A Semi-Auto Plastic Pipe Coiler is designed for efficient and reliable coiling of plastic pipes, such as those used for plumbing, irrigation, and industrial applications. This machine automates the task of coiling long lengths of pipe into neat, manageable rolls, simplifying both storage and transportation. The semi-automatic nature of the machine means that while some manual intervention is required, such as setting up the pipe dimensions and occasionally guiding the pipe into the coiler, the bulk of the coiling operation is automated. The machine typically features adjustable tension controls to handle different pipe diameters and materials, ensuring a tight and secure coil without damaging the pipe.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Semi-Automatic Plastic Pipe Coiler

- Compatible Pipe Materials: PVC, PE, HDPE

- Pipe Diameter Range: 20mm to 200mm

- Coil Inner Diameter: Adjustable from 500mm to 1500mm

- Operation Mode: Semi-Automatic with manual setup

- Coil Binding Options: Straps, stretch film

- Production Capacity: Up to 20 coils per hour

- Power Requirements: 220V, 50Hz, single phase

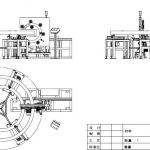

- Machine Dimensions: Length: 3000mm; Width: 1500mm; Height: 1200mm

- Machine Weight: Approximately 800kg

- Control System: Simple push-button operation with emergency stop

- Safety Features: Guardrails and safety sensors

Applications:

- In the field of agricultural irrigation, where long and flexible plastic pipes are required, the Semi-Auto Plastic Pipe Coiler proves invaluable. It allows for efficient coiling of pipes, which can then be securely wrapped and stored until needed. This machine ensures that the pipes are ready for quick deployment in the field, facilitating rapid setup of irrigation systems. The secure coiling prevents damage and kinks in the pipes, enhancing their longevity and performance in transferring water across vast agricultural fields.

- For building and construction projects, managing the logistics of plumbing materials, especially lengthy plastic pipes, is crucial. The Semi-Auto Plastic Pipe Coiler helps by automatically coiling pipes into a compact form. This makes transportation to the construction site more efficient and reduces storage space requirements on-site. Additionally, the coils are easier for workers to handle and deploy, speeding up the installation process and reducing the risk of pipe damage during handling.

- In industrial settings, where space and time are at a premium, the ability to quickly coil plastic pipes of varying diameters for different uses can greatly enhance operational efficiency. The Semi-Auto Plastic Pipe Coiler handles this task with ease, providing consistently tight and uniform coils. This not only facilitates better use of storage spaces but also improves the organization of supplies, allowing for quicker access and deployment in maintenance, manufacturing, and process setups, thus reducing downtime and increasing productivity.