- 1. Understanding the Importance of Flexibility in Long-Term Contracts

- 2. Key Areas Where Flexibility Can Be Incorporated

- 3. Leveraging Multi-Year Service Agreements for Flexibility

- 4. Balancing Long-Term Stability with Contractual Flexibility

- 5. Incorporating Exit Clauses for Unforeseen Circumstances

- 6. Including Innovation and Improvement Clauses

- 7. Performance Monitoring and Reporting Mechanisms

- 8. Ensuring Scalability for Future Growth

- 9. Aligning Contract Length with Flexibility

- 10. Collaborative Partnership for Long-Term Success

- Conclusion: Achieving Flexibility and Long-Term Value in Steel Coil Packing Line Contracts

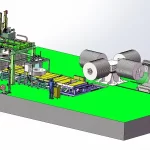

In the steel industry, long-term contracts are essential for securing reliable, cost-effective solutions for steel coil packing operations. However, the rapidly changing nature of the market, coupled with technological advancements, means that building flexibility into these contracts is crucial for maintaining competitiveness and adapting to future needs. Without flexibility, businesses may find themselves locked into outdated terms, inefficient processes, or unnecessary expenses.

This guide will provide a detailed exploration of how businesses can structure long-term steel coil packing line contracts with built-in flexibility to handle evolving demands, new technologies, and unforeseen challenges. Whether you’re negotiating a new contract or revisiting an existing one, understanding how to incorporate adaptability will help you avoid pitfalls and ensure sustainable operations.

1. Understanding the Importance of Flexibility in Long-Term Contracts

In any long-term agreement, especially in industries like steel manufacturing and processing, flexibility is key to success. The market for steel coil packing lines is no exception, as demand can fluctuate due to factors such as economic shifts, technological advancements, and supply chain disruptions.

Why Is Flexibility Important?

Flexibility allows businesses to:

- Adapt to New Technologies: Innovations in packing line automation, IoT integration, and AI-driven systems may become more prevalent during the course of a long-term contract. A flexible contract allows for easy incorporation of these new technologies without needing to renegotiate entirely.

- Respond to Market Changes: Steel market demand can be volatile. Being able to scale operations up or down without hefty penalties helps companies remain competitive.

- Reduce Risk: Locking into rigid terms can expose businesses to risks such as price fluctuations or changing production needs. Flexibility mitigates these risks by providing options to adjust contract terms as necessary.

Examples of Flexibility in Contracts:

- The ability to modify production capacity without incurring penalties.

- Options to upgrade machinery as new technologies emerge.

- Provisions for adjusting service levels in response to fluctuating demand.

By building in these flexible terms, you ensure that your long-term contract remains viable and profitable, even as the industry evolves.

2. Key Areas Where Flexibility Can Be Incorporated

When negotiating or drafting a long-term steel coil packing line contract, there are several key areas where flexibility can and should be incorporated. These areas include pricing, technology upgrades, production capacity, and service agreements.

2.1 Flexible Pricing Models

One of the most important aspects of a steel coil packing line contract is the pricing structure. A rigid pricing model may not account for market fluctuations or changes in the cost of raw materials, making it essential to include flexibility here.

Pricing Adjustments:

- Indexed Pricing: Contracts can include provisions for adjusting prices based on market indices or the cost of raw materials.

- Volume-Based Discounts: Ensure that your contract includes the ability to renegotiate prices if production volumes change significantly over time.

- Incentive-Based Pricing: Incorporate incentives that reward the supplier for achieving cost-efficiencies or providing added value.

By including pricing flexibility, you can avoid being locked into rates that may no longer reflect market conditions.

2.2 Technology Upgrade Options

The technology used in steel coil packing lines is continually advancing, with automation, smart systems, and data-driven solutions becoming more sophisticated. To avoid being stuck with outdated technology, it’s critical to include clauses that allow for upgrading machinery and integrating new systems as needed.

Upgrade Provisions:

- Technology Refresh Clauses: Include terms that allow for the upgrading of machinery during the contract term without significant penalties.

- Future-Proofing: Work with suppliers who offer equipment that can easily integrate with future technologies, ensuring your packing line remains cutting-edge.

- Cost-Sharing: Negotiate terms where both parties share the cost of major technology upgrades to maintain efficiency without bearing the entire financial burden.

These upgrade options keep your operations aligned with the latest industry standards, ensuring you remain competitive in a fast-paced market.

2.3 Production Capacity Flexibility

In the steel industry, demand can fluctuate due to factors like economic cycles, supply chain disruptions, or changes in end-market needs. A contract with fixed production capacity requirements can be limiting if demand shifts dramatically.

Capacity Adjustment Clauses:

- Scalability Options: Ensure your contract includes provisions to scale production capacity up or down, allowing your packing line to adjust to current demand without incurring penalties.

- Flexible Labor Requirements: Include clauses that allow you to modify labor requirements (e.g., automation vs. manual labor) depending on operational needs.

- Off-Peak Adjustments: For companies with seasonal production needs, the contract should include options to reduce or increase production during off-peak periods.

Incorporating flexibility in production capacity allows you to remain agile and responsive, minimizing waste and maximizing efficiency even when demand fluctuates.

3. Leveraging Multi-Year Service Agreements for Flexibility

Many steel coil packing line contracts include service agreements for maintenance, repairs, and equipment upgrades. While these service agreements are essential for ensuring the longevity and efficiency of the packing line, they also need to be flexible to accommodate evolving business needs.

Flexible Service Contracts:

- Variable Maintenance Schedules: Depending on usage, you may need more or fewer maintenance visits. Ensure that your contract allows for the adjustment of service schedules based on actual operational needs.

- Performance-Based Metrics: Tie service agreements to performance metrics rather than fixed schedules, ensuring that services are rendered when needed, not just at preset intervals.

- Option for Remote Monitoring: With the advent of IoT and remote diagnostics, some service agreements may include provisions for remote monitoring and troubleshooting. This reduces downtime and eliminates the need for frequent in-person visits.

A flexible service contract ensures that your packing line is always running at peak performance without the inefficiency of rigid maintenance schedules or unnecessary repairs.

4. Balancing Long-Term Stability with Contractual Flexibility

While flexibility is critical, there must also be a balance between long-term stability and adaptability. Too much flexibility may introduce unpredictability or undermine the security of the contract. Therefore, it’s essential to structure the contract in a way that both protects the long-term interests of the company and allows for adaptability when necessary.

How to Find the Balance:

- Core Terms vs. Variable Terms: Keep certain core terms of the contract, such as fundamental service level agreements (SLAs), pricing thresholds, and contract length, stable, while introducing flexibility into other aspects such as technology upgrades, volume adjustments, and operational changes.

- Change Control Procedures: Include clear procedures for how changes can be made to the contract. This ensures that any adjustments are carefully reviewed, negotiated, and agreed upon, maintaining stability while allowing necessary flexibility.

- Risk-Sharing: Share the risks associated with flexibility between the supplier and the buyer. For example, if market conditions drastically change, both parties can agree to split the costs or savings generated by those changes.

Finding this balance is essential for ensuring that your contract remains stable while being flexible enough to meet future demands.

5. Incorporating Exit Clauses for Unforeseen Circumstances

No long-term contract should be without exit clauses that allow both parties to end the agreement under certain conditions. However, these exit clauses should be structured carefully to avoid undue risk or financial burden.

Types of Exit Clauses:

- Force Majeure: Include provisions that allow for contract termination in the event of unforeseeable circumstances such as natural disasters, major economic shifts, or pandemics.

- Performance-Related Exits: Ensure that there are clauses in place that allow for termination if the supplier fails to meet critical performance benchmarks consistently.

- Penalty-Free Early Exits: Negotiate for the option to terminate the contract early if business needs change drastically, provided sufficient notice is given.

Exit clauses provide a safety net for unforeseen circumstances, ensuring that you are not trapped in a contract that no longer aligns with your business goals.

6. Including Innovation and Improvement Clauses

As the steel industry evolves, advancements in packaging technologies are inevitable. Incorporating innovation clauses into your long-term steel coil packing line contract ensures that your operations stay competitive and efficient. These clauses require both parties to actively seek opportunities for improvement and innovation during the contract’s duration, fostering a continuous improvement mindset.

What to Include in Innovation Clauses:

- Technology Upgrades: Specify regular reviews to evaluate the incorporation of new technologies such as automation upgrades, AI-driven solutions, or improvements in material efficiency.

- Process Optimization: Include provisions that allow for the integration of process improvements as they become available, ensuring that your packing line remains efficient over time.

- Collaborative R&D: Consider partnering with the supplier on research and development (R&D) efforts, which may yield cost-saving innovations or process enhancements that benefit both parties.

By fostering innovation and encouraging collaboration, your packing line will continuously evolve, ensuring peak performance throughout the contract term.

7. Performance Monitoring and Reporting Mechanisms

Building flexibility into a long-term contract isn’t just about having the option to make changes—it’s about ensuring that those changes are data-driven and necessary. Including performance monitoring and reporting mechanisms ensures that both parties stay informed about the packing line’s performance, allowing for timely adjustments.

Key Elements to Include:

- Key Performance Indicators (KPIs): Define clear KPIs such as uptime, production capacity, and efficiency metrics that both parties agree to monitor.

- Regular Performance Reviews: Schedule regular performance reviews (e.g., quarterly or biannually) to assess whether the equipment and operations are meeting the agreed-upon standards.

- Data Transparency: Ensure that both parties have access to the data generated by the packing line, allowing for shared insights and informed decision-making.

Performance monitoring ensures that flexibility is applied when necessary and in response to concrete data, rather than speculation or assumptions.

8. Ensuring Scalability for Future Growth

The steel industry is subject to cyclical fluctuations in demand, and your business’s needs today may not reflect what they will be in five or ten years. A truly flexible long-term contract will include provisions for scalability, allowing you to adjust your packing line capacity as your business grows.

How to Build Scalability into the Contract:

- Modular Equipment Options: Consider packing lines that can be expanded or reduced in capacity by adding or removing components, making it easier to scale up or down as needed.

- Flexible Labor Agreements: For hybrid lines that combine automation with manual labor, ensure that the contract allows for adjustments in labor levels to reflect your changing operational needs.

- Capacity Reviews: Schedule capacity reviews to adjust the contract terms based on production forecasts, ensuring that the packing line continues to meet your needs without requiring a full contract renegotiation.

By building scalability into your contract, you ensure that your business remains agile and prepared for future growth or changes in market demand.

9. Aligning Contract Length with Flexibility

The length of the contract plays a significant role in how much flexibility you need to build in. The longer the contract, the more flexibility you should incorporate, given that the market, technology, and business needs will likely change over time. Conversely, a shorter contract may require less flexibility, as the terms can be reassessed and updated more frequently.

Factors to Consider in Contract Length:

- Short-Term vs. Long-Term Needs: Assess your business’s current needs and long-term goals to determine whether a short-term or long-term contract is more suitable.

- Renewal Options: Include options for renewing the contract with updated terms, ensuring that both parties can reassess and adjust the contract based on new conditions.

- Exit Strategies: Build exit strategies that allow for early termination or renegotiation if your business undergoes significant changes, such as a merger, acquisition, or pivot in operations.

Aligning contract length with built-in flexibility ensures that the agreement remains relevant throughout its duration, providing stability while allowing for necessary adjustments.

10. Collaborative Partnership for Long-Term Success

A flexible long-term contract should be based on a collaborative partnership between the buyer and supplier. By fostering open communication, mutual trust, and a shared commitment to success, both parties can benefit from a contract that is adaptable, efficient, and beneficial for the long term.

Building a Collaborative Partnership:

- Clear Communication Channels: Establish regular communication to discuss performance, potential challenges, and opportunities for improvement.

- Joint Problem-Solving: Approach challenges and changes collaboratively, ensuring that both parties work together to find solutions that benefit both sides.

- Mutual Growth: Structure the contract in a way that promotes mutual growth, allowing both parties to benefit from improvements in efficiency, technology, and cost savings.

A collaborative approach ensures that the contract remains beneficial for both the buyer and the supplier, fostering long-term success and satisfaction.

Conclusion: Achieving Flexibility and Long-Term Value in Steel Coil Packing Line Contracts

Building flexibility into a long-term steel coil packing line contract is essential for ensuring that your operations remain competitive, efficient, and adaptable to future needs. By incorporating provisions for pricing adjustments, technology upgrades, capacity changes, and innovation, you can ensure that your business is equipped to handle market fluctuations, technological advancements, and evolving production requirements.

Whether you’re negotiating a new contract or revisiting an existing one, focusing on flexibility will help you reduce risk, optimize costs, and ensure that your packing line remains a valuable asset to your business for years to come. By fostering a collaborative partnership with your supplier, you can create a contract that delivers long-term value while maintaining the agility needed to adapt to an ever-changing market.