effective?

Reducing unexpected repair expenses

Unexpected breakdowns are not only stressful but also costly. Our maintenance packages emphasize preventive care, which drastically reduces the chances of sudden failures.

Preventive care focuses on identifying wear-and-tear components before they fail, ensuring timely replacements. By avoiding costly repairs and prolonged downtimes, your operational costs decrease significantly over time.

Extending equipment lifespan

Steel coil packing lines are a significant investment, and maximizing their lifespan is a top priority for any business. Regular maintenance, performed by experts, ensures that your machinery operates at its best for years to come.

Our team’s attention to detail—cleaning, recalibrating, and inspecting critical components—protects your investment and delays the need for expensive replacements.

Improving energy efficiency

Efficient machinery consumes less energy, lowering operational costs. Routine maintenance optimizes performance, ensuring that motors, conveyors, and other components run smoothly.

By enhancing energy efficiency, your business not only saves on utility bills but also contributes to sustainability goals—a win for both your bottom line and the environment.

4. Why Should You Trust Our Expertise?

Decades of industry experience

When it comes to steel coil packing lines, expertise matters. With decades of experience in maintaining complex machinery, our team has seen and solved it all.

We combine technical knowledge with practical insights, offering solutions that are both effective and tailored to your unique requirements.

Certified and highly trained technicians

Our technicians are not just skilled—they’re certified professionals trained to handle even the most advanced steel coil packing lines.

They stay updated on industry advancements and emerging technologies, ensuring your equipment benefits from cutting-edge maintenance practices.

Proven track record of success

Numbers speak louder than words. Our clients consistently report improved equipment performance, reduced downtime, and significant cost savings after adopting our service packages.

Their success stories are a testament to our commitment to delivering results that matter.

Conclusion

Steel coil packing line maintenance is not just a routine task—it’s an investment in your business’s long-term success. From reducing downtime to extending equipment lifespan, the benefits are undeniable.

[claim]Our tailored service packages offer a blend of preventive care, expertise, and flexibility, ensuring your operations remain efficient and cost-effective. Partner with us today and experience the difference in reliability, performance, and peace of mind.

Get Your Best Solution !