The machine is able automatic feeding the OD protector and wrap it by stretch film. Two packing steps in one time.

A master coil wrapper with OD protector feeding is a type of packaging equipment designed to automatically feed and wrap steel coils with stretch film and OD protectors, in a single step. This machine is commonly used in manufacturing and logistics industries.

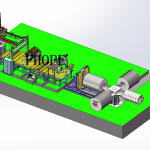

The master coil wrapper typically consists of a conveyor system, a wrapping station, and an OD protector feeding station. The process begins with the steel coil being loaded onto the conveyor system, which moves it to the wrapping station. At the wrapping station, the coil is automatically wrapped with stretch film, while at the same time, the OD protector is fed and applied to the coil in a single step.

One advantage of using a master coil wrapper with OD protector feeding is that it can improve the efficiency and consistency of the packaging process. By automating the packaging process, businesses can reduce the amount of time and labor required to package each coil manually. Additionally, the OD protector applied by the machine ensures that the coil is properly protected during storage and transportation, reducing the risk of damage and improving overall product quality.

The machine can be customized to handle different coil sizes and weights, as well as different types of stretch films and OD protectors. Some machines may offer additional features, such as automatic coil loading, adjustable wrapping tension, or automatic stacking of the wrapped coils.

Overall, a master coil wrapper with OD protector feeding can be a valuable investment for businesses that need to package steel coils on a regular basis. By improving efficiency, reducing labor costs, and ensuring that each coil is properly protected, these machines can help to improve the overall productivity and profitability of the business.