Pallet Inverter ROI: Calculating the Return on Investment for Your Material Handling Operations

Investing in a pallet inverter can significantly enhance operational efficiency and yield substantial cost savings for businesses involved in material handling. However, justifying such an investment requires a clear understanding and calculation of its Return on Investment (ROI). This guide details how to calculate the ROI for a pallet inverter, explores the key factors influencing this calculation, and outlines the long-term benefits this essential equipment can bring to your operations.

1. Understanding Pallet Inverters: Functionality and Importance

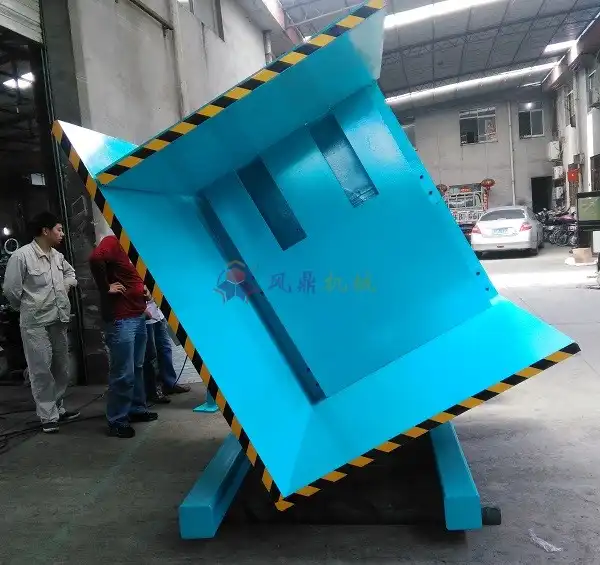

A pallet inverter, also known as a pallet exchanger or load transfer system, is specialized material handling equipment designed to rotate palletized loads up to 180 degrees. This allows for the swift and safe exchange of pallets—ideal for transferring loads from wood to plastic pallets, swapping out damaged pallets, or recovering products from the bottom of a stack without manual unloading.

Key Applications:

- Warehousing and Distribution Centers

- Food and Beverage Production

- Pharmaceutical Manufacturing

- Chemical Handling

- General Manufacturing

The adoption of pallet inverters is increasing alongside automation trends in logistics and supply chains. In high-volume environments, the ability to quickly, safely, and efficiently transfer loads between pallets translates directly into time savings, reduced labor costs, and minimized product damage.

2. Key Factors Influencing Pallet Inverter ROI

Calculating the ROI involves comparing the initial investment against the ongoing savings and operational improvements. Several factors are critical:

- Initial Investment Cost: This includes the purchase price of the specific pallet inverter model (which varies based on capacity, features, and level of automation), plus associated costs like shipping, installation, and initial operator training.

- Labor Cost Reduction: This is often the most significant saving. Automating or semi-automating the pallet exchange process reduces the manual labor hours required, potentially reallocating staff to more value-added tasks. It also decreases the risk of musculoskeletal injuries associated with manual handling, potentially lowering workers' compensation claims and insurance premiums.

- Operational Efficiency Gains: Quantify the time savings per pallet exchange cycle. Faster transfers reduce bottlenecks, shorten turnaround times, and increase overall throughput. Calculate the value of this saved time based on labor rates or increased output capacity.

- Reduced Product Damage: Manual handling increases the risk of dropping or damaging goods. Pallet inverters offer a controlled, secure method for load transfer, significantly reducing product loss and associated costs (spoilage, rework, disposal). This is especially critical for fragile or high-value items.

- Pallet Cost Management: Enables easy transfer to cheaper shipping pallets or switching to required customer/internal standard pallets (e.g., hygienic plastic pallets), avoiding rental costs or non-compliance fees.

- Maintenance and Operating Costs: Factor in the ongoing costs for electricity, routine maintenance (lubrication, inspections), and potential repairs over the machine's expected lifespan. High-quality, durable machines typically have lower long-term operating costs.

moible pallet changing machine for heavy load2 3. How to Calculate the ROI for Your Pallet Inverter

The standard formula for calculating ROI is:

ROI (%) = [ (Annual Net Savings - Total Initial Investment) / Total Initial Investment ] x 100

For a multi-year perspective, or to calculate the Payback Period:

Payback Period (Years) = Total Initial Investment / Annual Net Savings

Here’s a step-by-step guide:

Step 1: Determine the Total Initial Investment

Sum all upfront costs associated with acquiring and implementing the pallet inverter:

- Purchase Price: e.g., $50,000

- Shipping & Installation: e.g., $3,000

- Operator Training: e.g., $2,000

- Total Initial Investment: $55,000

Step 2: Estimate Annual Net Savings

Calculate the total financial benefits gained per year, minus ongoing operational costs:

- Annual Labor Savings: (Hours Saved per Day) x (Operating Days per Year) x (Loaded Labor Rate)

- Example: Saving 2 hours/day x 250 days/year x $30/hour = $15,000

- Annual Reduced Product Damage Savings: (Value of Goods Damaged Annually Before) - (Value of Goods Damaged Annually After)

- Example: Saving $8,000 per year

- Annual Operational Efficiency Gains (Throughput/Time): Value of increased output or saved time.

- Example: $7,000 per year

- Annual Pallet Management Savings: Savings from using optimal pallets or avoiding fees.

- Example: $5,000 per year

- Total Annual Gross Savings: $15,000 + $8,000 + $7,000 + $5,000 = $35,000

- Annual Operating & Maintenance Costs: Estimated cost for power, preventive maintenance, parts.

- Example: $2,000 per year

- Annual Net Savings: $35,000 (Gross Savings) - $2,000 (Operating Costs) = $33,000

Step 3: Calculate ROI and Payback Period

Using the figures from our example:

-

First-Year ROI: [ ($33,000 - $55,000) / $55,000 ] x 100 = -40%

- Note: A negative ROI in the first year is common due to the initial investment. The value lies in subsequent years.

-

Payback Period: $55,000 / $33,000 = 1.67 Years

- This means the investment recoups its cost in approximately 1 year and 8 months. After this point, the annual net savings contribute directly to profit.

Get Your Best Solution !

4. Long-Term Benefits Beyond Simple ROI

While the ROI calculation provides a quantitative measure, pallet inverters offer significant long-term strategic advantages:

- Enhanced Workplace Safety: Reducing manual lifting of heavy or awkward loads directly contributes to a safer work environment, aligning with health and safety regulations and improving employee morale. OSHA often cites manual material handling as a leading cause of workplace injuries.

- Improved Scalability: As your business volume grows, a pallet inverter can handle increased throughput without proportional increases in labor, making your operation more scalable.

- Increased Quality Control: Ensures products are handled consistently and gently, maintaining package integrity and meeting quality standards demanded by customers.

- Operational Flexibility: Allows quick adaptation to different pallet types (wood, plastic, CHEP, internal slip-sheets) required for various customers, suppliers, or internal processes.

- Reduced Employee Turnover: Automating strenuous tasks can lead to higher job satisfaction for warehouse staff, potentially reducing turnover and associated recruitment/training costs.

- Sustainability: Minimizing product damage reduces waste. Efficient handling can also contribute to lower energy consumption compared to prolonged manual processes.

5. Common Pitfalls When Evaluating Pallet Inverter ROI

Avoid these common mistakes for an accurate assessment:

- Focusing Only on Purchase Price: Overlooking installation, training, and potential facility modification costs can lead to an underestimated initial investment.

- Underestimating Savings: Failing to quantify all benefits, such as reduced damage, improved throughput value, and safety-related savings (insurance, compensation claims), can inaccurately deflate the ROI.

- Ignoring Operating Costs: Forgetting to factor in ongoing electricity, maintenance, and potential spare parts costs will overestimate the net savings.

- Choosing the Wrong Machine: Selecting an inverter that is undersized, oversized, or lacks necessary features for your specific application can limit potential gains and negatively impact ROI. Consider load types, weights, frequency, and integration needs.

- Neglecting Long-Term Value: Focusing solely on a short payback period might undervalue the substantial cumulative savings and operational improvements over the equipment's entire 10-15+ year lifespan.

6. Maximizing the Return on Your Pallet Inverter Investment

Once installed, maximize your ROI through:

- Consistent Preventive Maintenance: Follow the manufacturer's recommended maintenance schedule to ensure optimal performance, minimize unexpected downtime, and extend the equipment's lifespan.

- Thorough Operator Training: Ensure all operators are properly trained on safe and efficient operation. Well-trained staff use the machine correctly, reducing errors, potential damage, and maximizing cycle speed.

- Process Integration: Integrate the pallet inverter smoothly into your existing workflow. Analyze upstream and downstream processes to eliminate bottlenecks and ensure the inverter operates at its full potential.

- Performance Monitoring: Track key metrics like cycles per hour, downtime, and instances of product damage avoided to continually verify and potentially improve upon the initial ROI projections.

pallet inverter factory (8) Conclusion: Is a Pallet Inverter a Worthwhile Investment?

Calculating the ROI is crucial when considering a pallet inverter. While the initial investment cost can be significant, the long-term savings derived from reduced labor, minimized product damage, enhanced operational efficiency, and improved safety often provide a compelling financial justification.

By carefully analyzing your specific operational needs, accurately estimating costs and savings, and considering the long-term strategic benefits, you can make an informed decision. A properly selected, implemented, and maintained pallet inverter typically offers a strong ROI, paying for itself relatively quickly and contributing positively to your bottom line for many years. It's not just an equipment purchase; it's an investment in a more efficient, safer, and profitable material handling operation.

Get Your Best Solution !