When we first approached the idea of providing a turnkey steel coil packing solution for a leading steel manufacturer, we knew it wouldn’t be a one-size-fits-all process. Every step required meticulous planning, custom engineering, and an unwavering commitment to solving their unique challenges. The steel industry is unforgiving when it comes to efficiency and reliability, so we had to innovate, adapt, and deliver.

We weren’t just selling equipment; we were crafting a system that would define their operations for years to come. Our mission? To optimize their packing process, reduce downtime, and ensure every steel coil left their facility in perfect condition for shipping.

This was not just another project—it was a partnership, one that demanded collaboration across multiple teams to meet ambitious goals.

The final solution didn’t just meet their expectations—it exceeded them.

We began this journey by understanding the manufacturer’s pain points. Their existing packing process was labor-intensive, prone to inconsistencies, and resulted in high operational costs. They needed a system that could streamline operations, enhance product safety, and align with their growing production demands.

Our team conducted a thorough on-site analysis, gathering insights on their workflows, equipment limitations, and operational bottlenecks. We knew our solution had to tackle all these issues while delivering measurable results.

Through extensive collaboration, we were able to design and implement a packing solution tailored to their specific needs, transforming their operations and setting them up for long-term success.

1. What Were the Initial Challenges in Implementing the Packing Solution?

1.1 Understanding the Scope of the Problem

When we first engaged with the manufacturer, their primary concern was inefficiency. Their previous packing process relied heavily on manual labor, which introduced variability and slowed production cycles. In addition, the packaging materials they were using often failed to protect their coils adequately during transport, leading to customer complaints.

We realized early on that these issues weren’t isolated—they were deeply interconnected. Addressing one meant tackling the others head-on. This required a holistic solution, not just incremental improvements.

1.2 Identifying Operational Bottlenecks

Our on-site analysis revealed specific pain points that were costing the manufacturer time and money. For instance, manual handling of steel coils not only slowed operations but also introduced risks of injury. The lack of automation in the packing process resulted in inconsistent wrapping, which sometimes led to damaged coils during transit.

These inefficiencies compounded over time, creating a ripple effect that affected their ability to meet tight shipping deadlines and maintain client satisfaction.

1.3 Creating a Strategy to Overcome These Challenges

To address these challenges, we needed a strategy that combined advanced technology with practical engineering. This meant developing a packing line that could:

- Automate critical steps in the process

- Use high-quality materials for consistent protection

- Operate seamlessly with minimal downtime

- Scale with the manufacturer’s future growth needs

Our strategy wasn’t just about building a system—it was about building a better way to work.

2. How Did We Design a Custom Packing Line to Address the Manufacturer’s Needs?

2.1 Designing for Scalability

One of the manufacturer’s key concerns was future growth. While their current production volume was significant, they anticipated increasing demand in the coming years. Any solution we provided had to accommodate this growth without requiring a complete overhaul.

To achieve this, we focused on modular design principles. Each component of the packing line was engineered to be easily upgraded or expanded, ensuring long-term value and flexibility.

2.2 Incorporating Custom Features

The standard solutions on the market couldn’t address their unique requirements. For example, their steel coils came in various sizes, and the packing line had to adapt to each with precision. Additionally, they needed a system that could handle specific environmental conditions, such as extreme temperatures and high humidity levels, without compromising performance.

2.3 Testing and Prototyping

Before implementing the final system, we developed prototypes to test key features. This iterative process allowed us to refine the design, ensuring every component met the manufacturer’s needs. By involving their team in these tests, we also ensured that the solution aligned with their operational workflows.

Our focus on customization didn’t just solve their current problems—it laid the foundation for a more efficient, scalable, and reliable packing process.

3. What Technologies Did We Integrate to Enhance the Solution?

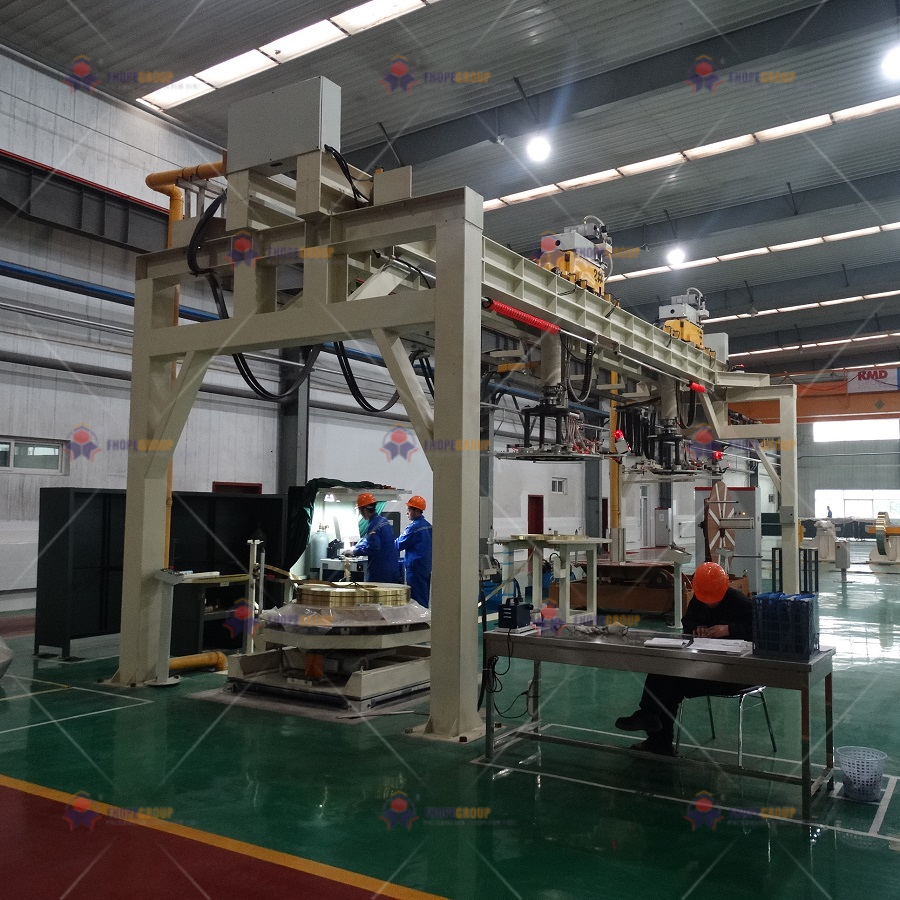

3.1 Leveraging Automation for Efficiency

Automation was the cornerstone of our solution. We introduced robotic arms for handling the steel coils, reducing manual intervention. These arms were programmed to handle coils of varying sizes with precision, ensuring that the wrapping process was consistent across all products.

The automated conveyors were designed to seamlessly transfer coils between stations, minimizing delays and ensuring a steady production flow. This approach not only improved efficiency but also significantly reduced the risk of workplace injuries.

3.2 Integrating Smart Sensors

We incorporated smart sensors throughout the packing line to monitor the process in real time. These sensors provided data on coil dimensions, wrapping tension, and material usage, allowing for immediate adjustments when needed.

This level of precision ensured that every steel coil was wrapped securely, reducing damage during transportation. Additionally, the sensors helped optimize material consumption, leading to cost savings over time.

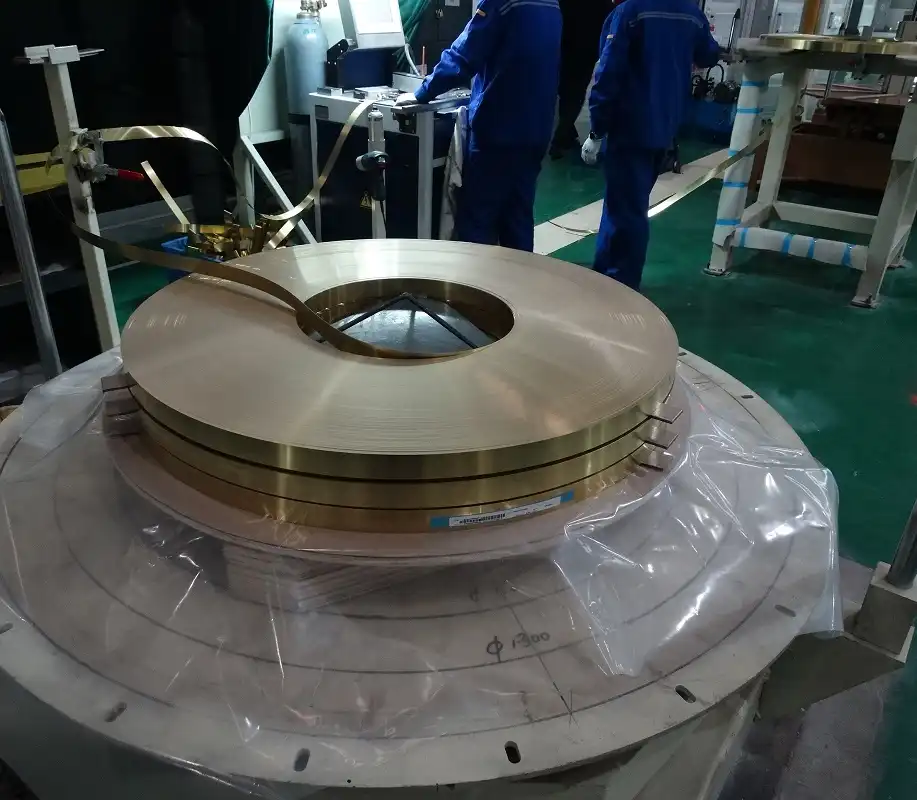

3.3 Using Advanced Wrapping Materials

The durability of the packaging was another critical aspect of our solution. We collaborated with material suppliers to source high-strength, weather-resistant wrapping materials. These materials were tested under various conditions to ensure they could withstand the rigors of transportation.

By integrating these technologies, we created a system that not only met but exceeded the manufacturer’s quality and efficiency standards.

4. How Did the Implementation Process Unfold?

4.1 Setting Up the Packing Line

The implementation process began with careful planning. We worked closely with the manufacturer’s operations team to minimize disruptions during the installation phase. The modular nature of our design allowed us to install and test individual components without halting production entirely.

Our team provided detailed timelines and progress updates, ensuring that all stakeholders were informed at every step of the process.

4.2 Training the Staff

A critical part of the implementation was training the staff to operate and maintain the new system. We conducted hands-on workshops and provided user-friendly manuals to ensure they felt confident using the technology.

This collaborative approach not only improved adoption rates but also helped the staff identify opportunities for further optimization.

4.3 Delivering Results

The results spoke for themselves. Within weeks of implementation, the manufacturer reported a significant reduction in packing time and material waste. Customer complaints about damaged coils dropped to nearly zero, and their overall operational costs decreased by 20%.

By delivering a seamless implementation, we proved that the right solution could transform not just a process but an entire operation.

Conclusion

The claim we set out to prove was simple yet ambitious: delivering a turnkey steel coil packing solution requires more than technical expertise—it demands a deep understanding of the client’s unique needs and challenges.

Through innovative design, advanced technologies, and seamless collaboration, we were able to help a leading steel manufacturer revolutionize their packing process. The result wasn’t just a system that worked but one that empowered them to scale their operations, reduce costs, and deliver unmatched quality to their customers.

This project reaffirmed our belief that true success lies in partnership. By listening, adapting, and innovating together, we turned a complex challenge into a powerful solution—one that will drive value for years to come.

Get Your Best Solution !