For the wire coil packaging, the wire coil OD normally in the range from 500-900mm with width 300-900mm.

The ring wrapping machine for the coil width upto 900mm would be OD 1900mm. So the big ring for small OD wrapping may caused the poor film control packaging.

The video of coil packing machine shows the coil film wrapping about big ring for small coil OD .

The package surface is full of wringkle by poor tension control.

How to resolve it ?

Apply the right amount of initial tension to the wrapping material. This ensures the material starts to conform to the coil shape from the beginning of the wrapping process. Too little or too much initial tension can cause issues.

Use controlled acceleration and deceleration of the wrapping material during the wrapping cycle. Gradual starts and stops prevent sudden jerks in the material that can cause loose wraps.

Continuously monitor and adjust the tension during wrapping. As the material wraps around the larger diameter middle section of the coil, the effective tension decreases. The tension may need to be increased at that point to maintain an even wrap.

Apply multiple layers of wrapping material with consistent tension between layers. This helps build up a uniformly secure wrap.

Incorporate a tension control knob or setting that can be finely tuned based on the coil size, material type and desired wrap firmness. This allows operators to optimize the settings for different applications.

Perform regular maintenance to ensure components like motors, gears, rollers and idlers maintain consistent performance over time. Any losses in machine efficiency can affect tension control.

Consider incorporating built-in tension sensors that can provide feedback to the PLC control system. This enables more dynamic tension adjustment during the wrapping cycle.

Train operators on how to properly set and monitor the packing tension based on visual inspection of sample wraps. Subtle adjustments may be needed beyond the initial settings.

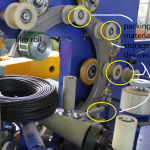

The coil wrapping machine with drawing back device tensioner

By the stretch film tensioner, the machine works for big and small coil wrapping with good package.

Basic operation for keeping a good tension in wire coil packaging:

- Loading and fixing the steel wire coil with supportive rollers

- Adjusting the height level of the ring so for ring ID throug

- Lower the ring 20mm hight than ID side of the wire coil

- Adjusting the tension controller for proper tension.

For more information, feel free contact with info@fhopepack.com