HOW TO DO NUMBERING FOR THE COIL PACKING LINE PROJECT

Table of Contents

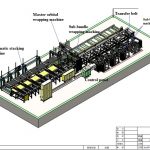

For the coil packing line, the numbering system will be provided a clear and concise clarification on the identification numbers and nameplate information associated with the drawings. This numbering system serves as a foundational element for organizing and tracking the various components, sub-assemblies, and systems within the coil packing line. By establishing a consistent and logical numbering scheme early in the project, all stakeholders can effectively communicate and reference specific parts of the equipment, streamlining the design, manufacturing, and maintenance processes. The timely submission of this information ensures that the project progresses smoothly and efficiently, minimizing the risk of confusion or errors arising from inconsistent or ambiguous identification methods. It will be provided app. 30 dayd after project started.

What is the the principle of the numbering system

The principle of the numbering system for a coil packing line, is designed to ensure clarity, traceability, and efficiency throughout the lifecycle of the equipment, from design and manufacturing to operation and maintenance. Here’s a detailed explanation of the key principles that underpin such a numbering system:

1.Standardization

- Uniform Format: The numbering system should follow a standardized format that is consistently applied across all components and documents. It involve a combination of letters, numbers, and possibly symbols to convey specific information.

- Industry Standards: Where applicable, the system should align with industry standards or norms to facilitate understanding and compliance among various stakeholders, including international partners.

2.Clarity and Simplicity

- Intuitive Design: Our production standard for Intuitive Design mandates that our numbering system be both logical and user-friendly. This approach ensures that anyone familiar with our operations can quickly and accurately decode the information embedded within component identifiers. We emphasize a straightforward, predictable layout that mirrors the functional or structural hierarchy, allowing for immediate understanding and minimal error. Such clarity not only streamlines workflow but also significantly reduces the training burden for new staff, fostering a more efficient and responsive production environment. This standard is pivotal in maintaining consistency and high performance across all our projects.

- Minimal Complexity: Avoid overly complex systems that can lead to confusion or errors. The balance between comprehensive information and simplicity is crucial.

3.Uniqueness and Specificity

- Unique Identification: Each component, assembly, and subsystem should have a unique identifier to prevent any ambiguity.

- Detailed Breakdown: The system can include breakdowns by project phase, component type, and other relevant criteria to pinpoint specific items quickly.

4.Scalability and Flexibility

- Adaptability: The system should be flexible enough to accommodate changes, additions, or customizations without disrupting the existing framework.

- Future Expansion: It should also consider future expansions or modifications to the packing line, allowing for new components or configurations to be integrated seamlessly.

5.Traceability

- Complete Lifecycle Tracking: From procurement and installation to maintenance and replacement, each component’s number should facilitate tracking throughout its lifecycle.

- Easy Reference: This aids in quick referencing in manuals, software, and databases used for the operation and maintenance of the packing line.

6.Integration with Information Systems

- Compatibility: The numbering system should be compatible with any digital systems in place, such as ERP (Enterprise Resource Planning) or PDM (Product Data Management) systems, to ensure that all data linked to a specific number is easily accessible.

- Digital Readability: Consideration for automated systems, such as those using RFID or barcodes that might read and log these numbers for inventory and operational purposes.

Example Implementation in a Coil Packing Line:

It allows for easy tracking of each coil’s production and packaging stage, minimizes errors, and enhances workflow management. This system facilitates quick identification, helps in inventory control, and supports quality assurance processes by ensuring every coil is accounted for and processed according to specifications.

A typical numbering system for a coil packing line include:

Prefix: in our numbering system serves a critical role by indicating the type of item, which streamlines the categorization and retrieval processes. For instance, ‘MC’ is used for mechanical components, and ‘EL’ denotes electrical components. This method not only facilitates quick identification but also enhances the organization of inventory and maintenance schedules. By adopting such prefixes, personnel can immediately recognize the component category, significantly improving efficiency and reducing the likelihood of errors in handling and operations across various departments. This system is integral to our operational strategy, ensuring precision and clarity in component management.

Machine Code: Specific to the each machine with name plate,unique to each unit, is indicated on the machine’s nameplate, serving as a specific identifier for tracking and maintenance purposes.

Sequential Number: A unique sequential number acts as a unique identifier assigned to each packing machine and station function in a series. This number follows a specific order, ensuring that each entry or item is distinctly recognized and can be easily referenced. It serves as a critical component in organizing and tracking systems efficiently, especially in database management, cable and control line identification.

Suffix: Optional, an optional element added to the end of a base term or number to provide additional specifications or indicate revision statuses. It helps in distinguishing between versions, detailing enhancements, or clarifying variations in similar items, making it particularly useful in the drawing searching, documentation, and packing line maintain and identification.