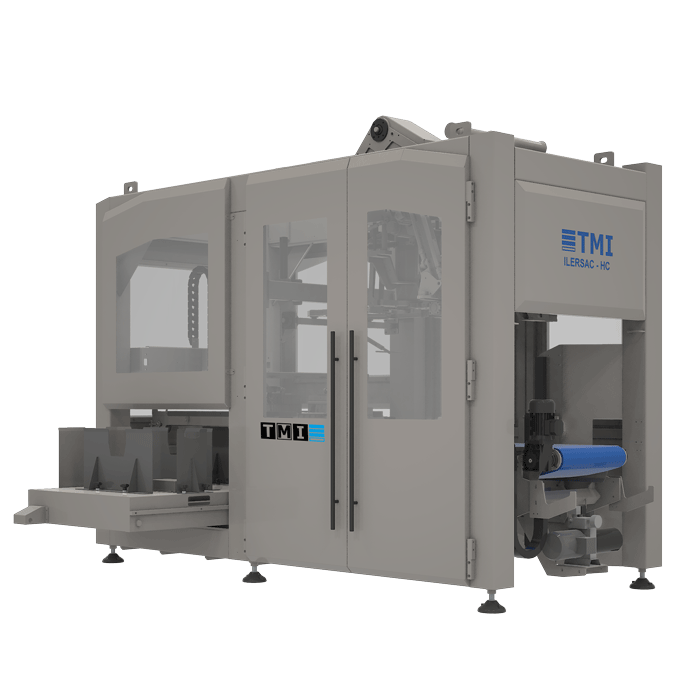

A hygienic automatic bagging machine is a type of packaging equipment that is designed to be sanitary and hygienic in its operation. These types of machines are often used in the food and pharmaceutical industries, where maintaining cleanliness and preventing contamination is of the utmost importance.

Bag feeding system:

• Feeds empty bags from a roll or stack into the bag opening mechanism

• Ensures a continuous supply of bags for high throughput

Bag opening mechanism:

• Uses vacuum cups, clamps or guides to securely open the bag

• Holds the bag in position ready to receive products

Product feeding system:

• Automatically feeds products such as food items, powders or liquids into the open bags

• Uses conveyors, chutes, nozzles, etc. depending on the product type

Bag sealing system:

• Seals the bag securely after the products are inside

• Uses techniques like heat sealing, tying or clipping depending on the bag material

Control system:

• A PLC controls the coordinated movements and functions of the various components

• Ensures a hygienic operation by preventing product build-up or residue

Hygienic design features:

• Smooth surfaces that can be easily cleaned

• Sealable joints between components

• Double airlocks to prevent cross-contamination between zones

• Use of FDA-compliant materials that can withstand sanitation chemicals

• Easy draining to facilitate flushing and cleaning in place (CIP)

There are several features that contribute to the hygienic design of an automatic bagging machine. These may include:

- Stainless steel construction: Stainless steel is a durable and easy-to-clean material that is resistant to corrosion and bacteria.

- Smooth surfaces and crevice-free design: A smooth surface and a lack of crevices can help to prevent the accumulation of dirt and bacteria, making the machine easier to clean and maintain.

- Sealed bearings and motors: Sealed bearings and motors help to prevent the ingress of dirt, dust, and other contaminants, which can contribute to the overall cleanliness of the machine.

- Automatic cleaning systems: Some automatic bagging machines may include automatic cleaning systems, such as high-pressure water jets or air knives, which can help to keep the machine clean and hygienic during operation.

Overall, a hygienic automatic bagging machine is an important piece of equipment for businesses that need to maintain high levels of cleanliness and hygiene in their packaging operations.