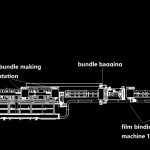

Steel wire coil coiling and strapping machine by PP.

How Automation Solves the High Labor Intensity in Steel Wire Coil Packaging

In the dynamic world of steel manufacturing, the packaging of steel wire coils presents unique challenges. High labor intensity, potential for human error, and safety risks are prevalent issues. However, automation has emerged as a transformative solution, streamlining processes and enhancing efficiency. This article explores how automation addresses these challenges and revolutionizes the steel wire coil packaging industry.

Understanding Steel Wire Coil Packaging

The Importance of Proper Packaging

Steel wire coils require secure packaging to prevent damage during transportation and storage. Proper packaging ensures product integrity and quality, protecting both the manufacturer’s reputation and customer satisfaction.

Traditional Packaging Methods

Historically, packaging steel wire coils has been a labor-intensive process. Manual handling involves wrapping, securing, and loading coils, often leading to inefficiencies and inconsistencies.

Challenges of Manual Packaging

High Labor Intensity

Manual packaging demands significant physical effort, leading to high labor costs and increasing the risk of worker fatigue. This intensity can result in slower production rates and reduced operational efficiency.

Inconsistency and Errors

Human involvement introduces the potential for inconsistencies and errors. Variations in wrapping tightness or securing methods can compromise coil stability, increasing the likelihood of damage during transit.

Safety Risks

The physical demands of manual packaging pose safety risks, including injuries from heavy lifting and repetitive strain. Ensuring a safe working environment becomes more challenging with manual processes.

Limited Scalability

As demand for steel products grows, scaling up operations with manual methods becomes impractical. Manual packaging limits the ability to meet high production demands efficiently.

The Rise of Automation in Packaging

Introduction to Automated Solutions

Automation involves using machines and technology to perform packaging tasks traditionally done by human workers. In the steel industry, automated solutions have transformed how wire coils are packaged, offering numerous benefits.

Key Features of Automated Packaging Systems

Modern automated systems boast features such as programmable settings, real-time monitoring, and precision control. These capabilities ensure consistent, high-quality packaging that meets industry standards.

Advantages of Automation in Steel Wire Coil Packaging

Enhanced Efficiency and Productivity

Automated systems significantly enhance efficiency by reducing the time required to package each coil. This increase in productivity allows manufacturers to meet higher demands without compromising quality.

Consistency and Precision

Automation ensures consistent tension and precise wrapping, reducing the risk of damage. This precision enhances product safety during transportation and ensures uniformity across all packaged products.

Reduction in Labor Costs

By automating labor-intensive tasks, companies can reduce their reliance on manual labor. This shift not only cuts costs but also reallocates human resources to more strategic roles, improving overall operational efficiency.

Improved Safety

Automation minimizes the need for direct human intervention, reducing the risk of workplace injuries. By handling heavy lifting and repetitive tasks, machines create a safer work environment for employees.

Scalability and Flexibility

Automated packaging systems offer scalability, allowing businesses to easily adjust production levels in response to market demands. This flexibility ensures that manufacturers can efficiently manage both small and large-scale operations.

Technological Advancements in Automated Packaging

Smart Technology Integration

The integration of smart technology enhances automated packaging systems. Features such as IoT connectivity and data analytics provide real-time insights, optimizing performance and reducing downtime.

AI and Machine Learning

AI-driven solutions enable machines to learn and adapt to production needs, further improving efficiency. Machine learning algorithms can optimize packaging processes, ensuring optimal settings for different coil types.

Sustainable Packaging Solutions

With a growing focus on sustainability, automated systems now accommodate eco-friendly packaging materials. These advancements help reduce environmental impact and align with corporate responsibility goals.

Real-World Applications and Success Stories

Case Study: Leading Steel Manufacturer

A prominent steel manufacturer integrated automated packaging systems, resulting in a 50% increase in productivity and a 40% reduction in labor costs. This transition allowed the company to meet rising demand while maintaining high safety standards.

Case Study: Industrial Steel Supplier

An industrial steel supplier adopted smart packaging solutions, achieving a significant decrease in product damage during transit. This improvement led to enhanced customer satisfaction and strengthened market position.

Overcoming Challenges with Automation

Initial Investment and Implementation

While the initial investment for automation can be substantial, the long-term benefits, including cost savings and efficiency gains, justify the expense. Strategic planning and phased implementation can ease the transition.

Employee Training and Adaptation

To maximize the benefits of automation, training employees to operate and maintain new systems is crucial. This training ensures a smooth transition and empowers staff to leverage technology effectively.

Continuous Improvement and Innovation

The dynamic nature of technology requires ongoing improvement and innovation. Businesses must stay abreast of advancements to maintain a competitive edge and ensure optimal system performance.

Future Trends in Automated Steel Packaging

Increased Customization

As demand for customized solutions grows, future automated systems will offer greater flexibility. Manufacturers will be able to tailor packaging processes to specific product requirements, enhancing both efficiency and customer satisfaction.

Focus on Energy Efficiency

The push for energy-efficient solutions will drive innovation in automated packaging. Future machines will aim to reduce energy consumption, supporting sustainability goals while lowering operational costs.

Advanced Data Analytics

The use of advanced data analytics will further enhance automated packaging systems. By analyzing performance metrics, businesses can optimize processes and make informed decisions to improve efficiency.

Conclusion

In conclusion, automation offers transformative solutions to the high labor intensity challenges in steel wire coil packaging. By enhancing efficiency, consistency, and safety, automated systems provide a competitive edge for manufacturers. While the transition to automation requires investment and adaptation, the long-term benefits, including cost savings and scalability, make it a worthwhile endeavor. Embracing advanced packaging solutions not only improves productivity but also positions businesses to thrive in an increasingly competitive market. Through continuous innovation and strategic implementation, the future of steel wire coil packaging is undoubtedly automated.