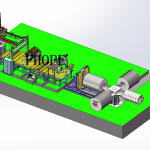

The Online Coil Stretch Wrapper is a specialized machine tailored for the efficient wrapping of metal coils in industrial settings, maintaining their integrity during storage and transportation. This machine is crucial for industries dealing with wire, steel strips, and other coil products. It operates in an online environment where coils can be wrapped continuously as they come off the production line. The machine incorporates a heavy-duty rotating mechanism for the coil, an automated stretch film applicator, and a synchronized cutting system. High adaptability allows it to handle coils of different sizes and weights with ease, ensuring a tight and secure wrap every time.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Fully Automatic Coil Stretch Wrapper

- Coil Diameter Compatibility: 600mm to 1600mm

- Coil Width Compatibility: Up to 1400mm

- Maximum Coil Weight: 20,000kg

- Wrapping Material Options: PE stretch film, PVC

- Film Roll Dimensions: Diameter up to 500mm; Width up to 750mm

- Operational Voltage: 480V, 60Hz, three-phase

- Machine Weight: Approximately 7500kg

- Wrapping Speed: Up to 60 RPM

- Machine Dimensions: Length: 6000mm; Width: 3500mm; Height: 4000mm

- Control System: Advanced PLC with touchscreen controls

- Customization: Adjustable settings for different coil dimensions

- Safety Features: Emergency stop, safety light curtains

- Efficiency Features: Integrated cutting mechanism, minimal film waste

Applications:

- In the steel manufacturing sector, precise and robust wrapping is necessary to prevent surface damage and corrosion during storage and overseas shipment. This coil stretch wrapper ensures that steel coils, up to 1600mm in diameter and weighing up to 20,000kg, are tightly wrapped with high-grade PE stretch film. This wrapping shields the coils from moisture and environmental contaminants, greatly reducing the risk of rust and ensuring that the product maintains its quality and structural integrity when reaching customers.

- For companies specializing in copper wire, the wrapper is adept at handling spools of wire efficiently, improving workflow by wrapping up to 60 coils per hour. The machine’s capacity to securely wrap coils with diameters ranging from 600mm to 1600mm minimizes handling damages and preserves the delicate surfaces of the copper wire. This automated process is vital for maintaining the electrical properties of the copper, ensuring optimal performance in end-user applications such as electrical wiring and telecommunications.

- In the aluminum industry, where quick and secure packaging is key to maintaining product quality, this machine offers a solution by wrapping coils swiftly, ensuring they are retail-ready soon after production. Aluminum coils handled by this stretch wrapper are prepared for extended stockpiling or direct shipment without the risk of oxidation or contamination. The reliable and consistent wrapping process not only preserves the aesthetic and functional quality of the aluminum but also optimizes supply chain operations by reducing packaging time and costs.