Enhancing Panel Packaging: Understanding Orbital Stretch Wrappers with Integrated Strapping

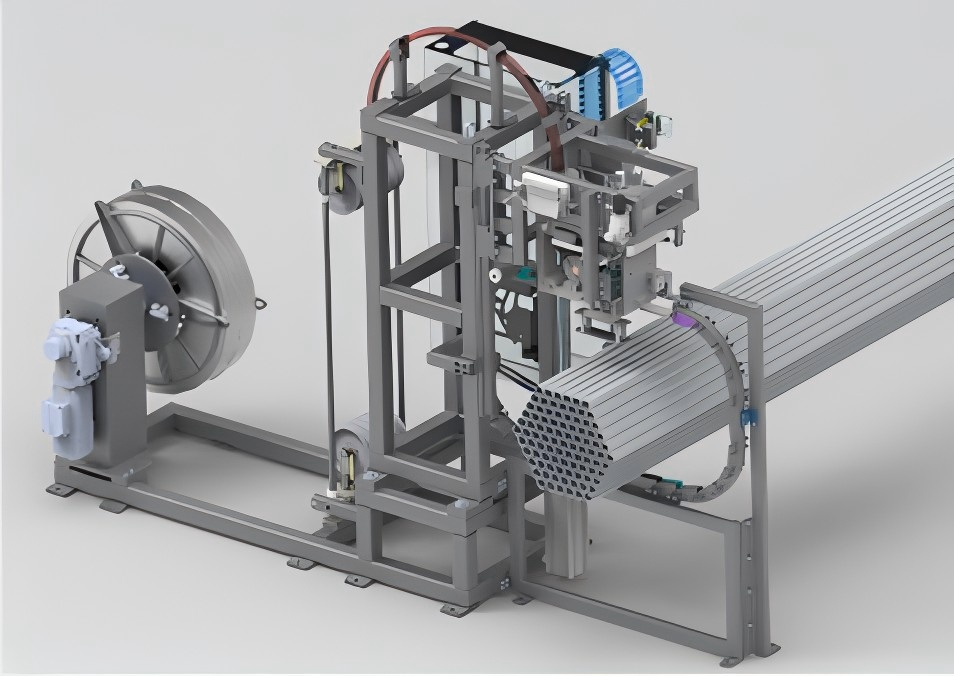

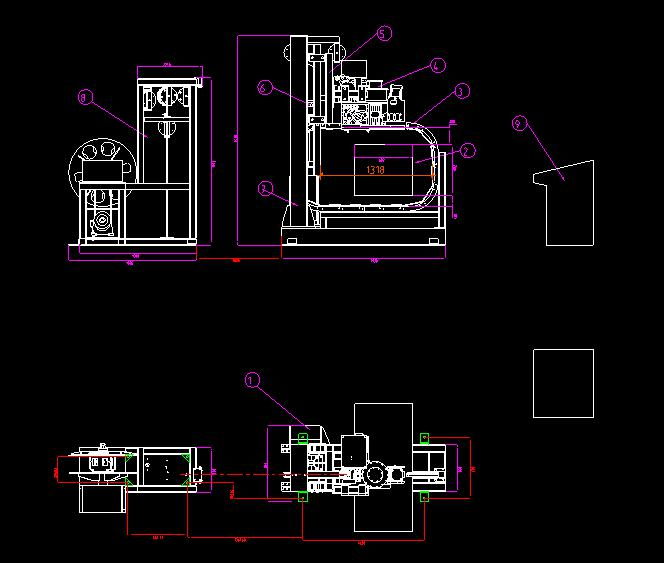

Handling large panels, such as sheet metal, wood composites, or fabricated assemblies, presents unique challenges in manufacturing and fabrication environments. Ensuring these items are securely packaged for safe transport and storage is crucial to prevent damage and maintain product integrity. An effective solution gaining traction in the industry is the combined panel orbital stretch wrapper with an integrated strapping machine.

How Panel Orbital Wrappers with Strapping Work

This specialized equipment automates the process of securing panels for shipment or warehousing. The typical operational flow involves several key steps:

- Infeed: Panels are fed onto the machine, usually via an integrated conveyor system. Sensors often ensure proper positioning before the packaging cycle begins.

- Orbital Wrapping: The panel moves through (or is stationary while a wrapping ring rotates around) the core wrapping section. A rotating ring dispenses plastic stretch film, wrapping it securely around the panel's perimeter. This orbital motion ensures consistent coverage even for long items.

- Stretch Film Application: The stretch film is applied under controlled tension, creating a tight, protective layer that conforms to the panel's shape. This helps unitize stacked panels and protects surfaces from dust, moisture, and minor abrasions.

- Integrated Strapping: Once wrapping is complete, an integrated strapping unit applies one or more straps (typically PET or steel) circumferentially or longitudinally around the wrapped panel. This adds significant load stability and prevents shifting during handling.

- Outfeed: The fully wrapped and strapped panel exits the machine, ready for removal or transfer to the next stage (e.g., warehousing, shipping dock).

panel shrink packing machine3、 Key Components and Capabilities

These automated packaging systems are designed for industrial use and typically feature:

- Conveyor System: Facilitates smooth entry and exit of panels. Can be roller or belt-based, depending on panel characteristics.

- Rotating Wrapping Ring: Houses the stretch film roll and dispensing mechanism. Its diameter determines the maximum panel cross-section the machine can handle.

- Film Carriage: Controls the pre-stretch and tension of the film application, optimizing material usage and wrap security.

- Strapping Head: Applies, tensions, seals, and cuts the strap automatically. Different heads accommodate various strap types and sizes.

- Control System: PLC-based controls allow operators to set parameters like wrap counts, strap positions, tension levels, and conveyor speed. May include touchscreen interfaces.

- Safety Features: Guarding, emergency stops, and interlocks are standard to protect operators.

These machines can often be customized to handle a wide range of panel dimensions (length, width, height) and weights.

Benefits in Fabrication and Manufacturing

Integrating a panel orbital stretch wrapper with strapping offers several advantages:

- Enhanced Product Protection: The combination of stretch wrap and strapping provides superior protection against scratches, moisture, and shifting compared to manual methods or wrapping/strapping alone.

- Improved Load Stability: Securely unitized panels are less likely to shift or collapse during transit, reducing the risk of damage and improving safety during loading/unloading.

- Increased Throughput: Automation significantly speeds up the packaging process compared to manual wrapping and strapping, boosting overall operational efficiency.

- Reduced Labor Costs: Automating the wrapping and strapping tasks frees up personnel for other value-added activities.

- Material Savings: Precise control over stretch film tension and application can optimize material consumption.

- Consistency: Automated systems ensure every panel is packaged to the same standard, improving quality control.

steel strapping machine Operational Considerations and Safety

Proper operation and maintenance are vital for maximizing the benefits and ensuring safety:

- Operator Training: Personnel must be thoroughly trained on the machine's operation, safety protocols, and basic troubleshooting.

- Safety Protocols: Always adhere to manufacturer safety guidelines, including lockout/tagout procedures during maintenance. Ensure all safety guards are in place during operation.

- Personal Protective Equipment (PPE): Operators may need gloves and safety glasses, especially when handling panels or performing maintenance.

- Regular Maintenance: Scheduled inspections and preventive maintenance (lubrication, checking wear parts like belts, cutters, sealing elements) are crucial for reliable performance and longevity.

- Machine Suitability: Ensure the chosen machine's specifications (panel size capacity, speed, strapping type) match the application's requirements.

Conclusion

For industries handling large volumes of panels, the panel orbital stretch wrapper with an integrated strapping machine represents a significant upgrade in packaging technology. By automating these critical processes, fabricators and manufacturers can achieve higher levels of product protection, load security, and operational efficiency, ultimately contributing to a smoother and more reliable supply chain.

Further Information:

- For details on example system configurations, see information on automatic panel packaging lines: http://www.fhopepack.com/Automatic-panel-packaging-line.html

- Explore related equipment like horizontal wrapping machines: https://www.fhopepack.com/Horizontal_wrapping_machine.html