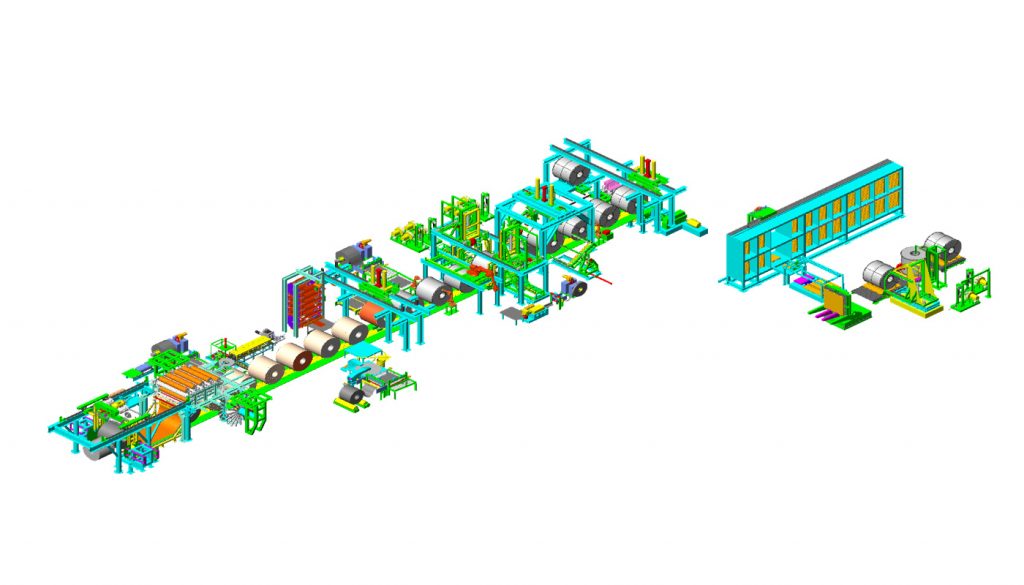

In the world of heavy industry, where precision, durability, and efficiency reign supreme, steel coil packing lines represent the backbone of supply chain success. Every project is unique, reflecting the distinct challenges and opportunities presented by the industries we serve. Our journey in delivering top-tier steel coil packing line solutions has been one of innovation, dedication, and exceeding expectations.

In the world of heavy industry, where precision, durability, and efficiency reign supreme, steel coil packing lines represent the backbone of supply chain success. Every project is unique, reflecting the distinct challenges and opportunities presented by the industries we serve. Our journey in delivering top-tier steel coil packing line solutions has been one of innovation, dedication, and exceeding expectations.

Each milestone achieved showcases not only our technical expertise but also our commitment to understanding and addressing the intricate needs of our clients. Let’s delve into how we’ve turned ambitious visions into tangible results, earning trust and recognition across diverse sectors.

Steel coil packing systems are more than just machines; they are the heartbeat of operational efficiency in industries that demand reliability and speed. Success in these projects is not just about delivering hardware—it’s about enabling transformative results. Our track record demonstrates how thoughtful design and customer-centric strategies can elevate businesses, helping them achieve long-term gains in quality, cost efficiency, and safety.

When evaluating project success, it’s critical to analyze every phase, from initial design to post-installation support. This ensures not only technical excellence but also alignment with the evolving needs of each operation. Let’s explore the hallmarks of our successful projects, diving into the nuances that set us apart.

[claim]

Our experience in delivering successful steel coil packing line projects stems from understanding the delicate balance between technical innovation and real-world application, ensuring every solution is customized to exceed expectations.

1. How Do We Tailor Steel Coil Packing Lines to Client Needs?

1.1 Defining the Client’s Vision

Every project starts with understanding the client’s operational goals and challenges. By conducting in-depth consultations, we gain insights into the unique demands of their industry. Are they seeking to maximize throughput, enhance safety protocols, or integrate automation to reduce manual labor? Each answer informs the foundation of the project.

The cornerstone of our approach lies in collaboration. We listen, ask probing questions, and dig deep into operational nuances. This stage transforms abstract goals into a defined roadmap. It’s not just about meeting current needs but also planning for future scalability.

1.2 Incorporating Industry-Specific Requirements

No two industries have identical priorities, and steel coil packaging requirements can vary significantly. For example, steel mills prioritize durability under extreme conditions, while coil slitting centers focus on agility and precision. Our expertise lies in identifying these subtle differences and integrating solutions tailored to meet these specific demands.

Drawing from years of experience, we implement design elements that address common pain points. Whether it’s ensuring compatibility with high-speed production lines or accommodating varying coil sizes, our systems are designed with precision to align with industry benchmarks.

1.3 Precision Engineering for Seamless Integration

Integration isn’t just about plugging a machine into an existing workflow; it’s about designing a system that enhances every stage of the production cycle. From layout optimization to software customization, every detail is scrutinized.

By leveraging advanced engineering tools, we model operational environments to anticipate challenges and opportunities. This reduces downtime during implementation and ensures long-term reliability. Our commitment to seamless integration has consistently led to high client satisfaction rates.

2. What Challenges Do Steel Coil Packing Line Projects Address?

2.1 Streamlining Production Workflow

Efficiency is the backbone of any steel coil packing line project. A well-designed system eliminates bottlenecks, enhances throughput, and ensures consistent performance. But achieving these results requires addressing workflow gaps.

Our team begins by mapping the existing production cycle to identify inefficiencies. Then, we implement targeted solutions, such as automated conveyor systems and advanced packaging techniques, to minimize delays. Each upgrade is aimed at creating a streamlined process that boosts output without compromising quality.

2.2 Ensuring Operational Safety Standards

Safety is a non-negotiable aspect of every project. Steel coils are heavy, and the risks of improper handling are significant. Our designs incorporate features that minimize risks, such as automated coil positioning, safety guards, and ergonomic controls.

Regulatory compliance is another crucial element. By adhering to international safety standards, our systems not only protect workers but also enhance the reputation of client operations. This dual focus on safety and compliance is one of the reasons our solutions are trusted globally.

2.3 Reducing Long-Term Maintenance Burdens

Maintenance costs can significantly impact the ROI of any industrial equipment. From day one, we design our systems with durability and low maintenance in mind. Components are selected for their longevity, while maintenance routines are simplified to reduce downtime.

Clients often cite this aspect as a key driver of satisfaction, as it leads to fewer disruptions and lower operational costs. Predictive maintenance features further enhance reliability, allowing issues to be addressed before they escalate.

3. How Do Our Projects Align with Future Industry Trends?

3.1 Embracing Automation for Maximum Efficiency

The industrial landscape is increasingly shifting toward automation, and steel coil packing lines are no exception. By integrating cutting-edge automation technologies, our projects help clients stay ahead of the curve. Automation eliminates human error, improves consistency, and significantly boosts production speed.

Our systems leverage programmable logic controllers (PLCs) and industrial IoT (IIoT) technologies to create intelligent operations. Real-time data monitoring enables instant adjustments, ensuring peak performance even under fluctuating demand. Clients often note how these features prepare them for long-term industry advancements.

3.2 Sustainability and Energy Efficiency

Sustainability is no longer optional—it’s a requirement. Modern steel coil packing systems must minimize environmental impact while maximizing efficiency. Our designs incorporate energy-efficient motors, reduced waste handling, and eco-friendly packaging materials to align with green initiatives.

This dual focus on sustainability and efficiency not only reduces operational costs but also meets the growing expectations of environmentally conscious stakeholders. It’s a win-win approach that strengthens both bottom-line and brand reputation.

3.3 Customization for Scalability

Future-proofing is a critical consideration in every project we undertake. Industries evolve, and so must their operational tools. By designing customizable solutions, we ensure that our clients can scale their systems as their needs grow.

From modular designs to software updates, our systems are built to adapt. This ensures that our clients remain competitive even as industry demands change. Scalability is not just about hardware; it’s about creating a system that evolves seamlessly with the business.

4. Why Is Client Collaboration the Key to Success?

4.1 Building Strong Relationships

Every successful project begins with trust. We prioritize building relationships with our clients, fostering open communication, and encouraging active participation throughout the project lifecycle. This collaborative approach ensures that the final product aligns perfectly with the client’s vision.

Clients often remark on the value of being involved in the process. From initial consultations to post-installation support, their feedback shapes the system’s design, ensuring it meets both technical and operational expectations.

4.2 Transparent Processes and Real-Time Updates

Clear communication is at the heart of our project management philosophy. By providing clients with regular updates and progress reports, we eliminate uncertainty and build confidence. This transparency extends to addressing challenges, ensuring swift resolutions without compromising the timeline.

Clients appreciate our proactive approach, as it fosters a sense of partnership rather than a transactional relationship. When clients feel involved, they are more invested in the project’s success.

4.3 Post-Installation Support and Training

Delivering a successful steel coil packing line project doesn’t end with installation. Comprehensive post-installation support is critical for ensuring long-term success. Our team provides hands-on training for operators, detailed maintenance manuals, and round-the-clock technical assistance.

This support framework reduces downtime and empowers clients to maximize their system’s potential. Many clients highlight this ongoing partnership as a key differentiator, setting our services apart from competitors.

Conclusion

Steel coil packing lines are integral to the success of heavy industries, and delivering effective solutions requires more than just technical expertise. It demands a holistic approach that balances cutting-edge technology, safety, and client collaboration.

[claim]

Our proven track record stems from a commitment to innovation, sustainability, and long-term partnerships. Each project is a testament to our ability to turn challenges into opportunities, creating systems that drive operational excellence and future-proof our clients’ businesses.

By focusing on customization, safety, and sustainability, we ensure our solutions align not only with today’s demands but also with the evolving needs of tomorrow’s industries.

Get Your Best Solution !