HOW TO DO VISUAL MANGEMENT FOR THE COIL PACKING LINE

Table of Contents

The FHOPE team rigorously adheres to various international and national standards for safety and efficiency in their coil packing line production, aligning with ANSI/ASME and ISO guidelines to ensure consistent and safe operations across global markets. They enhance equipment safety and maintenance clarity through systematic visualization practices, including color-coded identification, numbered inspection points, and graphical representations, which are strategically implemented to facilitate easy and accurate inspections. By integrating standardized signage, clear landmark placements, and uniform identification methods, FHOPE ensures that maintenance personnel can swiftly and effectively identify crucial components, boosting both efficiency and precision in daily operations.

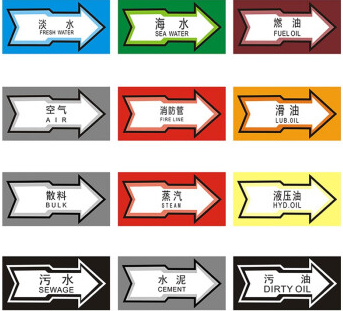

Proper color coding for piping systems is vital in industrial production for several reasons: It enhances safety by helping quickly identify the media in pipes, thus minimizing risks. Clear markings improve efficiency by enabling maintenance personnel to easily locate pipes needing attention. Compliance with regulations ensures adherence to safety standards.

The appropriate color coding for piping systems typically follows these standards:

ANSI/ASME Standards:

Developed by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME), these standards are commonly used in industrial applications. Different colors represent different types of media, such as:

Red: Flammable gases

Green: Water

Yellow: Corrosive materials

Blue: Non-flammable gases

International Standards (ISO):

Some international standards also address pipe identification to ensure consistency across different countries and regions.

National or Local Standards:

Many countries and regions have their own standards, which can usually be found on the websites of relevant industrial or safety management organizations.

Industry Practices:

Certain industries (such as oil and chemical) may have specific color coding conventions that must be followed according to industry standards.

Visibility Considerations:

The choice of colors should also take into account visibility in specific environments to ensure that maintenance personnel can easily identify the pipes.

FHOPE team places great emphasis on various signage and management practices during the production of packaging machines in the workshop.

The visualization methods for equipment inspection points can include the following aspects:

- Numbering: Assigning a number to each inspection point for easy identification and record-keeping.

- Identification: Using colors, labels, or other visual markers to clearly indicate the location of each inspection point.

- Graphical Representation: Creating a graphical layout or diagram of the inspection points to intuitively display their relationships.

- Landmarks/Signage: Setting up noticeable landmarks or signs within the equipment or site environment to facilitate locating each inspection point near.

- Standardization: Adopting a uniform identification method and placement to make the inspection point markings clearer and easier to understand.

The visualization of equipment inspection points aims to use various marking methods to enable maintenance personnel to quickly and intuitively locate and identify each point, thereby improving work efficiency and accuracy. The specific methods employed should be tailored to the actual equipment and site conditions.