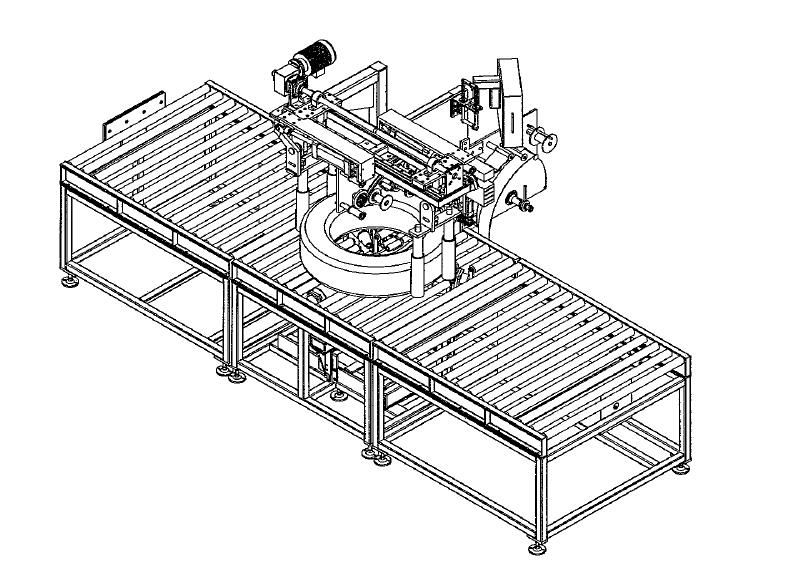

Coil wrapping machine in action.

From Packaging to Storage: Reducing the Risk of Damage in Steel Coil Handling

In the world of manufacturing and industrial processes, steel coils play a pivotal role. These massive rolls of steel are the lifeblood of numerous industries, from automotive to construction. However, the journey of a steel coil from production to final use is fraught with potential hazards. Mishandling at any stage can lead to significant damage, resulting in costly losses and production delays. In this comprehensive guide, we’ll explore the intricate process of steel coil handling, focusing on strategies to minimize damage from packaging to storage.

Understanding the Importance of Proper Steel Coil Handling

Before we dive into the specifics of damage prevention, it’s crucial to understand why proper handling of steel coils is so important. Steel coils are not just valuable in terms of raw material costs; they represent a significant investment in time, energy, and resources. A single damaged coil can disrupt entire production lines, leading to:

- Increased production costs

- Delays in manufacturing schedules

- Potential safety hazards for workers

- Reduced quality of final products

- Waste of valuable resources

With these high stakes in mind, let’s explore the journey of a steel coil and the key areas where damage prevention is critical.

The Steel Coil Journey: From Production to End-Use

1. Production and Initial Packaging

The journey begins at the steel mill, where molten steel is rolled into massive coils. Even at this early stage, proper handling is crucial. The initial packaging of steel coils typically involves:

- Applying protective oils or coatings

- Wrapping the coil in moisture-resistant materials

- Securing the coil with straps or bands

This initial protection is the first line of defense against damage and corrosion.

2. Transportation from Mill to Warehouse

The next critical phase is the transportation of steel coils from the mill to storage facilities or distribution centers. This stage presents numerous opportunities for damage if not handled correctly. Key considerations include:

- Proper loading techniques onto trucks or rail cars

- Secure fastening to prevent movement during transit

- Protection from the elements during outdoor transportation

3. Warehouse Reception and Unloading

Upon arrival at the warehouse, the unloading process presents another set of challenges. Warehouse staff must be trained in proper unloading techniques to prevent damage. This includes:

- Using appropriate lifting equipment

- Inspecting coils for any transit damage

- Properly documenting the condition of received coils

4. Storage in the Warehouse

Long-term storage of steel coils requires careful planning and execution. Proper warehouse storage involves:

- Climate-controlled environments to prevent rust and corrosion

- Appropriate racking systems designed for coil storage

- Regular inspections to detect any developing issues

5. Handling for Processing or Shipment

When it’s time for the coils to be processed or shipped to end-users, careful handling is once again crucial. This stage may involve:

- Repackaging for shipment

- Cutting or processing the coil for specific applications

- Loading onto vehicles for final delivery

Key Strategies for Damage Prevention in Steel Coil Handling

Now that we’ve outlined the journey of a steel coil, let’s delve into specific strategies for preventing damage at each stage.

Optimal Packaging Techniques

The foundation of damage prevention lies in proper packaging. Here are some best practices:

- Use high-quality wrapping materials: Invest in moisture-resistant, durable packaging materials that can withstand the rigors of transportation and storage.

- Apply edge protectors: The edges of steel coils are particularly vulnerable to damage. Using sturdy edge protectors can significantly reduce the risk of edge damage.

- Implement proper banding techniques: Ensure that bands are tight enough to secure the coil but not so tight that they cause deformation.

- Consider climate-specific packaging: For coils destined for high-humidity environments, consider additional moisture barriers or desiccants in the packaging.

Transportation Best Practices

Safely transporting steel coils requires attention to detail and proper equipment. Key considerations include:

- Use specialized vehicles: Trucks or rail cars designed specifically for coil transport offer the best protection.

- Implement proper loading techniques: Train staff in the correct methods for loading coils to prevent shifting during transit.

- Secure coils properly: Use appropriate tie-downs and chocks to keep coils stable during transportation.

- Plan routes carefully: Choose transportation routes that minimize exposure to harsh weather conditions or rough terrain.

Warehouse Storage Solutions

Proper storage is critical for maintaining the quality of steel coils. Consider the following:

- Invest in quality racking systems: Purpose-built coil storage racks can significantly reduce the risk of damage during storage.

- Implement climate control: Maintain appropriate temperature and humidity levels to prevent rust and corrosion.

- Develop a robust inventory management system: Regular stock rotation and inspections can help identify and address potential issues early.

- Train warehouse staff: Ensure all staff are trained in proper handling techniques and safety procedures specific to steel coil storage.

Handling Equipment and Techniques

The right equipment, used correctly, can make a world of difference in preventing damage. Key points include:

- Use appropriate lifting equipment: Invest in specialized coil lifters and cranes designed for safe handling of steel coils.

- Implement proper lifting techniques: Train operators in the correct methods for lifting and moving coils to prevent damage and ensure safety.

- Regularly maintain equipment: Keep all handling equipment in top condition to prevent accidents or damage due to equipment failure.

Quality Control and Inspection Processes

Regular inspections and quality control measures are essential for catching and preventing damage. Consider implementing:

- Incoming inspection procedures: Thoroughly inspect all coils upon arrival for any signs of damage or defects.

- Regular storage inspections: Conduct routine checks of stored coils to catch any developing issues.

- Pre-shipment inspections: Before coils leave the warehouse, perform a final check to ensure they’re in perfect condition.

Advanced Technologies in Steel Coil Handling

As technology advances, new tools and techniques are emerging to improve steel coil handling. Let’s explore some cutting-edge solutions:

Automated Handling Systems

Automation is revolutionizing steel coil handling. Automated systems can:

- Reduce human error in handling

- Increase efficiency in loading and unloading

- Provide more consistent and gentle handling of coils

While the initial investment can be significant, the long-term benefits in damage reduction and efficiency gains can be substantial.

IoT and Sensor Technology

The Internet of Things (IoT) and advanced sensor technology are finding applications in steel coil handling:

- Environmental monitoring: Sensors can track temperature, humidity, and other factors that could affect coil quality.

- Impact detection: Sensors attached to coils or handling equipment can detect and log any impacts or mishandling.

- Real-time tracking: GPS and RFID technology allow for precise tracking of coils throughout the supply chain.

Advanced Packaging Materials

Innovation in packaging materials is providing better protection for steel coils:

- Smart packaging: Materials that change color or provide other indicators when exposed to damaging conditions.

- Nano-coatings: Ultra-thin protective layers that offer superior corrosion resistance.

- Biodegradable options: Eco-friendly packaging solutions that provide protection while reducing environmental impact.

Training and Safety: The Human Factor in Damage Prevention

While technology and equipment play crucial roles, the human factor remains paramount in preventing damage to steel coils. Let’s explore the importance of training and safety measures:

Comprehensive Training Programs

Developing a robust training program for all staff involved in steel coil handling is essential. This should include:

- Initial training: Thorough onboarding for new employees covering all aspects of safe coil handling.

- Ongoing education: Regular refresher courses and updates on new techniques or equipment.

- Specialized training: Advanced courses for staff operating specific equipment or handling unique types of coils.

Creating a Culture of Safety and Care

Beyond formal training, fostering a workplace culture that prioritizes safety and care for materials is crucial. This can involve:

- Regular safety meetings: Discuss recent incidents or near-misses and brainstorm prevention strategies.

- Incentive programs: Reward employees for maintaining excellent safety records and preventing damage.

- Open communication: Encourage staff to report potential issues or suggest improvements in handling processes.

Environmental Considerations in Steel Coil Handling

In today’s eco-conscious world, it’s important to consider the environmental impact of steel coil handling practices. Here are some areas to focus on:

Sustainable Packaging Solutions

Explore ways to reduce the environmental footprint of coil packaging:

- Recyclable materials: Use packaging that can be easily recycled or repurposed.

- Reusable packaging: Implement systems for returning and reusing packaging materials.

- Minimal packaging: Strive to use the least amount of packaging necessary while still ensuring adequate protection.

Energy-Efficient Handling and Storage

Look for ways to reduce energy consumption in coil handling and storage:

- LED lighting in warehouses: Reduce energy use while improving visibility.

- Energy-efficient handling equipment: Invest in modern, energy-efficient forklifts and cranes.

- Optimal warehouse layout: Design storage areas to minimize unnecessary movement of coils.

Waste Reduction Strategies

Implement strategies to minimize waste throughout the handling process:

- Precise cutting techniques: Use advanced cutting technologies to reduce offcuts and waste.

- Recycling programs: Ensure all recyclable materials, including damaged packaging, are properly recycled.

- Lean inventory management: Maintain optimal stock levels to prevent deterioration of stored coils.

The Economic Impact of Effective Damage Prevention

Investing in proper steel coil handling isn’t just about preventing immediate losses; it has far-reaching economic implications:

Cost Savings

Effective damage prevention leads to significant cost savings:

- Reduced material losses: Fewer damaged coils mean less waste and replacement costs.

- Lower insurance premiums: A track record of careful handling can lead to reduced insurance costs.

- Decreased downtime: Preventing damage means less time lost to repairs or waiting for replacements.

Enhanced Customer Satisfaction

Delivering undamaged, high-quality steel coils consistently can significantly boost customer satisfaction:

- Improved reputation: Become known as a reliable supplier of pristine materials.

- Increased repeat business: Satisfied customers are more likely to place repeat orders.

- Positive word-of-mouth: Happy customers can become valuable advocates for your business.

Competitive Advantage

In a competitive market, superior handling practices can set you apart:

- Unique selling proposition: Promote your damage prevention record as a key differentiator.

- Higher-value contracts: The ability to consistently deliver undamaged coils can open doors to more lucrative contracts.

- Industry leadership: Become recognized as a leader in best practices for steel coil handling.

Future Trends in Steel Coil Handling

As we look to the future, several trends are emerging that will shape the landscape of steel coil handling:

AI and Machine Learning

Artificial Intelligence and Machine Learning are set to revolutionize steel coil handling:

- Predictive maintenance: AI can analyze data to predict when equipment is likely to fail, allowing for proactive maintenance.

- Optimized storage: Machine learning algorithms can determine the most efficient storage arrangements based on coil characteristics and usage patterns.

- Automated quality control: AI-powered visual inspection systems can detect defects or damage with incredible accuracy.

Blockchain for Supply Chain Transparency

Blockchain technology has the potential to transform supply chain management for steel coils:

- Immutable record-keeping: Create an unalterable record of each coil’s journey from production to end-use.

- Enhanced traceability: Quickly trace the origin and handling history of any coil in case of quality issues.

- Streamlined documentation: Reduce paperwork and increase efficiency in tracking and transferring ownership of coils.

Augmented Reality in Handling and Training

Augmented Reality (AR) is finding applications in both hands-on handling and staff training:

- Guided handling: AR headsets can provide real-time guidance to operators on proper handling techniques.

- Virtual training: Create immersive training experiences that simulate various handling scenarios without risk to actual materials.

- Remote assistance: Enable experts to provide guidance to on-site staff through AR interfaces.

Conclusion: A Holistic Approach to Steel Coil Protection

As we’ve explored throughout this comprehensive guide, protecting steel coils from damage requires a multifaceted approach. From the moment a coil is produced to its final use, every stage of handling, transportation, and storage presents both challenges and opportunities for damage prevention.

By implementing best practices in packaging, utilizing appropriate handling equipment, maintaining optimal storage conditions, and leveraging cutting-edge technologies, businesses can significantly reduce the risk of damage to their valuable steel coils. Moreover, investing in comprehensive training programs and fostering a culture of safety and care ensures that the human element in coil handling is as reliable as the equipment and processes.

As the industry continues to evolve, staying abreast of emerging trends and technologies will be crucial for maintaining a competitive edge. Whether it’s through the adoption of AI-driven handling systems, the implementation of blockchain for enhanced traceability, or the use of augmented reality in training, forward-thinking companies have numerous tools at their disposal to further refine their coil handling processes.

Ultimately, the goal is not just to prevent damage, but to optimize the entire lifecycle of steel coils. By doing so, businesses can realize significant cost savings, enhance customer satisfaction, and position themselves as leaders in their field. In the complex world of steel manufacturing and distribution, careful handling of these vital materials is more than just a best practice—it’s a key driver of success and sustainability.