How to Evaluate Coil Upender Suppliers: Key Factors to Consider

- How to Evaluate Coil Upender Suppliers: Key Factors to Consider

- 1. Industry Reputation and Experience

- 2. Product Range and Customization Options

- 3. Quality of Manufacturing and Materials

- 4. Technical Support and After-Sales Service

- 5. Cost vs. Value: Balancing Price and Long-Term Benefits

- 6. Lead Time and Delivery Capabilities

- 7. Safety Features and Compliance with Industry Standards

- 8. Customer Training and Installation Support

- Conclusion

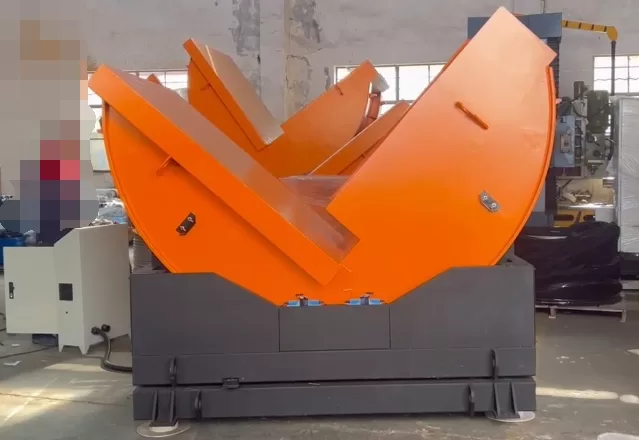

Selecting the right coil upender supplier is crucial for ensuring smooth operations, maximizing productivity, and improving safety in your facility. Coil upenders are essential machines in industries that handle heavy coils, such as steel and aluminum manufacturers. However, not all suppliers offer the same level of quality, support, and customization. Making the wrong choice can lead to inefficiencies, unexpected costs, and downtime.

In this guide, we’ll explore the key factors to consider when evaluating coil upender suppliers, so you can make an informed decision that will positively impact your business in the long run.

1. Industry Reputation and Experience

One of the first factors to evaluate is the supplier’s reputation and experience in the industry. How long has the supplier been in business? Do they specialize in coil upenders, or do they offer a broad range of products with limited focus on coil handling equipment?

A supplier with extensive experience in the coil handling industry is more likely to offer reliable, high-quality machines. They understand the specific challenges faced by businesses in this sector and have refined their products and services to meet these needs over time.

To assess the supplier’s reputation, consider:

- Customer reviews and testimonials: Are their past clients satisfied with the product and service?

- Case studies: Do they provide examples of how their machines have benefited other companies?

- Industry certifications: Are they recognized for meeting high manufacturing standards?

2. Product Range and Customization Options

Not all businesses require the same type of coil upender. Depending on your coil sizes, weights, and specific handling needs, you may require a customized solution. This is why it’s essential to evaluate the supplier’s product range and whether they offer customization options.

A good supplier will provide a range of coil upenders, including mechanical, hydraulic, and automatic models, each tailored for different operational requirements. More importantly, the ability to customize features such as load capacity, rotation speed, and safety mechanisms ensures the machine will be a perfect fit for your workflow.

Customization is particularly important for businesses that handle a variety of coil types or require specific operational efficiency. Ask the supplier:

- Can they adjust the size or design of the upender to accommodate your coils?

- Do they offer optional features, such as automation or advanced control systems?

3. Quality of Manufacturing and Materials

The quality of the materials and manufacturing process plays a significant role in determining the longevity and reliability of a coil upender. It’s essential to choose a supplier that prioritizes high-quality materials and uses precise engineering techniques to build durable machines.

You want to avoid a situation where the machine requires frequent repairs or replacements, which can lead to downtime and increased costs. Here are some considerations when evaluating manufacturing quality:

- Material Strength: Does the supplier use high-strength steel or other durable materials that can withstand the weight and pressure of heavy coils?

- Build Quality: Are the machines designed with precision to ensure smooth operation and minimal wear over time?

- Testing: Do the machines undergo rigorous testing before being shipped to ensure they meet industry standards for safety and performance?

Choosing a supplier that invests in top-quality manufacturing can prevent many operational headaches down the line.

Get Your Best Solution !

4. Technical Support and After-Sales Service

A coil upender is a significant investment, and you want to ensure that your supplier will support you long after the purchase. The availability of technical support and after-sales service is critical for the smooth operation of your coil upender. Even the best machines may need maintenance or troubleshooting over time, so it’s essential to evaluate the supplier’s commitment to after-sales service.

Ask potential suppliers about their support services:

- Do they offer 24/7 customer support?

- How quickly can they provide technical assistance if there’s a problem?

- Do they have a team of technicians available for on-site repairs and maintenance?

- What is their spare parts availability, and how long does it take to receive replacements?

Reliable technical support ensures that any issues with the machine can be resolved quickly, minimizing downtime and keeping your operations running smoothly.

5. Cost vs. Value: Balancing Price and Long-Term Benefits

While it’s tempting to choose the cheapest option, focusing solely on the upfront cost can lead to higher expenses in the long run. When evaluating coil upender suppliers, it’s important to balance price with the overall value they offer.

A supplier that provides a more expensive machine may include higher-quality materials, better customer service, and more advanced features, leading to a longer machine lifespan and fewer repairs. In contrast, a lower-cost machine might save you money initially but could result in increased maintenance and downtime costs.

When comparing costs, consider:

- Warranty periods: Does the supplier offer a comprehensive warranty that covers key components for an extended period?

- Included services: Does the price include installation, training, and routine maintenance, or are these additional costs?

- Energy efficiency: Is the machine designed to operate efficiently, reducing operational costs over time?

By focusing on the long-term benefits of quality and service, you can ensure a better return on investment (ROI) for your business.

6. Lead Time and Delivery Capabilities

Another key factor in evaluating a coil upender supplier is their lead time and delivery capabilities. If your business is in urgent need of a coil upender to keep production running smoothly, waiting for months to receive the equipment could cause significant disruptions.

When discussing lead times, ask the supplier:

- How long will it take to manufacture and deliver the machine?

- Do they have stock available, or are all machines made to order?

- Can they provide tracking information and updates throughout the shipping process?

A supplier that can deliver on time and provide accurate updates helps ensure your operations aren’t delayed due to a lack of equipment.

7. Safety Features and Compliance with Industry Standards

Handling heavy coils presents safety risks, and selecting a supplier that offers machines equipped with safety features is critical. A reputable supplier should prioritize safety and design their machines to comply with industry standards such as OSHA regulations.

Key safety features to look for in a coil upender include:

- Emergency stop buttons: These allow operators to halt the machine immediately if an issue arises.

- Load sensors: These detect when the machine is overloaded and automatically stop operations to prevent accidents.

- Safety locks: These secure the coil during rotation, preventing it from slipping or falling.

Additionally, check whether the supplier’s machines have been certified to meet safety and quality standards, such as ISO certifications.

8. Customer Training and Installation Support

Installing and operating a coil upender requires specific knowledge and expertise. To ensure a smooth transition and optimal use of the equipment, you’ll want to choose a supplier that offers customer training and installation support.

Good suppliers will provide on-site installation services to ensure the machine is set up correctly and integrated into your production line. Moreover, they should offer thorough training for your staff to ensure they can safely and efficiently operate the upender.

When evaluating suppliers, ask:

- Do they offer comprehensive training programs for operators and maintenance personnel?

- Will they provide on-site installation assistance and ensure that everything is functioning correctly before leaving?

- Do they offer training documentation or video tutorials for future reference?

Proper installation and training will ensure that you can get the most out of your investment from day one.

Conclusion

Evaluating coil upender suppliers involves more than just comparing prices. A high-quality supplier will offer durable, reliable machines that meet your specific operational needs, provide exceptional after-sales support, and prioritize safety and compliance. By considering factors such as industry reputation, product range, manufacturing quality, technical support, and value for money, you can ensure that you’re making a sound investment for your business.

Choosing the right supplier can mean the difference between smooth, efficient operations and costly downtime, so take the time to thoroughly vet your options. By focusing on long-term value, you can build a strong partnership with a supplier that will support your business for years to come.

Get Your Best Solution !