Efficient pallet changing is essential for smooth operations in manufacturing and warehousing. With the right board turning machine, facilities can enhance productivity, reduce manual labor, and improve safety. But with various options available, how do you choose the best board pallet changing machine for your needs? Here’s a comprehensive guide to understanding the features, benefits, and ideal applications for board turning machines in pallet changing.

1. Why Invest in a Board Turning Machine?

1.1 Boosting Efficiency in Pallet Handling

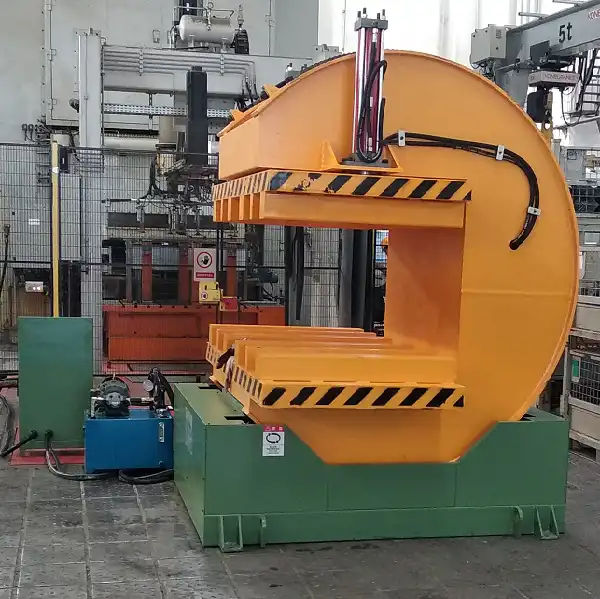

A board turning machine is a specialized tool that simplifies the process of pallet changing, making it faster and safer. By automating the rotation of heavy board loads, these machines minimize the need for manual lifting and turning, reducing the risk of workplace injuries and increasing operational efficiency. For facilities dealing with high volumes of pallet changes, a board turning machine can lead to significant time and cost savings.

1.2 Consistent and Safe Load Handling

Manual pallet turning is not only time-consuming but also poses risks to both products and workers. A board pallet changing machine is designed to handle loads with precision, ensuring the products remain secure during rotation. This consistency is crucial for maintaining the quality of the goods, especially for sensitive items. By investing in a board turning machine, facilities can achieve safe, reliable, and uniform pallet changes that protect both the items and the employees.

1.3 Meeting the Demands of High-Volume Facilities

In high-demand settings, efficiency and speed are paramount. Board turning machines streamline the pallet changing process, allowing facilities to handle higher volumes with ease. This makes them an excellent choice for factories, distribution centers, and logistics companies where timely and safe pallet handling is critical.

2. Types of Board Turning Machines: Which Fits Your Operations?

2.1 Off-Line Board Turning Machines

Off-line board turning machines are ideal for facilities where pallet changes are handled separately from the main production line. These machines are generally operated by forklifts, allowing for easy maneuvering and flexible handling. An off-line board pallet changing machine works well for facilities with limited space or for those that don’t require continuous pallet handling. The off-line system enables operators to bring the load to the turning station, swap out pallets as needed, and return it to production—ideal for intermittent or customized pallet changing needs.

2.2 Online Board Turning Machines for Continuous Operations

Designed for high-throughput environments, online board turning machines integrate seamlessly into a conveyor system, making them a staple in automated facilities. These machines allow for a streamlined pallet changing process that is both quick and consistent. As loads move along the conveyor, the machine handles the rotation and pallet exchange automatically, ensuring there is minimal downtime. An online board pallet changing machine is optimal for operations requiring continuous handling and high productivity.

2.3 Customized Solutions for Unique Requirements

For facilities with specialized needs, custom board turning machines offer tailored solutions that fit specific operational flows and layout restrictions. Customization options include load capacity adjustments, safety features, and integration with existing systems, allowing facilities to maximize their machine’s efficiency. Investing in a custom board turning machine can be beneficial for industries with unique products or pallet sizes, where standard machines might not be suitable.

3. Key Considerations for Choosing a Board Pallet Changing Machine

3.1 Assessing Your Facility’s Layout and Workflow

Before selecting a board pallet changing machine, it’s essential to consider your facility’s layout and workflow. For smaller facilities, off-line machines may provide the necessary flexibility without requiring extensive conveyor systems. In contrast, larger facilities or high-speed production lines may benefit from an online setup that integrates directly with conveyor systems, optimizing the flow and reducing manual intervention.

3.2 Evaluating Load Capacity and Material Compatibility

Not all board turning machines are created equal—some are designed to handle specific weights, while others can accommodate a variety of materials and sizes. Choosing a machine that aligns with your typical load capacity and board type will ensure reliable performance. For example, if your operation handles particularly heavy or delicate items, selecting a board pallet changing machine with advanced weight support and material-specific handling can help avoid damage and maximize efficiency.

3.3 Safety Features for Reliable Operations

Safety is a crucial factor in pallet handling. When evaluating board turning machines, look for features such as secure clamps, automatic load balancing, and emergency stop mechanisms. These safety measures protect both the products and the workers, ensuring that pallet changing remains a controlled and risk-free process. Investing in a board pallet changing machine with enhanced safety features reduces downtime due to accidents and enhances overall facility safety.

4. How to Maximize the Efficiency of Your Board Turning Machine

4.1 Routine Maintenance and Inspections

To keep a board turning machine operating at peak performance, regular maintenance is essential. Conducting routine inspections and addressing minor issues before they escalate ensures the machine’s longevity and reliability. Scheduled maintenance also reduces unexpected downtime, keeping the pallet changing process smooth and uninterrupted.

4.2 Training Staff for Optimal Use

While board turning machines are designed to simplify pallet changes, ensuring staff are properly trained on their operation can maximize their benefits. Proper training helps operators understand the machine’s functions, troubleshoot minor issues, and follow safety protocols. This minimizes potential errors and enhances productivity, ensuring the board pallet changing machine operates at its full potential.

4.3 Leveraging Data and Performance Metrics

Many modern board turning machines come with built-in data tracking and monitoring features. By analyzing performance metrics, facilities can identify patterns, optimize workflows, and make informed decisions to improve the pallet changing process. These insights are invaluable for facilities focused on continuous improvement and can help in achieving optimal efficiency from the machine.

Conclusion: Choosing the Best Board Pallet Changing Machine

When selecting a board turning machine, consider the specific demands of your facility—whether it’s high volume, specialized load requirements, or space constraints. Off-line machines provide flexibility for varied handling, online machines excel in continuous operations, and customized solutions address unique needs. By investing in the right board pallet changing machine, you can streamline operations, improve safety, and boost productivity, setting the foundation for a more efficient and successful workflow.

Get Your Best Solution !