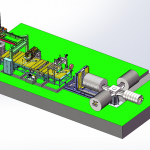

The simulation video shows the following packing steps:

1. Loading to the beffering area

2. Coil information checking with Level one systme

3. Automatic/manuall strapping

4. Coil wrapping with stretch film/paper

5. Circle paper/steel sheet covering. 6. OD strapping

7. Eye through strapping

8. Manually checking

9. Coil out feeding.

This Metal coil packaging system can be customized and designed per different layout requirement.

• Coils are typically aligned and centered using guide rails, aligning chains or aligning rolls before entering the packaging system. This ensures proper positioning for the wrapping and strapping stages.

• Coil parameters like inside and outside diameters, thickness and weight are measured using sensors to determine the correct packaging settings.

• Strapping machines can apply vertical, horizontal or diagonal straps using polyester or steel strapping material. Common strap tensions range from 300-1000 kg.

• Wrapping machines unroll stretch film or paper around the coil using rotating rolls or alternating film arms. They help contain smaller parts and prevent scratching of the coil surface.

• Circulating sheets of paper, cardboard or steel are used to protect the open ends of the coil from contamination and damage during transport.

• Additional OD straps help secure the end caps and provide further protection for the coil edges.

• Eye-through straps pass through the coil hole and are tightened. They constrain the coil and absorb vibrations during transport.

• Inspection stations manually check for flaws in the packaging like torn or loose film, improper positioning of protection sheets, etc. Defective packages are rejected.

• Coils are discharged onto conveyors or turntables aligned with outgoing trucks for efficient packaging. Line integration optimizes material flow.

• Customized systems may integrate additional functions like barcode labeling, rotation, sorting and logging of coil data.

More advanced systems offer high levels of automation, monitoring and integration with production lines for non-stop coil packaging.