Hidden Costs in Aluminum Profile Packaging and How to Avoid Them

In the world of manufacturing and logistics, aluminum profile packaging plays a crucial role in ensuring the integrity and safety of products during transit. However, many businesses often overlook the hidden costs associated with this packaging. Understanding these costs is essential for maximizing profitability and ensuring smooth operations. In this article, we will delve deep into the various hidden costs in aluminum profile packaging and provide actionable strategies to avoid them.

Understanding Aluminum Profile Packaging

What Are Aluminum Profiles?

Aluminum profiles are extruded sections made from aluminum alloys, characterized by their lightweight and high strength. These profiles are widely used in construction, automotive, and various industrial applications. Due to their versatility, they require specialized packaging to protect them during shipping and storage.

Importance of Proper Packaging

Proper packaging is not just about aesthetics; it ensures that the profiles arrive at their destination without damage. This is vital for maintaining customer satisfaction and avoiding costly returns. However, the packaging process can introduce several hidden costs that businesses need to be aware of.

Identifying Hidden Costs

1. Material Costs

While the initial cost of aluminum profiles is often highlighted, the packaging materials themselves can incur significant expenses. Many companies opt for cheaper alternatives to save costs, but this can lead to increased damage rates.

Tip: Invest in high-quality packaging materials that provide adequate protection. This may seem like a higher upfront cost but can save money in the long run by reducing damage and returns.

2. Labor Costs

Labor costs connected to packaging can often be underestimated. Inefficient packing processes can lead to longer packaging times and increased labor costs.

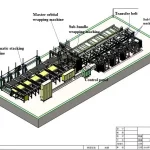

Tip: Streamline your packaging process through training and efficient layout designs. Automating parts of the packaging process can also reduce labor costs significantly.

3. Shipping Costs

The weight and dimensions of aluminum profile packaging can greatly affect shipping costs. Oversized or improperly packed items may require more space, leading to higher freight charges.

Tip: Use precise measurements and optimized packaging designs to minimize shipping costs. Consider dimensional weight pricing used by carriers and adapt your packaging accordingly.

4. Damage and Returns

Product damage during transit can lead to costly returns and replacements. Hidden costs associated with damage include not only the cost of the product itself but also the associated shipping and handling costs.

Tip: Implement better protective measures, such as corner protectors and foam inserts, to safeguard aluminum profiles during transit.

5. Waste Management

Improper packaging can lead to excess waste, which not only has environmental implications but also financial ones.

Tip: Optimize packaging designs to minimize waste and consider recyclable materials. This will not only reduce costs but also enhance your brand’s sustainability image.

6. Inventory Holding Costs

Overpacking or improper storage can lead to increased inventory holding costs. If items are damaged or need to be repackaged, it affects your inventory turnover rate.

Tip: Maintain an efficient inventory management system that tracks packaging needs and supplies accurately. This helps avoid overstocking and reduces holding costs.

7. Compliance Costs

Various regulations govern packaging, especially for international shipping. Non-compliance can lead to fines and delays.

Tip: Stay informed about packaging regulations in the regions you operate. Ensuring compliance from the start can save you from unexpected costs.

8. Opportunity Costs

Time spent on handling damaged goods or inefficient packaging processes could be better spent on productive tasks.

Tip: Assess your packaging process regularly to identify bottlenecks and opportunities for improvement. Investing time in optimizing your packaging can improve overall productivity.

9. Insurance Costs

Higher risk of damage can lead to increased insurance premiums. If your packaging is not adequately protecting your products, you might find your insurance costs climbing.

Tip: Consult with your insurance provider to understand how packaging affects your premiums and explore options for better coverage.

10. Lost Sales Opportunities

When products are frequently damaged or delayed due to poor packaging, it can lead to lost sales opportunities. Customers may turn to competitors if they cannot rely on timely and intact deliveries.

Tip: Invest in reliable packaging solutions that ensure products arrive on time and in perfect condition, thus retaining customer trust and loyalty.

Strategies to Mitigate Hidden Costs

Now that we’ve identified the hidden costs associated with aluminum profile packaging, let’s explore some effective strategies to mitigate these expenses.

Optimize Your Packaging Design

Investing time in packaging design can yield significant savings. Use software to create optimized designs that minimize material use while maximizing protection.

Utilize Smart Technology

Incorporate smart technology into your packaging process. For example, sensors can monitor the condition of packages during transit, providing real-time data that can help prevent damage.

Choose the Right Packaging Partner

Select a packaging partner who understands the nuances of aluminum profile packaging. A knowledgeable partner can help you choose the best materials and techniques to minimize costs.

Regular Training for Staff

Conduct regular training sessions for your packaging staff. Well-trained employees are more efficient and less likely to make mistakes that could lead to increased costs.

Implement Lean Practices

Adopt lean manufacturing principles in your packaging process. This involves reducing waste and improving efficiency, which can lead to significant cost savings.

Monitor and Analyze Data

Use data analytics to monitor your packaging process. By analyzing shipping data, you can identify patterns that lead to damage and take corrective action.

Foster Supplier Relationships

Build strong relationships with your suppliers. A good partnership can lead to better pricing on materials and access to innovative packaging solutions.

Evaluate Packaging Materials Regularly

Regularly review your packaging materials to ensure they meet your current needs. Transitioning to new materials or suppliers can often lead to cost savings.

Consider Custom Solutions

Invest in custom packaging solutions tailored specifically for your aluminum profiles. Custom solutions can enhance protection and reduce waste, ultimately saving costs.

Stay Informed on Industry Trends

Keeping abreast of industry trends can provide insights into new packaging methods that may reduce costs. Subscribe to industry publications and attend trade shows to stay informed.