Comparing Pallet Inverter Lifespan: Which Models Last the Longest?

Introduction

Investing in a pallet inverter is a significant decision for any operation focused on material handling efficiency. Beyond the initial cost, the operational lifespan of the equipment is a critical factor influencing long-term value and return on investment (ROI). Whether transferring loads, replacing damaged pallets, or complying with hygiene standards, selecting a durable pallet inverter minimizes disruptions and lowers the total cost of ownership. This guide explores the factors determining pallet inverter longevity, compares different types, and offers insights into choosing models known for extended service life.

Why Pallet Inverter Lifespan Matters

The operational life of a pallet inverter directly impacts several key business metrics:

- Maintenance Costs and Downtime: A machine with a short lifespan inherently requires more frequent repairs, component replacements, and servicing. Unplanned downtime can halt production or logistics, leading to significant operational costs and lost revenue. Durable models require less intervention, ensuring smoother workflows.

- Productivity and Efficiency: Consistent, reliable equipment performance is essential for maintaining throughput. A long-lasting pallet inverter supports sustained productivity levels without the frequent interruptions associated with less robust machinery.

- Capital Expenditure: Choosing an inverter built for longevity reduces the frequency of major capital investments. This frees up financial resources that can be allocated to other strategic areas of the business.

- Total Cost of Ownership (TCO): While durable models might have a higher initial purchase price, their extended lifespan, lower maintenance costs, and reduced downtime often result in a significantly lower TCO compared to cheaper, less reliable alternatives.

- Safety: Well-maintained, high-quality equipment is generally safer to operate. Age and wear can compromise safety mechanisms, making longevity, coupled with proper upkeep, a factor in workplace safety.

Types of Pallet Inverters and Their Durability Characteristics

Pallet inverters come in various designs, each with implications for durability and lifespan. Understanding these differences is key to selecting the right machine for your needs:

1. Stationary Pallet Inverters

- Description: Fixed-position machines, often integrated into conveyor lines or dedicated work cells, designed for high-volume, repetitive tasks.

- Durability Profile: Generally offer excellent durability and a long lifespan due to robust, heavy-duty construction and fewer stresses from movement. Their stability reduces wear on structural components.

- Considerations: Longevity is highly dependent on adhering to recommended maintenance and servicing schedules, particularly for hydraulic and electrical systems. They are less flexible in terms of location.

2. Mobile Pallet Inverters

- Description: Offer operational flexibility, allowing pallet inversion at various locations within a facility. Often feature wheels or pallet truck bases.

- Durability Profile: Mobility can introduce additional wear and tear, especially on wheels, steering mechanisms, and power systems (batteries in electric models). Their lifespan can be shorter than stationary models if subjected to rough floor conditions or intensive, constant movement without proper upkeep.

- Considerations: Build quality varies significantly. Heavy-duty mobile units can still offer reliable performance and good longevity with regular maintenance focused on mobile components.

3. Hydraulic Pallet Inverters

- Description: Utilize hydraulic systems (pumps, cylinders, valves) for clamping and rotation/tilting actions. Known for power and precision, suitable for heavy or uneven loads.

- Durability Profile: Hydraulic systems are generally highly durable and capable of handling significant forces. Key components like seals, hoses, and pumps require regular inspection and maintenance to prevent leaks and ensure optimal performance.

- Considerations: With proper care (fluid checks, filter changes, seal replacements), hydraulic pallet inverters can achieve a very extended lifespan, even in demanding industrial environments. Neglecting hydraulic maintenance is a primary cause of premature failure.

4. Mechanical Pallet Inverters

- Description: Employ mechanical systems like gears, chains, sprockets, and screw mechanisms for inversion. Often simpler in design compared to hydraulic models.

- Durability Profile: Can offer good durability, particularly if constructed with heavy-duty steel components and high-quality mechanical parts. They may have lower maintenance demands related to fluid systems but require regular lubrication and tensioning of chains/belts.

- Considerations: The quality of materials and precision of manufacturing are critical. Lighter-duty mechanical models may wear out faster under high loads or frequent use compared to their hydraulic counterparts or heavy-duty mechanical options.

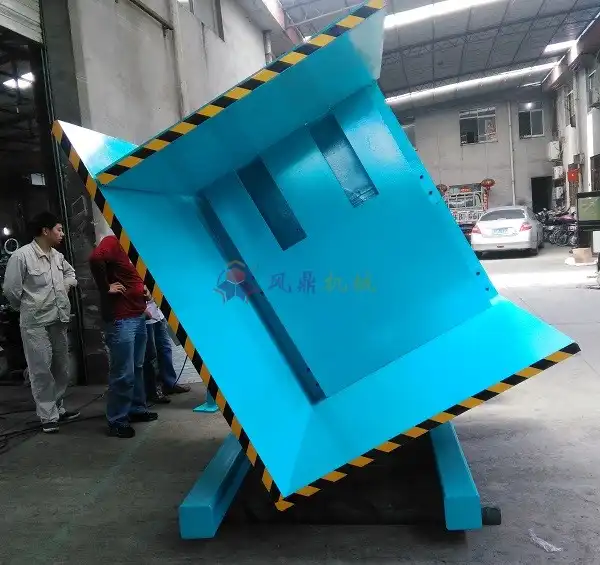

pallet inverter4 Key Factors That Influence Pallet Inverter Lifespan

Beyond the basic type, several specific factors significantly impact how long a pallet inverter will last:

1. Build Quality and Materials

- Impact: This is arguably the most critical factor. Inverters constructed from heavy-gauge structural steel, with quality welds and robust components (e.g., high-grade bearings, motors, hydraulic parts), inherently last longer.

- Indicators: Look for details on frame thickness, component suppliers, and overall machine weight (often correlates with robustness). Avoid models using light-gauge steel or lower-quality plastic components in critical areas. High replacement costs often follow low initial prices linked to inferior materials.

2. Usage Frequency and Intensity

- Impact: A pallet inverter used continuously in a 3-shift operation will experience more wear than one used a few times per day. Similarly, consistently handling loads near the machine's maximum rated capacity imposes greater stress.

- Considerations: Match the inverter's duty rating to your operational demands. Investing in a heavy-duty model is crucial for high-volume operations to achieve a reasonable track record for longevity.

3. Maintenance Practices and Servicing Schedule

- Impact: Regular maintenance is non-negotiable for extending equipment life. Proactive checks, lubrication, adjustments, and timely replacement of worn parts (seals, filters, chains, bearings) prevent minor issues from escalating into major failures.

- Best Practice: Follow the manufacturer's recommended maintenance schedule diligently. Maintain detailed service logs. Even low-maintenance models benefit from regular inspections. Neglect is a primary driver of premature equipment failure and shortened lifespan.

4. Operating Environment

- Impact: The surrounding conditions affect longevity. Harsh environments – those with excessive dust, debris, moisture, corrosive substances (e.g., salt), or extreme temperatures (freezers, foundries) – accelerate wear and corrosion.

- Considerations: Choose models designed for specific environments (e.g., stainless steel or galvanized finishes for washdown areas, sealed components for dusty locations). Operating in clean, dry, temperature-controlled environments typically promotes a longer lifespan.

How to Maximize the Lifespan of Your Pallet Inverter

While choosing a durable model is essential, proactive measures can significantly extend its operational life:

1. Implement a Rigorous Maintenance Schedule

- Action: Develop and adhere to a preventive maintenance plan based on manufacturer recommendations and usage intensity.

- Tasks: Include daily operator checks, weekly inspections (e.g., fluid levels, unusual noises), monthly lubrication, and periodic professional servicing. Document all maintenance activities.

2. Ensure Proper Operator Training

- Action: Train all operators on correct operating procedures, weight limits, load centering, emergency stops, and basic troubleshooting.

- Benefit: Prevents damage caused by misuse, overloading, or incorrect handling. Well-trained operators are also better at identifying early signs of malfunction, preventing minor issues from becoming major repairs. Operator training is a direct investment in equipment longevity.

3. Use Within Rated Capacity and Specifications

- Action: Strictly adhere to the manufacturer's specified load capacity and operational limits. Avoid consistently overloading the machine.

- Benefit: Reduces stress on structural components, motors, and hydraulic/mechanical systems, preventing premature wear and failure.

4. Maintain a Clean Operating Area

- Action: Keep the area around the pallet inverter free from debris, dirt, and spills.

- Benefit: Prevents contaminants from entering critical components (e.g., bearings, hydraulic systems) and reduces the risk of corrosion or jamming.

5. Upgrade Components When Sensible

-

Action: Consult with the manufacturer or service provider about potential upgrades for wear parts (e.g., more durable seals, higher-quality bearings) when replacements are needed.

-

Benefit: While maintaining OEM specifications is often key, technological advancements might offer more resilient components that can enhance longevity beyond the original design.

pallet inverter factory (8) 6. Store Equipment Properly When Not In Use

-

Action: If mobile or stored seasonally, keep the inverter in a clean, dry environment, protected from the elements.

-

Benefit: Prevents corrosion and degradation of components during periods of inactivity.

Get Your Best Solution !

Examples of Pallet Inverter Models/Features Associated with Longevity

While brand specifics can vary, certain design philosophies and features are often associated with long-lasting pallet inverters:

- Heavy-Duty Steel Construction: Models explicitly marketed as "heavy-duty," often featuring thicker steel frames (e.g., quarter-inch plate or more) and reinforced clamping and rotation mechanisms. The overall weight can be an indicator.

- Quality Hydraulic Systems: Inverters using reputable hydraulic component brands (e.g., Parker, Eaton) known for reliability and parts availability. Look for well-protected hoses and cylinders.

- Robust Mechanical Drives: For mechanical types, look for oversized gears, heavy-duty chains (e.g., ANSI standard roller chains), and high-quality bearings, often housed securely.

- Simplicity and Serviceability: Designs that minimize unnecessary complexity and provide easy access to key service points (lubrication points, filters, adjustment mechanisms) tend to be better maintained, contributing to longevity.

- Application-Specific Designs: Models tailored for demanding environments, such as stainless steel construction for food/pharma washdown areas or specialized seals for cold storage, demonstrate a focus on durability under specific conditions.

Note: While specific models like the Premier Pallet Systems range, certain Loadhog Pally & Lid systems, or Toppy Pharma Advance are often cited for durability in their respective niches due to factors like robust build or specialized design, evaluating based on the features above provides a more general framework.

Comparing Lifespan Across Different Industries

The expected lifespan of a pallet inverter can be influenced by the typical demands of the industry it serves:

1. Warehousing and Logistics

- Demands: Often high cycle counts, focus on speed and efficiency. Environment is generally controlled but can be dusty.

- Lifespan Factors: Longer lifespans are achievable with proper maintenance, but high usage necessitates robust construction. Stationary models integrated into lines often fare well.

2. Food and Beverage Industry

- Demands: Strict hygiene requirements, frequent washdowns, potential exposure to moisture and cleaning chemicals. Loads can vary (e.g., fragile bottles, heavy liquid totes).

- Lifespan Factors: Requires corrosion-resistant materials (stainless steel is common). Regular, thorough cleaning is essential but can also introduce moisture challenges if seals aren't maintained. Specialized washdown-rated models generally last longer here.

3. Pharmaceutical Industry

- Demands: Extreme cleanliness (cleanroom compatibility sometimes needed), precision handling of sensitive/high-value products, validation requirements.

- Lifespan Factors: Typically operate in very clean, controlled environments, minimizing external wear factors. Emphasis on smooth, precise operation. Often achieve long lifespans due to stringent maintenance protocols and less harsh physical conditions. Stainless steel construction is common.

4. Manufacturing and Heavy Industry

- Demands: Handling heavy, potentially abrasive or uneven loads (castings, raw materials). Exposure to dust, debris, oils, chemicals, and potential impacts.

- Lifespan Factors: These environments are often the most challenging. Shorter lifespans can occur unless heavy-duty models specifically designed for rugged use are selected. Reinforced frames, guarding, and robust power systems are crucial. Maintenance is critical to combat environmental factors.

Total Cost of Ownership (TCO) vs. Lifespan

Evaluating a pallet inverter solely on purchase price is misleading. A comprehensive Total Cost of Ownership (TCO) analysis provides a clearer picture of long-term value:

- TCO Calculation: TCO = Initial Purchase Price + Installation Costs + Energy Costs + Maintenance Expenses (parts, labor) + Downtime Costs + Operator Costs - Residual/Resale Value.

- Lifespan Impact: A model with a longer lifespan typically incurs lower lifetime maintenance costs and significantly reduces downtime costs. While the initial price might be higher, these savings often lead to a lower overall TCO. Conversely, a cheap inverter needing replacement every 5-7 years will likely have a much higher TCO than a quality model lasting 10-15+ years. Investing in durability is often the most cost-effective strategy over the equipment's life cycle.

Key Considerations When Choosing a Long-Lasting Pallet Inverter

To maximize your investment and ensure longevity, prioritize these factors during selection:

- Assess Your Application: Honestly evaluate your load types, weights, frequency of use (cycles per day/shift), and operating environment (temperature, cleanliness, potential contaminants).

- Prioritize Build Quality:

- Material Composition: Insist on heavy-gauge steel frames and robust components. Ask about material specifications.

- Construction: Examine weld quality, component protection, and overall fit and finish.

- Match Duty Cycle: Select a model rated for your usage intensity (light, medium, heavy-duty). Don't underspecify to save initial cost.

- Evaluate Maintenance Requirements: Understand the recommended maintenance schedule. Opt for models with accessible service points and readily available spare parts. Consider manufacturer support and service availability.

- Consider Environmental Needs: If operating in harsh conditions (washdown, cold, dust), choose models specifically designed or treated for those environments (e.g., stainless steel, galvanized, sealed bearings).

- Review Manufacturer Reputation: Look for manufacturers with a proven track record for building durable, reliable equipment and offering good post-sales support.

pallet changer heavy load (4) Conclusion

Selecting a pallet inverter that offers a long operational lifespan is crucial for efficient, cost-effective material handling. While factors like initial cost are important, focusing on build quality, matching the machine to the application intensity and environment, and committing to regular maintenance are key to achieving longevity.

Durable models, often characterized by heavy-duty construction and high-quality components, may require a higher upfront investment but typically yield a lower Total Cost of Ownership through reduced maintenance costs, minimized downtime, and an extended service life. By carefully evaluating the factors discussed – from material specifications and usage demands to environmental conditions and maintenance protocols – you can choose a pallet inverter that provides long-lasting performance and delivers significant value to your operation for many years.

Get Your Best Solution !