Understanding Automatic Coiling Machines for Pipe and Hose Production

An automatic coiling machine serves as crucial downstream equipment, often integrated directly with an extrusion line, to efficiently manage and coil continuous lengths of pipe and hose. These systems automate a traditionally labor-intensive process, enhancing productivity and consistency in manufacturing environments.

How Automatic Coilers Operate

Typically positioned after the extruder's cooling tanks and puller units, the coiling machine receives the continuous pipe or hose. Its core operation involves:

- Feeding: The material is guided into the coiling mechanism.

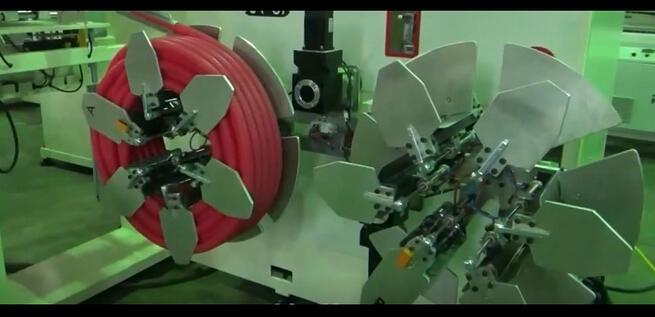

- Coiling: A rotating frame or mandrel, powered by motorized drives, winds the pipe or hose into a coil of a predetermined size. Guides and rollers ensure the material lays evenly.

- Tension Control: Mechanisms maintain consistent tension during winding to prevent slackness or excessive stretching, ensuring a tight, stable coil.

- Cutting: Once the desired length or coil size is reached, an integrated cutter automatically severs the pipe or hose.

- Discharge/Handling: The finished coil is often automatically ejected or moved to a strapping/packaging station or a collection area.

Seamless Integration with Extrusion Lines

A key function of these machines is their ability to synchronize speed with the upstream extrusion line. This ensures the coiler matches the output rate of the extruder, preventing material build-up or tension issues between the processes. This integration is vital for continuous, uninterrupted production runs.

Key Operational Features and Adjustability

Modern automatic coiling machines offer significant flexibility:

- Variable Coil Diameter: Operators can precisely set the inner and outer diameter of the coil according to specific requirements.

- Adjustable Coiling Speed: The winding speed can be synchronized with the extrusion line speed.

- Tension Control Settings: Allows fine-tuning of winding tension suitable for different material types, sizes, and flexibility (e.g., rigid PVC pipe vs. flexible rubber hose).

- Material Compatibility: Designed to handle a wide range of materials (PVC, PE, PEX, rubber, composite) and dimensions (diameters and wall thicknesses).

- Programmable Length: Coil length can be set accurately via the control interface.

Control Systems: PLC and HMI

Operations are typically managed through Programmable Logic Controllers (PLCs) coupled with Human-Machine Interfaces (HMIs). This combination provides:

- Process Automation: Full control over coiling cycles, speeds, lengths, and tension.

- Parameter Adjustment: Easy setting and modification of operational parameters via touchscreen or button interfaces.

- Monitoring & Diagnostics: Real-time feedback on the coiling process and system status, including fault diagnostics.

- Recipe Management: Storage of settings for different product types, facilitating quick changeovers.

Essential Safety Mechanisms

Safety is paramount in automated systems. Common features include:

- Jam Detection: Sensors detect tangles or obstructions, halting the machine to prevent material damage or equipment failure.

- Emergency Stops: Easily accessible E-stops allow immediate shutdown.

- Physical Guarding: Protective barriers or enclosures prevent operator access to moving parts during operation.

- Over-Tension Protection: Prevents damage to the pipe/hose or machine if tension exceeds set limits.

Construction and Durability

Built for industrial environments, these machines typically feature robust construction using heavy-gauge steel frames. This ensures stability during high-speed coiling operations and contributes to long service life with minimal maintenance. Components are selected for durability to withstand the stresses of continuous operation.

Core Benefits of Automated Coiling

Implementing an automatic coiling machine offers several advantages:

- Increased Throughput: Continuous, automated operation significantly boosts production output compared to manual coiling.

- Consistent Coil Quality: Ensures uniform coil size, tightness, and appearance, meeting quality standards consistently.

- Improved Operator Safety: Reduces risks associated with manual handling of long, potentially heavy lengths of material.

- Reduced Labor Costs: Frees up personnel from manual coiling tasks, allowing them to focus on other value-added activities.

- Minimized Material Waste: Precise length control and prevention of kinking/crimping reduce scrap.

These machines are indispensable in industries producing large volumes of pipe, hose, tubing, or similar continuous-length products, streamlining the final step before packaging or storage.

More hose and pipe coiling and strapping solution: https://www.fhopepack.com/Automatic-Coiling-Machine/