A film tapping machine for aluminum profiles is a machine used to apply protective films or tapes onto the four sides of aluminum profiles. These films are typically applied to protect the aluminum surface from scratches, dirt, or damage during transportation, handling, or fabrication processes.

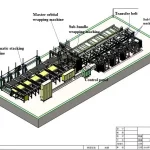

The film tapping machine is designed to automate the process of applying the protective film, making it faster and more efficient compared to manual application. It typically consists of the following components:

- Feeding System: This system is responsible for feeding the aluminum profiles into the machine for film application. It may use rollers or belts to transport the profiles.

- Film Roll Holder: The machine is equipped with holders for the film rolls. These rolls contain the protective film that will be applied to the aluminum profiles.

- Film Application Mechanism: This mechanism is designed to unroll the film from the roll and apply it onto the four sides of the aluminum profiles. It may use adhesive or static electricity to ensure the film adheres properly to the surface of the profiles.

- Cutting System: After the film is applied, the machine may have a cutting system to trim the film at the desired length. This ensures neat and precise application of the film.

- Control Panel: The machine is controlled through a control panel where the operator can set parameters such as film length, speed, and other relevant settings.

The film tapping machine offers several advantages, including increased productivity, consistent film application, reduced labor costs, and improved product quality. It is commonly used in industries that manufacture and process aluminum profiles, such as construction, automotive, and furniture industries.

It’s important to note that specific features and capabilities may vary among different manufacturers and models of film tapping machines, so it’s advisable to consult the machine’s manual or contact the manufacturer for detailed instructions on its operation and capabilities.