Real-World Applications and Advantages of Steel Coil Packing Lines in Heavy Industry

Steel coil packing lines are indispensable assets in heavy industry, providing crucial protection and facilitating the safe, efficient transport of valuable steel products. These automated systems are fundamental to sectors like construction, automotive manufacturing, and shipbuilding, which handle vast quantities of steel coils daily. With global steel demand consistently high, optimizing the steel coil packing process is more vital than ever. This article delves into the real-world applications of steel coil packing lines, highlighting their significance in heavy industry and exploring the benefits they offer in terms of operational efficiency, product protection, workplace safety, and cost savings.

The Increasing Importance of Efficient Steel Coil Packaging Solutions

Steel forms the bedrock of modern infrastructure and manufacturing. Steel coils, specifically, are versatile raw materials used extensively across numerous industries. From constructing towering skyscrapers and expansive bridges to manufacturing vehicles and industrial machinery, high-quality steel is essential. As global steel consumption grows, manufacturers face the critical challenge of safeguarding these coils—often worth thousands of dollars each—during storage and transit. This is where advanced steel coil packing lines provide an essential solution.

An optimized packing line achieves two primary goals: it meticulously protects the steel's integrity and enhances overall productivity by automating and streamlining the packaging workflow. In heavy industries, where precision and reliability are paramount, automated packing lines significantly boost efficiency while mitigating costs associated with product damage, manual labor inefficiencies, and operational downtime. Crucially, modern steel coil packing lines can be tailored to meet the specific handling and protection requirements of diverse industries, ensuring products arrive at their destination in optimal condition.

We will now explore the specific applications, key benefits, and essential features of steel coil packing lines, examining their transformative impact on heavy industry logistics and manufacturing processes.

1. Why Robust Steel Coil Packing is Non-Negotiable in Heavy Industry

Heavy sectors like construction, automotive manufacturing, and aerospace rely fundamentally on steel coils for their core operations. These coils, often weighing several tonnes, represent significant investments. Even seemingly minor damage incurred during handling or transport—such as scratches, dents, edge damage, or corrosion—can lead to substantial financial losses and production delays. Steel coil packing lines are essential because they provide an automated, reliable method to shield these valuable products from numerous hazards, including:

- Physical Damage: Impacts, abrasions, scratches, and edge damage during handling and transit.

- Environmental Factors: Moisture, humidity, dust, and contaminants leading to rust and corrosion.

- Handling Issues: Damage resulting from improper lifting, stacking, or securing.

Compared to manual packaging methods, which can be inconsistent and labor-intensive, automated packing lines deliver a uniform and dependable wrapping process. This consistency ensures every steel coil receives the same high level of protection, significantly enhancing product safety. Furthermore, automation accelerates the entire packaging cycle, enabling companies to process larger volumes of steel more efficiently and with fewer human resources. Consequently, businesses employing these systems are better positioned to meet escalating market demands for steel products worldwide.

2. Boosting Operational Efficiency with Automated Steel Coil Packing Lines

In any competitive industrial environment, operational efficiency is a critical driver of success. Automated steel coil packing lines are engineered to optimize the entire packaging workflow, dramatically reducing reliance on manual labor and minimizing costly downtime. By automating core tasks such as coil handling, protective wrapping, strapping (using materials like PET or steel bands), weighing, and labeling, these systems substantially increase throughput, allowing companies to ship products faster and more reliably.

Key efficiency benefits include:

- Continuous Operation: Ability to operate 24/7 with minimal supervision, maximizing plant productivity.

- Reduced Labor Costs: Less need for manual intervention in repetitive or strenuous tasks.

- Minimized Human Error: Consistent application of packaging materials ensures uniform quality and reduces the risk of improperly secured coils.

- Faster Throughput: Streamlined processes lead to quicker packaging cycles per coil.

Furthermore, modern automated packing lines often feature intelligent control systems (PLCs) and Human-Machine Interfaces (HMIs). These allow manufacturers to monitor the process in real-time, adjust parameters easily, track production data, and receive alerts for potential issues (e.g., material depletion, wrapping faults). This proactive monitoring capability prevents costly errors and further optimizes production line efficiency. Some advanced lines also integrate robotic systems for tasks like label application or palletizing.

3. Minimizing Product Damage and Material Waste During Steel Coil Transit

A primary function of steel coil packing lines is to drastically reduce the risk of product damage during the entire logistics chain—from factory storage to final delivery. Whether transported via truck, train, or ship, steel coils face numerous environmental and physical challenges. Inadequately packed coils are highly susceptible to:

- Corrosion: Rust formation due to exposure to moisture, humidity, or corrosive atmospheres (especially sea freight).

- Surface Damage: Scratches, abrasions, and dents from impacts or friction.

- Edge Damage: Vulnerable coil edges can be easily bent or damaged.

- Coil Telescoping/Shifting: Improperly secured coils can shift or deform during transit.

Automated packing lines utilize a combination of high-performance packaging materials tailored to the specific risks involved. Common materials include:

- Stretch Film: Provides containment, stability, and protection against dust and moisture.

- VCI (Vapor Corrosion Inhibitor) Paper/Film: Releases chemicals that form a protective molecular layer on the steel surface, preventing rust even in humid conditions.

- Edge Protectors: Cardboard, plastic, or metal protectors shield vulnerable coil edges.

- Strapping: Steel or high-strength PET (polyester) bands secure the coil and packaging materials.

- Outer Wraps: Additional layers like waterproof paper or plastic sheeting for enhanced environmental protection.

By applying these materials correctly and consistently, automated lines ensure robust protection against both physical damage and environmental corrosion. This significantly reduces product rejection rates and material waste, yielding substantial financial savings and promoting environmental sustainability.

4. Application Spotlight: Steel Coil Packing Lines in the Automotive Industry

The automotive industry is a major consumer of high-quality steel coils, used for manufacturing vehicle bodies, chassis components, panels, and structural parts. The quality standards are exceptionally high, as surface defects or corrosion can compromise vehicle safety and aesthetics. Steel coils are frequently transported over long distances, often internationally, to reach automotive assembly plants. Consequently, automotive manufacturers depend heavily on effective steel coil packing lines to guarantee that these critical materials arrive in pristine condition, ready for stamping and assembly processes.

Given the immense volume of steel consumed in vehicle production (the global automotive industry uses over 100 million tonnes of steel annually, according to sources like the World Steel Association), automotive companies require highly efficient packing systems capable of processing numerous coils daily. Automated steel coil packing lines meet this need, enabling manufacturers to maintain high production tempos without sacrificing packaging quality. These lines are typically configured to handle the specific coil sizes, weights, and surface finish requirements common in the automotive sector, often incorporating specialized VCI materials and stretch films to prevent cosmetic defects and corrosion during extended storage or transit.

The robust protection afforded by automated packing prevents moisture and contaminants from compromising the steel surface. This is especially critical for coils shipped across varying climates or stored before use. Secure, high-quality packaging helps automotive companies avoid costly production line stoppages, material waste, and defects in finished vehicles.

Get Your Best Solution !

5. Application Spotlight: Steel Coil Packing Needs in the Construction Sector

In the vast construction industry, steel is a fundamental material for building everything from bridges, high-rises, and industrial facilities to residential framing and roofing. Steel coils are processed into structural sections, reinforcing bars (rebar), roofing panels, cladding, and ductwork. Ensuring the safe and efficient delivery of these steel materials to diverse and often challenging job sites is a top priority. Steel coil packing lines assist construction material suppliers and steel service centers in streamlining their logistics by providing secure, weather-resistant packaging suitable for transport and on-site storage.

Construction projects frequently expose materials to harsh environmental conditions, including rain, snow, humidity, dust, and extreme temperatures. Appropriate packaging is therefore essential to shield steel coils from corrosion and physical damage before they are incorporated into structures. Automated steel coil packing lines not only wrap coils efficiently but also ensure the packaging specifications (e.g., using waterproof wraps, VCI materials, robust strapping) are suited to the anticipated storage conditions and duration at the construction site.

By utilizing automated packing systems, suppliers can significantly reduce the risk of delivering damaged steel to a project site. Damaged materials can lead to costly project delays, rework, and disputes. Reliable packaging ensures that construction companies receive steel ready for immediate use, helping them maintain project timelines and budgets.

6. Application Spotlight: Tailoring Steel Coil Packing for the Shipbuilding Industry

The shipbuilding industry consumes enormous quantities of steel, primarily heavy-gauge plates derived from steel coils, for constructing ship hulls, decks, bulkheads, and other structural components. The steel used in shipbuilding must meet stringent quality and durability standards. Given the scale and weight of these materials, specialized handling and robust packaging are necessary to maintain steel integrity throughout the supply chain. Steel coil packing lines are crucial in this sector, providing an efficient and reliable method to package and protect the heavy-duty steel used in vessel construction.

A key challenge in shipbuilding logistics is the frequent need for long-distance sea transport. Steel coils shipped by sea are exposed to highly corrosive saltwater spray and humid marine atmospheres. Therefore, packaging must provide exceptional resistance to saltwater corrosion. Steel coil packing lines serving the shipbuilding sector are often equipped to apply specialized packaging solutions, such as multi-layer wraps incorporating heavy-duty VCI films or papers, laminated barrier foils, and tightly sealed outer coverings, creating a highly effective moisture and salt-resistant barrier.

Furthermore, the sheer size and weight of steel coils destined for shipbuilding necessitate heavy-duty packing lines. These systems are engineered with reinforced structures, powerful handling mechanisms, and robust strapping systems (often using heavy-gauge steel bands) capable of securely managing coils that can weigh dozens of tonnes. This ensures the coils remain stable and protected throughout rigorous sea voyages and shipyard handling.

7. The Central Role of Automation in Modern Steel Coil Packaging

Automation is the cornerstone of modern steel coil packing line performance. Historically, packaging processes involved significant manual labor, which was slow, physically demanding, inconsistent, and posed safety risks. The integration of automation has revolutionized steel coil packaging, making it faster, more precise, highly reliable, and significantly safer.

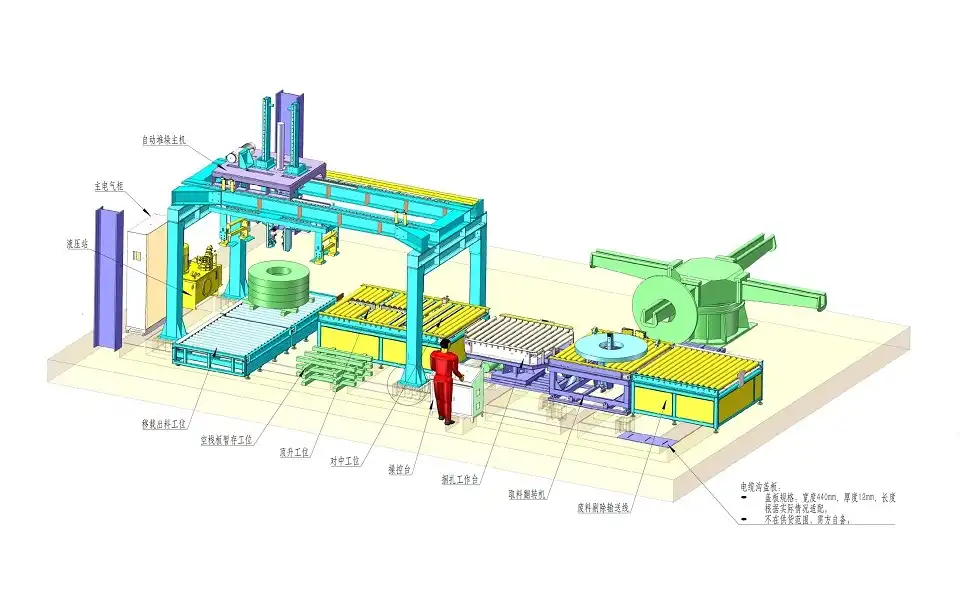

Fully automated packing lines can seamlessly manage the entire sequence of operations:

- Receiving coils from production lines or storage.

- Centering and preparing the coil for wrapping.

- Applying inner wraps (e.g., VCI paper).

- Applying main protective wraps (e.g., stretch film, waterproof paper).

- Applying edge protection.

- Strapping the coil (radially and/or circumferentially).

- Weighing the packed coil.

- Printing and applying labels.

- Transferring the packed coil to dispatch or storage areas (potentially involving robotic stacking).

These systems are designed for continuous, high-throughput operation, enabling manufacturers to meet demanding production schedules. Their programmability allows easy adaptation to different coil dimensions (width, diameter, weight) and varying packaging specifications, providing flexibility for diverse industrial needs. Integrated sensors and control systems provide real-time feedback, diagnostics, and automated adjustments, minimizing downtime and ensuring consistent packaging quality.

8. Customizing Steel Coil Packing Lines for Specific Industry Needs

A significant advantage of contemporary steel coil packing lines is their adaptability. Recognizing that different industries and even different products within an industry have unique requirements, manufacturers can customize packing lines extensively. Key areas for customization include:

- Coil Handling Capacity: Systems designed for specific ranges of coil diameters, widths, and weights (from light coils for appliances to massive coils for shipbuilding).

- Packaging Materials: Dispensers and applicators configured for various materials like different grades of stretch film, VCI types, papers, foils, edge protectors, and strapping (PET vs. steel, number and position of straps).

- Level of Automation: Ranging from semi-automated lines requiring some operator input to fully automated, integrated systems with robotics.

- Layout and Footprint: Modular designs allow configurations to fit existing plant layouts and space constraints.

- Control Systems Integration: Linking the packing line controls with plant-wide Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems for data exchange and process visibility.

- Environmental Considerations: Options for using recyclable materials or minimizing packaging waste.

For instance, a line for the automotive industry might prioritize surface protection using specific films and careful handling, while a line for the construction sector might focus on robust weatherproofing and heavy-duty strapping. This ability to tailor the solution ensures optimal performance, cost-effectiveness, and product protection for each unique application.

9. Enhancing Workplace Safety through Automated Steel Coil Packing

Workplace safety is a paramount concern in heavy industry, particularly where large, heavy materials like steel coils are handled. Manual packaging operations often involve risks associated with lifting, moving, strapping, and working near heavy coils. Automated steel coil packing lines significantly enhance workplace safety by removing workers from potentially hazardous tasks.

Key safety improvements include:

- Reduced Manual Handling: Automation minimizes or eliminates the need for workers to manually lift, push, or manipulate heavy coils or packaging materials, reducing risks of musculoskeletal injuries.

- Minimized Exposure to Moving Parts: Workers interact less directly with heavy machinery components like wrappers, strappers, and conveyors.

- Integrated Safety Features: Modern lines incorporate safety guarding, light curtains, emergency stops, sensors, and interlocks designed to halt operations immediately if an unsafe condition is detected.

- Consistent Procedures: Automation eliminates variability in manual procedures, reducing the chance of accidents caused by human error or shortcuts.

By automating dangerous aspects of the packaging process, companies can create a safer working environment, leading to fewer accidents, reduced injury rates, and lower associated costs like workers' compensation claims.

10. Conclusion: The Essential Future of Steel Coil Packing Lines in Heavy Industry

As global demand for steel products persists across vital sectors like construction, automotive, shipbuilding, and appliance manufacturing, the role of efficient, reliable, and automated steel coil packing lines becomes increasingly critical. These systems deliver a powerful combination of benefits – from enhanced operational throughput and significantly reduced product damage to improved workplace safety and cost savings – making them indispensable tools for modern heavy industry.

Investing in advanced steel coil packing technology enables companies to protect their valuable assets, streamline logistics, meet stringent quality requirements, and maintain a competitive edge. The customizability and adaptability of these lines ensure they can be precisely tailored to meet diverse industrial needs. Looking ahead, further advancements in automation, robotics, sensor technology, data analytics, and sustainable packaging materials will continue to evolve steel coil packing lines, cementing their status as a vital component of efficient and safe industrial operations worldwide.

Get Your Best Solution !