The prestressed with is heavy and big size that is no easy packing by manually.

There are two main types pre-stressed steel wire coil packing machine produced by FHOPE to help improving the packing speed and wire coil protection.

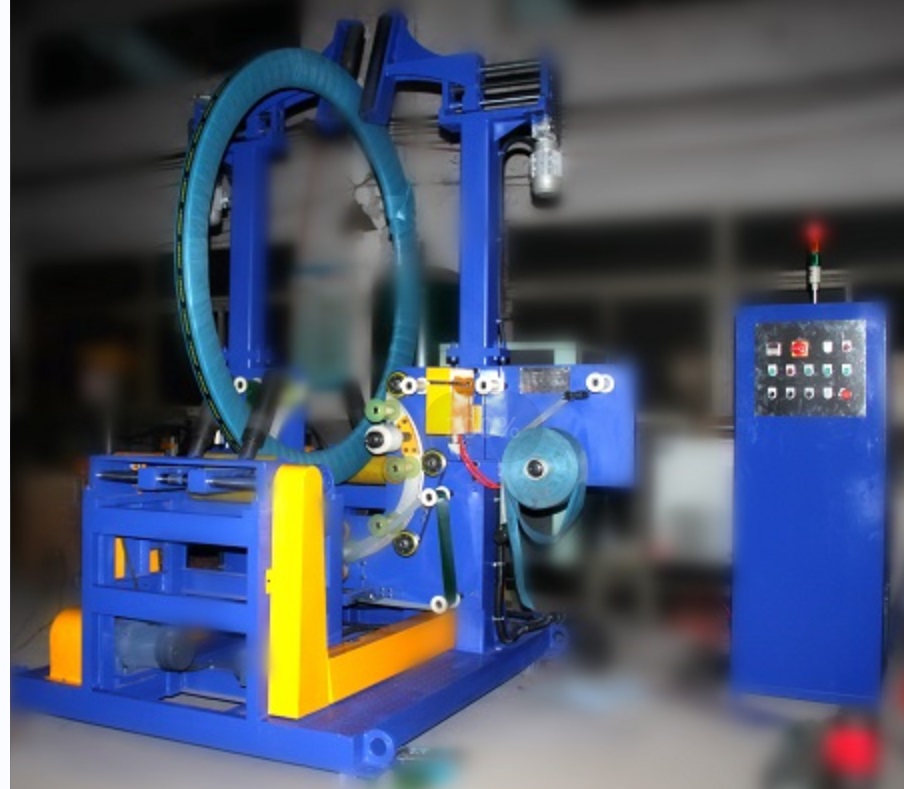

A. vertical version prestress wire coil packing machine

This is the vertical version prestressed wire packing machine.

Since the OD of the prestressed wire coil is upto 2000mm mornally, the disadvantage of vertical wire coil packing machine is the height of the operation. The machine height is app. 1800-2200mm. Adding the coil height, the handling height is app. 4000mm. And the top point of the coil on the machine for wrapping is app. 3000-3500mm.

That may too height for the operator by carne.

In the video, the prestressed wire coil packing machine was put into the pit that for keeping the wire coil working table same as floor. By this way the wire coil handling is more easy and safety by manually loading with crane.

Vertical Type:

• The coil is loaded vertically onto the machine in its normal winding orientation.

• A rotating ring or carousel wraps stretch film around the vertical coil to secure it.

• Film tensioning systems like idler rolls or powered film unwind help achieve a tight wrap.

• The vertical orientation allows for a compact machine footprint. However, coils are heavier to handle in this position.

• Changing coil diameters typically requires manual adjustment of film guides and tensioners.

• Suitable for medium to high production volumes with continuous operation.

B. Horizontal prestress wire coil packing machine

a. The roller station fixed solution

This is an horizontal type prestress wire coil packing machine.

This is the horizontal type wire coil packing for the OD>2000mm. It includes the roller table and wrapping station for eye through wrapping. The wrapping station is movable for in and out the wrapping position that is for easy coil loading and unloading from top of the table by crame.

For easy loading the wire coil with big OD, there some special clampers aviable for working with crane.

More wire coil packing solutions: https://www.fhopepack.com/Wire-coil-wrapping-machine/

b. The roller station adjustment solution

The video of the PC wire coil packing machine for big range OD adjustment that makes the machine works for wire coil OD:1000-2500mm. And it is possible for OD1500-3500mm, or even bigger. The main feacture is the 4 supportive rolls with lead screw and drived with motor which can be shrink and extand per different coil OD.

This is the kind of solution for super big coil OD packaging such as PC wire, bearing,flange…

Horizontal Type:

• The coil is loaded horizontally onto support rollers in a ‘lying down’ position.

• A rotating arm or pivot mechanism then extends over the coil to apply the stretch film wrap.

• The horizontal position makes loading and unloading coils easier using forklifts or cranes.

• However, achieving sufficient film tension can be challenging since gravity does not aid in pulling the film tight.

• Properly designed film unwind and tensioning systems are important for consistent wrapping results.

• Coil support rollers are often padded to prevent scratching of the coil surface during rotation.

• Quick changeover between coil diameters is easier since the coil remains in a fixed position.

• Best suited for lower production volumes due to slower wrapping cycle times.

So in summary, while vertical wrappers offer a more compact design and higher speeds, horizontal machines provide easier coil handling and faster changeover. Both types aim to secure prestressed steel wire coils using an optimized stretch film wrapping technique.