Horizontal vs Vertical Stretch Wrapping Machines

When it comes to packaging products efficiently, stretch wrapping machines play a crucial role in ensuring that goods are secured for transport and storage. Among these machines, horizontal and vertical stretch wrapping machines are the two primary types. Understanding their differences, similarities, and the products they are best suited for can help businesses make informed decisions.

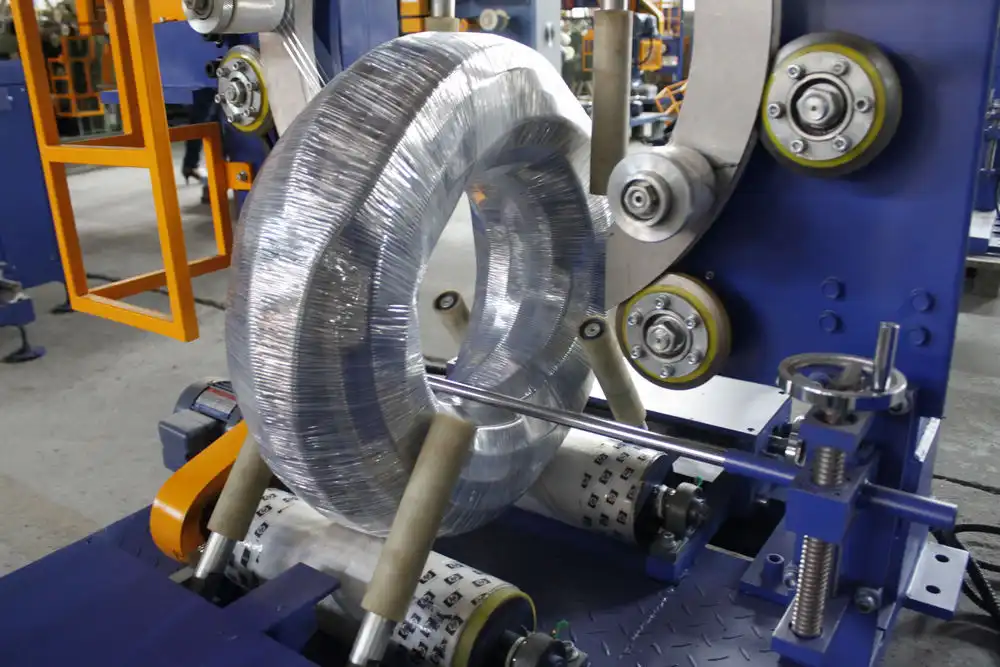

What are Horizontal Stretch Wrapping Machines?

Horizontal stretch wrapping machines are designed to wrap products as they move along a conveyor system. A key feature of these machines is the rotary ring, which encircles the product and applies stretch film tightly around it. This method of wrapping is particularly effective for longer or bulkier items that might be difficult to handle with vertical machines.

Horizontal machines are ideal for wrapping products such as:

Cabinets

Doors

Windows

Lumber

Copper pipes

Corrugated tubing

Carpets and other textiles

The ability to wrap large and awkwardly shaped items makes horizontal stretch wrapping machines an efficient choice for many manufacturing and distribution industries.

What are Vertical Stretch Wrapping Machines?

Vertical stretch wrapping machines, on the other hand, come in two main configurations: those with a turntable and those with a rotary arm. In a turntable system, the pallet of goods is rotated while the stretch film is applied from above. This design is effective for stable loads weighing up to 4,400 pounds and is space-efficient, making it suitable for facilities with limited floor space.

In contrast, the rotary arm system keeps the pallet stationary while the arm moves around it, wrapping the product. This approach is beneficial for packaging items that are too heavy, too light, or unstable, as it minimizes the risk of shifting during the wrapping process.

Vertical stretch wrapping machines are commonly used for products such as:

Palletized goods

Heavy machinery

Boxes and containers

Irregularly shaped items

Differences and Similarities Between the Two Machines

While both horizontal and vertical stretch wrapping machines serve the same primary purpose of securing products for storage and transport, they differ significantly in their design and application. Horizontal machines excel in wrapping long and bulky items, while vertical machines are better suited for palletized goods and stable loads.

Both types of machines can be found in automatic and semi-automatic configurations. Automatic machines require minimal human intervention, maximizing speed and consistency. Semi-automatic machines, however, may require some manual input, such as loading pallets or initiating the wrapping process.

How to Choose the Right Stretch Wrapping Machine

When selecting a stretch wrapping machine, several factors should be considered:

1. Product Type: Assess the dimensions and weight of the products you need to wrap. Horizontal machines are better for longer items, while vertical machines are ideal for palletized goods.

2. Production Volume: Evaluate your production needs—higher volumes might benefit from automatic machines, while lower volumes may be adequately served by semi-automatic options.

3. Available Space: Consider the footprint of the machine and the layout of your facility. Turntable machines occupy less space than rotary arm machines.

4. Budget: Determine your budget for equipment and maintenance, as both types of machines come with varying price points.

For expert guidance in selecting the right stretch wrapping machine for your needs, contact FHOPE, a specialist in stretch wrapping technology. Our team can provide tailored solutions to optimize your packaging process, ensuring efficiency and reliability in your operations.