Ensuring Flawless Operation: The Importance of Quality in Steel Coil Packing Lines

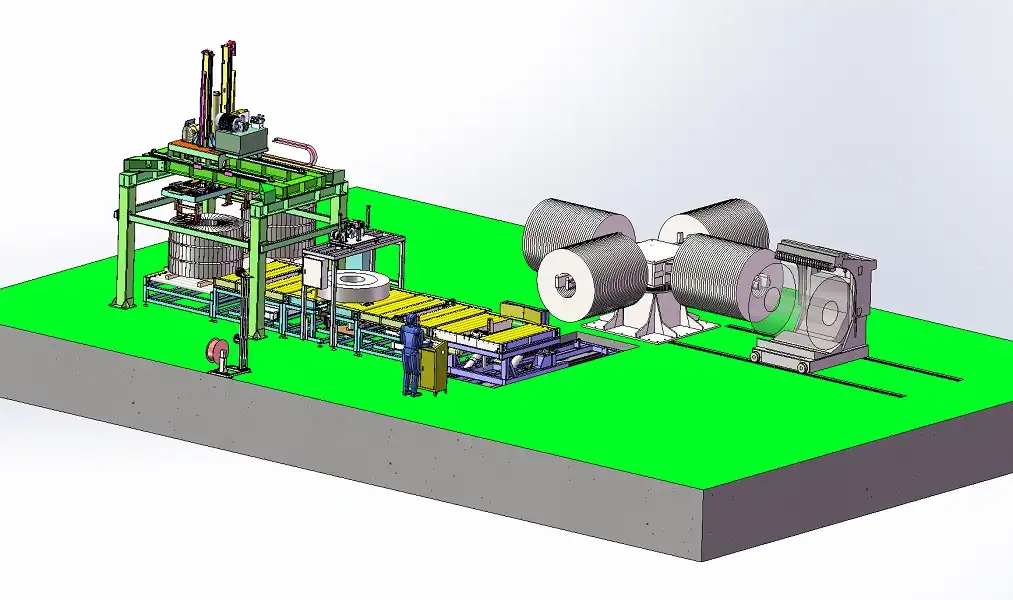

In today's competitive manufacturing environment, maximizing operational efficiency is paramount. For industries handling steel production, a critical factor is ensuring the smooth, uninterrupted operation of the steel coil packing line. A high-quality, well-maintained automated coil packing system directly boosts productivity, minimizes costly downtime, and enhances workplace safety. This guide explores the essential quality aspects that contribute to a flawlessly operating steel coil packing line, delivering optimal performance for your facility.

1. Understanding the Impact of Quality on Steel Coil Packing Lines

A steel coil packing line is an intricate system where numerous components must function in perfect harmony. The inherent quality of this equipment profoundly influences its operational efficiency, safety record, and overall lifespan. Systems constructed with subpar materials or inadequate engineering often suffer from frequent breakdowns, leading to escalating maintenance costs and potential hazards for workers. Therefore, selecting a system built with premium-grade materials, incorporating advanced automation technology, and backed by expert craftsmanship is essential for reliable steel coil packaging.

A strong commitment to quality throughout the design and manufacturing process ensures each component, from heavy-duty conveyors to precision strapping machines, is rigorously tested and built for durability. This focus optimizes the system for high performance, ensuring your steel coil handling and packing operations run smoothly and safely day after day.

2. Quality Assurance Pillars in Manufacturing Processes

The foundation of a reliable steel coil packing line lies in its manufacturing process. Achieving high quality starts during the initial design phase and continues meticulously through production, assembly, and final validation testing. Adherence to internationally recognized standards, such as those set by the International Organization for Standardization (ISO), combined with lean manufacturing principles, helps eliminate inefficiencies and ensures precision engineering.

Effective quality control involves multiple checkpoints:

- Inspection and verification of raw materials.

- Use of advanced technologies like Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machining for precise construction.

- Thorough testing of sub-assemblies and the final integrated system.

Furthermore, subjecting the system to extensive stress testing simulates demanding real-world operational conditions. This verifies the packing line's robustness and its ability to withstand the rigors of continuous, heavy-duty use, guaranteeing superior reliability and long-term performance in your steel coil strapping and packaging workflow.

3. Why Customization is Crucial for Optimal Performance

Every manufacturing facility has unique operational parameters and specific needs. A one-size-fits-all approach rarely delivers peak efficiency. Fully customizable steel coil packing solutions allow the system to be tailored precisely to your operational requirements. Whether needing specific safety interlocks, higher packing speeds for increased throughput, or seamless integration with existing plant management software, a collaborative design process ensures the final packing line meets your exact specifications.

Focusing on customization ensures the packing line not only operates flawlessly but actively enhances your overall production flow. Key customization options include:

- Strapping Configurations: Tailored based on steel coil dimensions (ID, OD, width) and weight.

- Automated Handling: Incorporating coil cars, turnstiles, and feeding systems to minimize manual labor and improve cycle times.

- Enhanced Safety Features: Implementing light curtains, safety fencing, automatic shutdowns, and clearly marked emergency stop controls.

- Energy Efficiency: Utilizing variable frequency drives (VFDs) and energy-saving components to reduce operational costs.

These tailored solutions result in a packing line that maximizes efficiency and throughput while minimizing potential downtime and long-term maintenance demands.

4. Proactive Maintenance: Key to Longevity and Performance

Even the most robustly built steel coil packing line requires consistent, proactive maintenance to sustain peak performance throughout its service life. Preventative maintenance is fundamental to avoiding unexpected equipment failures and the associated high costs of emergency repairs and production halts. A comprehensive maintenance program is integral to keeping your packing line running smoothly.

Essential routine maintenance tasks include:

- Lubrication: Regularly lubricating bearings, chains, and other moving parts reduces friction and prevents premature wear.

- Component Inspection: Periodically inspecting belts, chains, rollers, and conveyors for signs of wear, tension loss, or damage.

- Electrical System Checks: Verifying the integrity of wiring, connections, sensors, and control panels for proper function.

- Safety System Validation: Regularly testing sensors, emergency stops, and safety interlocks to ensure they operate correctly.

Providing detailed maintenance schedules and offering operator training empowers your team to perform essential upkeep between scheduled professional service visits. Adhering to these maintenance protocols significantly extends the packing line's lifespan, reduces unplanned downtime, and ensures continuous, reliable operation.

5. The Role of Technological Innovation in Modern Packing Lines

Innovation is a driving force behind improving quality and performance in steel coil packing lines. Continuous investment in research and development allows integration of cutting-edge technologies, preparing your packing line for the future and the demands of concepts like Industry 4.0. Technologies such as IoT-enabled sensors for remote monitoring and AI-driven predictive maintenance algorithms are transforming packing line capabilities.

Key benefits offered by these innovations include:

- Real-Time Performance Monitoring: Tracking key operational parameters and system diagnostics remotely.

- Predictive Maintenance Alerts: Advanced algorithms analyze sensor data to predict potential failures, allowing maintenance to be scheduled proactively before a breakdown occurs.

- Automated Process Adjustments: Systems can potentially adapt wrapping or strapping parameters automatically based on coil data, maintaining efficiency even with varying product specifications.

Embracing technological innovation not only enhances quality and reliability but also builds resilience, making your steel coil packing line more adaptable to evolving production requirements and ensuring its long-term value.

6. Importance of Comprehensive Support and Operator Training

A quality commitment extends beyond the initial installation. Ongoing technical support is crucial for ensuring your steel coil packing line consistently operates at its best. Access to expert assistance for troubleshooting, readily available spare parts, and remote diagnostic capabilities can significantly minimize disruption if issues arise.

Furthermore, comprehensive training programs are vital for equipping your operational and maintenance staff. Proper training ensures they can operate the machinery efficiently, understand its safety features, and perform basic maintenance tasks correctly. Effective training resources often include:

- Hands-on operational training during commissioning.

- Detailed operating and maintenance manuals.

- Video tutorials covering specific procedures or troubleshooting steps.

A well-trained team contributes significantly to smooth operations and equipment longevity. Providing robust support and training ensures you have the resources needed to maintain optimal performance of your steel coil packing line.

7. Key Business Outcomes of a High-Quality Packing Line

Investing in a high-quality steel coil packing line translates directly into tangible business results. A system that operates reliably with minimal downtime fosters higher productivity, lowers operational expenditures, and contributes to a safer working environment.

Key benefits driven by a quality-focused packing line include:

- Increased Throughput: Minimizing bottlenecks and ensuring smooth, automated coil handling allows the line to process more steel coils per shift.

- Reduced Labor Costs: Automation in feeding, strapping, wrapping, and weighing reduces the need for manual intervention, allowing personnel to focus on higher-value tasks.

- Enhanced Product Protection: Consistent and secure packaging protects valuable steel coils from damage during handling, transit, and storage, reducing material waste and potential customer claims.

- Improved Workplace Safety: Integrated safety features, proper guarding, and well-trained operators significantly reduce the risk of workplace injuries, lowering liability and fostering a safer culture.

Ultimately, selecting a high-quality steel coil packing line represents a strategic investment in your company's operational efficiency and long-term profitability.

Conclusion

The core principle for achieving flawless steel coil packing line operation is an unwavering focus on quality across the entire lifecycle – from initial design and robust manufacturing to proactive maintenance and comprehensive support. By prioritizing durable construction, customization for specific needs, technological innovation, and thorough operator training, manufacturers can ensure their packing lines meet the highest standards of performance and reliability. Choosing packing solutions built on these quality foundations provides not just machinery, but a dependable system engineered for efficiency and contributing positively to your business's success.

Get Your Best Solution !