Comprehensive Guide: Reading RS232 Data from Packing Line Sensors on Your PC

In modern automated packing lines, efficiency and accuracy are paramount. Equipment like weighing sensors play a crucial role by ensuring products meet precise weight specifications. However, accessing the data generated by these sensors often presents a challenge. Many sensors output data via the RS232 serial communication protocol, but contemporary PCs rarely include native serial ports. This discrepancy complicates data acquisition, making it difficult to monitor weights, log data for quality control, or integrate sensor readings into larger production systems.

This comprehensive guide provides clear, step-by-step instructions on how to successfully read RS232 serial data from packing line equipment (like weighing sensors) using a standard Windows PC, enabling seamless data integration and analysis.

1. Essential Hardware Setup

Connecting your RS232 device to a modern PC requires specific hardware.

1.1. USB-to-RS232 Converter

Since most modern computers lack built-in RS232 ports, a USB-to-RS232 converter cable is necessary.

- Selection: Choose a reliable converter. Converters based on chipsets like FTDI or Prolific (ensure genuine chips) are generally known for better compatibility and stability across different operating systems. Check compatibility with your Windows version.

- Purpose: This cable acts as an adapter, allowing the serial signals from your sensor to be understood by your computer's USB port.

1.2. Physical Connection

- Connect the RS232 end of the converter cable to the corresponding RS232 port on your weighing sensor or packing line equipment.

- Plug the USB end of the converter cable into an available USB port on your Windows PC.

2. Driver Installation and Verification

Most USB-to-RS232 converters require drivers to function correctly.

- Installation: Install the drivers provided by the converter's manufacturer. These may come on a CD, but it's usually best to download the latest version from the manufacturer's official website to ensure compatibility and performance. Follow the installation instructions carefully.

- Verification:

- After installing the drivers and plugging in the converter, open Device Manager in Windows (you can search for it in the Start menu).

- Expand the Ports (COM & LPT) section.

- You should see a newly added COM port listed (e.g., "USB Serial Port (COM3)").

- Note down the assigned COM port number (e.g., COM3), as you will need it for software configuration. If you don't see a new port, check the driver installation or try a different USB port.

3. Configuring Serial Port Communication Parameters

For successful communication, the settings on your PC must exactly match the settings used by the RS232 device (e.g., the weighing sensor).

- Find the Parameters: Consult the technical manual or documentation for your specific weighing sensor or equipment. Look for the section detailing RS232 or serial communication settings. If unsure, contact the equipment manufacturer.

- Key Parameters: You need to identify the following:

- Baud Rate: The speed of data transmission (bits per second). Common values include 9600, 19200, 38400, 57600, 115200. Both devices must use the same rate.

- Data Bits: The number of bits in each data character. Usually 7 or 8. 8 is most common.

- Parity: A simple error-checking method. Options are None, Even, Odd, Mark, or Space. None is very common.

- Stop Bits: Bits sent at the end of a character to signal its completion. Usually 1 or 2. 1 is most common.

- Flow Control: Manages data flow to prevent buffer overruns. Options include None, XON/XOFF (software), RTS/CTS (hardware). None is often sufficient for simple sensor readings.

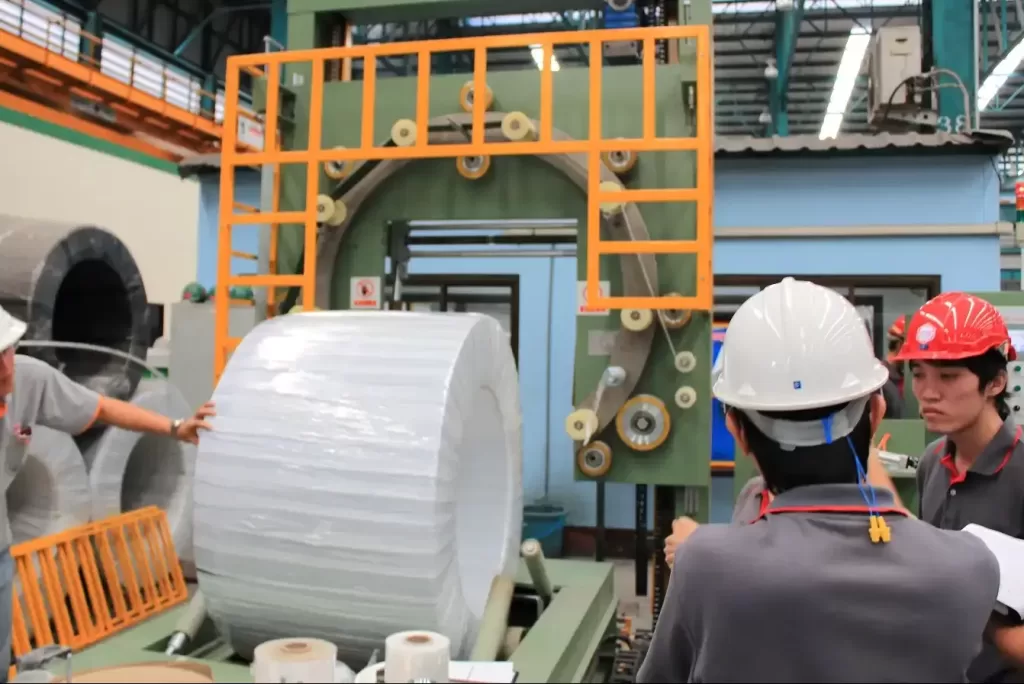

steel wire wrapping machine2 4. Using Terminal Software to Read and Monitor Data

Serial terminal emulator software allows you to connect to the COM port and view the incoming data stream. Several free and effective options are available:

4.1. PuTTY

A popular, free, and lightweight terminal emulator.

- Download PuTTY from its official website. No installation is required for the standalone executable.

- Run PuTTY.

- Under "Session" settings:

- Select Connection type: Serial.

- In "Serial line", enter the COM port number you noted (e.g.,

COM3). - In "Speed", enter the correct Baud Rate.

- Navigate to Connection -> Serial in the left-hand category tree.

- Configure the Data bits, Stop bits, Parity, and Flow control to match your sensor's specifications.

- Click Open. A terminal window will appear. If the connection and parameters are correct, you should see data streaming from your RS232 device.

4.2. Tera Term

Another powerful, free, open-source terminal emulator.

- Download and install Tera Term from its official source.

- Launch Tera Term.

- In the "Tera Term: New connection" dialog:

- Select the Serial option.

- Choose your COM port from the dropdown list.

- Click OK.

- Go to Setup -> Serial port...

- Configure the Baud rate, Data, Parity, Stop, and Flow control settings to match your device.

- Click OK. The terminal window will display incoming data if the setup is correct.

4.3. Other Software Options

Tools like RealTerm or Serial Port Monitor offer more advanced features, such as data logging to files, timestamping, and hexadecimal viewing, which can be useful for debugging or specific data capture needs.

5. Reading Data Programmatically (Optional Advanced Method)

For automated data logging, real-time processing, or integration into custom applications, you can use programming languages. This requires coding knowledge.

5.1. Using Python

Python's pySerial library is excellent for serial communication.

- Install library: Open Command Prompt or PowerShell and run:

pip install pyserial -

Basic Python Script:

import serial import time # Configure serial port (use your COM port and settings) ser = serial.Serial('COM3', 9600, parity=serial.PARITY_NONE, stopbits=serial.STOPBITS_ONE, bytesize=serial.EIGHTBITS, timeout=1) print(f"Connected to {ser.portstr}") try: while True: # Read one line of data, decode from bytes to string, remove trailing whitespace line = ser.readline().decode('utf-8', errors='ignore').rstrip() if line: print(f"Received: {line}") # Optional: Add a small delay if needed # time.sleep(0.1) except KeyboardInterrupt: print("Exiting program.") except serial.SerialException as e: print(f"Serial error: {e}") finally: if ser.is_open: ser.close() print("Serial port closed.")Remember to replace

'COM3'and9600with your actual COM port and baud rate.

5.2. Using C

The .NET framework provides the System.IO.Ports.SerialPort class.

- Add the necessary namespace:

using System.IO.Ports; - Create and configure a

SerialPortobject, setting properties likePortName,BaudRate,Parity,DataBits,StopBits. - Use the

DataReceivedevent handler or methods likeReadLine()orRead()within a loop to process incoming data. (Refer to Microsoft documentation for detailed examples).

6. Troubleshooting Common Issues and Best Practices

- Check Physical Connections: Ensure the cables are securely plugged in at both ends. Verify you are using the correct type of serial cable (straight-through vs. null modem - usually straight-through for device-to-PC).

- Verify COM Port Settings: Double-check that the Baud Rate, Data Bits, Parity, and Stop Bits in your software exactly match the device's requirements. Even a small mismatch will result in garbled data or no data.

- Driver Problems: Ensure the correct driver for your USB-to-RS232 converter and Windows version is installed. Check Device Manager for errors (yellow exclamation marks). Try reinstalling the driver or downloading the latest version.

- Port Conflicts: Make sure no other software is currently using the same COM port. Close any other terminal programs or applications that might be accessing it.

- Permissions: Sometimes, you may need to run your terminal software or custom application with administrator privileges to access hardware ports.

- Data Format Issues: The raw data received might be in ASCII text, hexadecimal, or a custom binary format. Consult the device manual to understand how to parse the data correctly (e.g., looking for specific start/end characters, checksums).

- Device Power: Ensure the RS232 device (e.g., weighing sensor) is powered on and functioning correctly.

horizontal steel coil packing machine2 7. Verifying the Connection: The Loopback Test

Before connecting to your sensor, you can test your PC's serial port configuration and the converter cable using a loopback test.

- Procedure: Disconnect the converter from the sensor. Use a small wire or paperclip to carefully connect the Transmit (TXD) pin to the Receive (RXD) pin on the RS232 end of the converter cable. (For a standard DB9 connector, this is usually pin 2 to pin 3).

- Testing: Open your terminal software (like PuTTY) configured for the COM port. Anything you type into the terminal should immediately appear back on the screen (echoed).

- Result: If the loopback test works, your PC, converter cable, drivers, and software settings are likely configured correctly. If it fails, recheck drivers, port settings, or the converter itself.

By following these steps systematically, you can reliably establish communication between your packing line's RS232 devices and your PC. Accessing this data enables real-time monitoring for quality assurance, provides valuable logs for analysis, and opens possibilities for optimizing your production processes. Always refer to your equipment's documentation as the primary source for specific communication protocols and parameters. If challenges persist, consulting technical support from the equipment or converter manufacturer can provide further assistance.

Get Your Best Solution !