Revolutionizing Aluminum Profile Packaging: The Ultimate Solution for Efficiency and Sustainability

Introduction

In today's rapidly evolving manufacturing landscape, the importance of efficient and sustainable packaging processes cannot be overstated. This is particularly true in the aluminum profile industry, where packaging plays a crucial role in protecting products during transportation and storage. For manufacturers and distributors in Poland, such as those in Nagradowice, the challenges associated with aluminum profile wrapping have long been a source of concern and inefficiency.

Traditional manual packaging methods for aluminum profiles are fraught with issues: inconsistent packaging quality, the need for frequent worker shift changes, high physical and psychological pressure on employees, messy workhouse layouts, elevated human costs, and suboptimal product output. These challenges not only impact productivity but also hinder sustainable development goals and the implementation of green company policies.

Enter the game-changing solution: the automatic horizontal stretch wrapper for aluminum profiles. This innovative machine is set to transform the industry by addressing these longstanding issues head-on.

Problem-Solution Framing

Polish manufacturers and distributors of aluminum profiles face a myriad of challenges in their packaging processes. The inefficiencies of manual wrapping systems result in inconsistent packaging quality, increased labor costs, and potential product damage. Moreover, the physical demands of the job lead to worker fatigue and potential health issues, necessitating frequent shift changes and resulting in reduced productivity.

The automatic horizontal stretch wrapper for aluminum profiles emerges as the definitive solution to these pressing problems. By automating the wrapping process, this advanced machinery dramatically improves efficiency, ensures consistent packaging quality, and significantly reduces the physical demands on workers. Let's explore how this solution transforms the packaging landscape:

Consistency and Quality:

The machine delivers uniform, high-quality packaging for every aluminum profile, eliminating the inconsistencies associated with manual wrapping.

24/7 Operation:

Unlike human workers, the automatic wrapper can operate round the clock, significantly boosting output and meeting demanding production schedules.

Reduced Labor Costs:

By automating the wrapping process, manufacturers can reallocate their workforce to more value-added tasks, optimizing labor utilization and reducing overall costs.

Improved Workplace Environment:

The machine eliminates the need for manual handling of profiles, reducing physical strain on workers and creating a cleaner, more organized workhouse layout.

Sustainability:

The precision of the machine in applying stretch wrap reduces material waste, aligning with green company policies and sustainable development goals.

Customization for Solution

The automatic horizontal stretch wrapper for aluminum profiles is designed with versatility in mind, catering to the specific needs of different manufacturers. For profiles measuring 8m in length, 0.5m in width, and 0.5m in height, the machine employs orbital stretch wrap packaging to ensure optimal protection.

The customization options available include:

- Adjustable Wrapping Tension: The machine can be fine-tuned to apply the ideal tension for different profile thicknesses and shapes, ensuring secure packaging without risk of damage.

- Variable Speed Settings: Operators can adjust the wrapping speed to accommodate different production rates or profile complexities.

- Programmable Wrapping Patterns: For profiles with unique features or sensitive areas, custom wrapping patterns can be programmed to provide targeted protection.

Industry-specific applications highlight the machine's versatility:

- Construction Industry: For manufacturers supplying aluminum profiles for building facades or window frames, the machine ensures that even long profiles are securely wrapped for safe transportation to construction sites.

- Automotive Sector: Suppliers of aluminum profiles for vehicle manufacturing can benefit from the machine's precision in protecting critical components.

- Furniture Manufacturing: Companies producing aluminum profiles for modern furniture designs can rely on the machine to preserve the aesthetic quality of their products during shipping.

- Solar Panel Frame Production: With the growing demand for solar energy, manufacturers of aluminum frames for solar panels can use the machine to meet high-volume packaging needs efficiently.

Key Features and Benefits

The automatic horizontal stretch wrapper for aluminum profiles boasts an array of features designed to address the specific needs of Polish manufacturers:

- High-Speed Operation: The machine can wrap profiles at a rate that far exceeds manual capabilities, significantly increasing throughput.

- Precision Tension Control: Adjustable wrapping tension ensures that each profile is secured with the appropriate pressure, preventing damage while ensuring adequate protection.

- User-Friendly Interface: An intuitive control panel allows for easy operation and quick adjustments, minimizing training time and reducing the likelihood of errors.

- Automatic Film Cutting and Sealing: This feature eliminates the need for manual intervention at the end of each wrapping cycle, further streamlining the process.

- Energy-Efficient Design: In line with sustainable development goals, the machine is designed to optimize energy consumption during operation.

- Compact Footprint: Despite its capabilities, the machine is designed to fit efficiently into existing workhouse layouts, minimizing disruption during installation.

The benefits of implementing an automatic horizontal stretch wrapper extend far beyond mere efficiency:

- Time Savings: The rapid wrapping speed and elimination of manual tasks result in dramatic time savings, allowing for increased production output.

- Cost-Effectiveness: Reduced labor requirements, lower material consumption, and decreased product damage all contribute to significant cost savings over time.

- Improved Product Safety: Consistent, tight wrapping provides superior protection against environmental factors and handling damage during transportation and storage.

- Enhanced Workplace Safety: By eliminating manual handling of heavy profiles and repetitive motions, the risk of workplace injuries is substantially reduced.

- Quality Consistency: Automated wrapping ensures that every profile receives the same high-quality packaging, regardless of operator fatigue or skill level.

- Increased Productivity: The speed and efficiency of the machine allow for higher throughput, enabling manufacturers to meet increased demand or tighter deadlines.

- Sustainability: Precise film application results in less material waste, contributing to both cost savings and environmental sustainability.

Real-World Examples

The impact of the automatic horizontal stretch wrapper for aluminum profiles is best illustrated through real-world applications. Consider the following case studies:

Efficiency Boost at xxxxxx.:

Before implementing the automatic wrapper, Nagradowice Aluminum Ltd. could package only 100 profiles per shift. After installation, their output increased to 300 profiles per shift - a 200% improvement in efficiency. This dramatic increase allowed them to meet growing market demands without expanding their workforce.

Labor Savings at Polish Profile Producers:

Polish Profile Producers previously required a team of 12 workers across three shifts to manually wrap their aluminum profiles. By implementing the automatic horizontal stretch wrapper, they were able to reduce this to just 3 operators per day, one for each shift. This led to a 75% reduction in packaging labor costs and allowed for the reallocation of skilled workers to other critical areas of production.

Management Improvement at xxxxx:

The management team at Warsaw Extrusions Inc. struggled with inconsistent packaging quality and difficulty in tracking production metrics. The introduction of the automatic horizontal stretch wrapper provided them with precise data on packaging times, material usage, and output rates. This wealth of information allowed for more accurate production planning and inventory management. As a result, the company saw a 40% improvement in overall operational efficiency within four months of implementation.

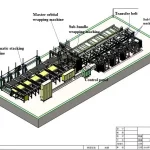

Visuals and Video Demonstration

To fully appreciate the capabilities of the automatic horizontal stretch wrapper for aluminum profiles, it's crucial to see the machine in action. A comprehensive video demonstration would showcase:

- The seamless loading process of aluminum profiles onto the machine conveyor.

- The precision of the orbital wrapping mechanism as it efficiently envelops profiles of various lengths.

- The automated film cutting and sealing process at the end of each cycle.

- The smooth ejection of the wrapped profile, ready for storage or shipping.

- A side-by-side comparison of manual wrapping versus the automatic process, highlighting the time and labor savings.

Such visual content not only illustrates the machine's efficiency but also helps potential buyers envision how it would integrate into their existing production lines.

Contact Us Now

Are you ready to revolutionize your aluminum profile packaging process? Our team of experts is standing by to help you explore how the automatic horizontal stretch wrapper can transform your operations. Here's how you can take the next step:

Schedule a Consultation: Book a one-on-one session with our product specialists to discuss your specific needs and how our solution can be tailored to your production line.

Request a Custom Quote: Provide us with details about your production volume and profile specifications, and we'll prepare a personalized quote for your business.

Arrange a Live Demo: See the automatic horizontal stretch wrapper in action at our showroom or through a virtual demonstration.

Access Detailed Specifications: Request our comprehensive product brochure for in-depth technical information and performance data.

Don't let outdated packaging methods hold your business back. Contact us today to step into the future of efficient, safe, and cost-effective aluminum profile packaging.

FAQs

1. Is the automatic horizontal stretch wrapper compatible with our existing production line?

Our machine is designed for seamless integration with most standard production lines. Our technicians can assess your current setup and recommend any necessary adjustments for optimal performance.

2. How long does installation and training take?

Typically, installation can be completed within 2-3 days, depending on your facility's layout. We provide comprehensive training for your operators, usually completed within an additional 1-2 days.

3. What type of maintenance does the machine require?

The automatic horizontal stretch wrapper is designed for minimal maintenance. Routine checks and lubrication are recommended weekly, with more comprehensive servicing suggested every six months. We provide detailed maintenance schedules and offer service contracts for peace of mind.

4. Can the machine handle different sizes of aluminum profiles?

Yes, our machine is designed to accommodate a range of profile sizes. The standard configuration handles profiles up to 8m in length, but custom solutions for longer profiles are available upon request.

5. What kind of warranty do you offer?

We provide a standard 2-year warranty on all parts and labor. Extended warranty options are available for additional coverage.

6. How quickly can we expect to see a return on investment?

While this varies depending on your production volume and current processes, many of our clients report significant cost savings within the first 4-6 months of operation, with full ROI often achieved within 12-18 months.

7. Is the machine compliant with Polish and EU safety regulations?

Absolutely. Our automatic horizontal stretch wrapper meets and exceeds all relevant Polish and EU safety standards for industrial machinery. We provide full documentation to ensure smooth compliance with local and international regulations.