Play Video about horizontal steel wire packing machinery 2

The Coil Wrapping Machine is sophisticated, ring-type wrapping equipment specifically designed for efficient and secure packaging of coiled products. Utilizing a unique ID through method, this machine ensures consistent wrapping of packing material around the coils, providing unparalleled protection during transportation and storage.

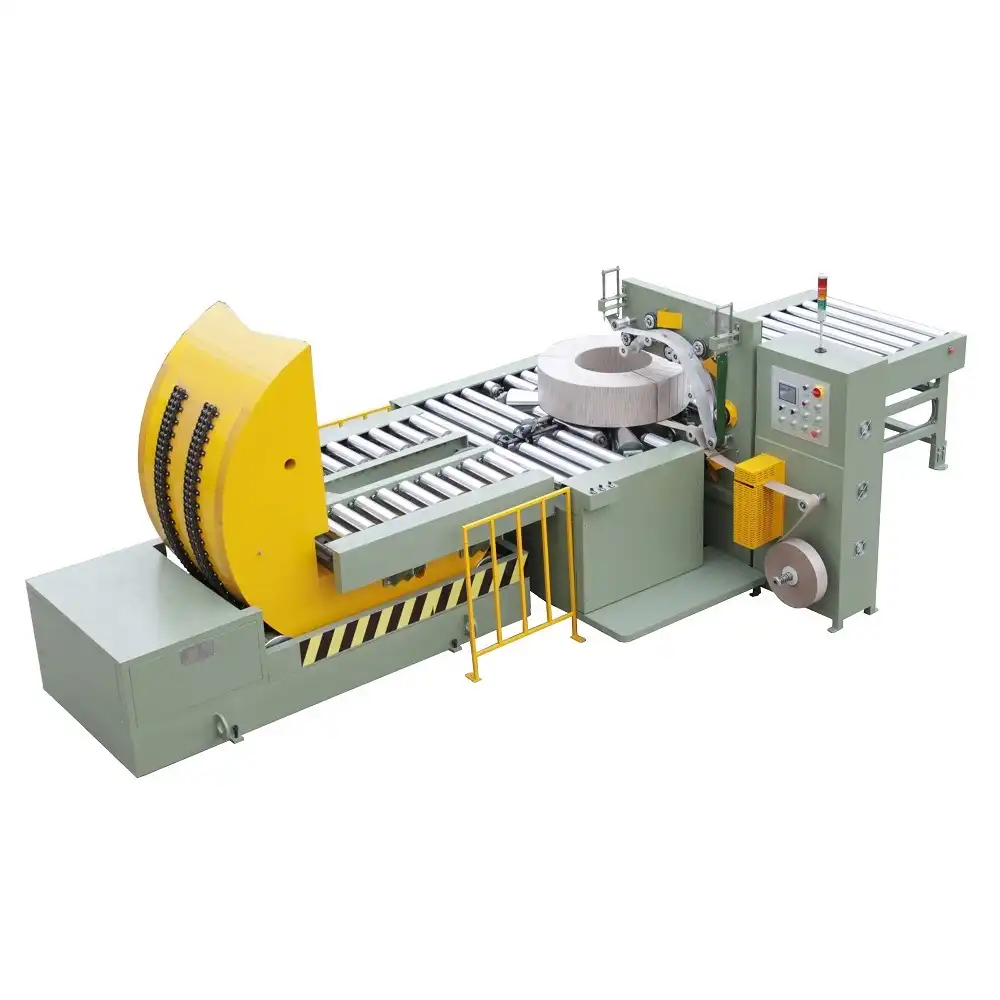

Basice model for light coil wrapping by coil rolling in & out to the wrapping position

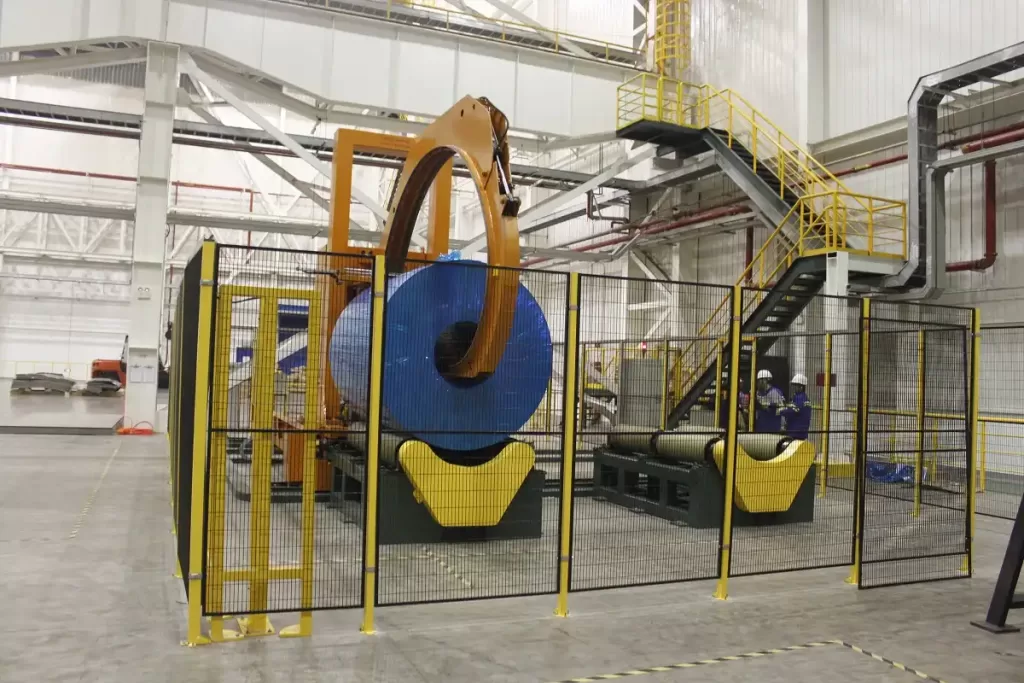

Coil Loading from top by crane, usually for heavy steel coil, wire coil

Trolley for coil moving in and out that is for heavy coil safety operation

Coil loading and unalding by manully or crane. Usually for light, soft and speicl shape product

Conveyor for coil automatic loading, positioning, packing and out-feeding

The autoamtic coil packing line that can be mutifunction for coil handling, labeling, packing, strapping, stacking...

The machine replace the manual packing with 20-60 sec per coil

The operator in the safety area in all packing procession, not injury

One machine replace 3-5 peoples and save packaging material

Better protection for coil by the same packing material than manual

Min.&Max. OD x ID x Width & Weight

Such as: stretch film, paper, knit belt

How many coil need to be packing per hour?

For example: for surface protection, anti-rust,oversea shipping…

The way to loading and unloading the coil such as by crane, conveyor, forklifter…

The space allawance for the machine insation in considering coil handling.

Considering the machine function per future development.

Finding the best solution matching to.

Contact with our team for the reply with detail

A coil wrapping machine is an industrial packing machine designed to package coil-shaped products such as steel coils, wire coils, and hose coils using various packing materials. This machine is essential for providing protective wrapping and ensuring the safe transport and storage of coiled products.

The coil wrapping machine is compatible with a wide range of packing materials, including stretch film, woven fabric, paper, and other specialized materials designed for coil protection. The choice of packing material depends on the product’s requirements and the desired level of protection during transport and storage.

The coil wrapping machine uses a rotating ring mechanism to wrap the packing material around the coil product. The coil is placed on a supporting roller system, and the wrapping material is fed through the rotating ring. As the ring rotates around the coil, the packing material is applied evenly and tightly, providing a secure and protective wrapping.

Yes, coil wrapping machines are typically designed to accommodate a range of coil sizes and dimensions. They can be adjusted to handle various coil diameters, widths, and weights. Some machines also offer customizable options to meet specific requirements or accommodate unique coil shapes.

Using a coil wrapping machine offers several benefits, including:

To choose the right coil wrapping machine, consider the following factors:

The coil wrapping machine is designed to last for many years, with a typical life expectancy of 10-15 years under normal operating conditions and proper maintenance. The actual lifespan may vary depending on usage patterns, environmental conditions, and adherence to recommended maintenance schedules.

We are committed to providing excellent customer support. If the machine experiences any issues, please contact our technical support team immediately. They will help troubleshoot the issue and provide guidance on the necessary steps to resolve it. In case the problem cannot be resolved remotely, we can arrange to dispatch a service technician to your location or provide guidance on finding a qualified local technician. We also offer comprehensive maintenance and service contracts for added peace of mind.

Yes, it is advisable to keep certain spare parts on hand to minimize downtime in case of component failure. We recommend stocking the following parts:

Please consult your machine’s manual or contact our support team for a complete list of recommended spare parts tailored to your specific machine model.

Yes, most coil wrapping machines are designed for ease of use and require minimal operator training. The machine usually features a user-friendly control panel that allows for easy adjustment of settings, such as wrapping speed, tension, and overlap.

Regular maintenance and cleaning of the coil wrapping machine are essential for optimal performance and longevity. Follow the manufacturer’s maintenance guidelines, which typically include:

Manufacturers usually provide after-sales support, including technical assistance, spare parts, and maintenance services. The warranty period and coverage may vary, so it’s essential to confirm these details with the manufacturer.

Yes, many manufacturers offer customizable coil wrapping machines to meet specific requirements or unique coil shapes. Discuss your needs with the manufacturer to determine the best solution for your application.

The cost of a coil wrapping machine depends on factors such as the machine’s size, capacity, features, and level of automation. Prices can range from a few thousand to several tens of thousands of dollars. Contact the manufacturer or a trading company for a detailed quote based on your specific needs.

Delivery and installation times may vary depending on factors such as the machine’s complexity, customizations, and location. Consult with the our technical team and sales team for a precise timeline.

We understand that every customer’s needs are unique, and we are more than willing to work with you to develop a customized solution for your coil wrapping requirements. Our engineering team will collaborate with you to understand your specific needs and design a tailored solution that meets your requirements. Please contact our sales team to discuss your customization needs and receive a personalized quote.

By providing these answers, we hope to address the main concerns of both the middle trading company and the end user, ensuring a smooth and satisfactory experience with our coil wrapping machines.

At Fhopepack, we are a leading manufacturer of ring type coil wrapping machines. Our commitment is to provide high-quality and cost-effective automatic systems, while also offering a wide range of standard wrapping machinery for quick delivery. Our heavy-duty constructions, dual-column designs, and customized equipment with low maintenance are just some of the hallmarks of the Fhopepack machinery line.

We specialize in providing coil wrapping and packing solutions, and our success lies in our ability to design and manufacture customized equipment according to our clients’ specifications. Our ongoing commitment is to provide innovative long-term solutions that allow coil processors to consistently produce high-quality and cost-effective packaging for their end-users.

Projects Completed

Happy Customers

Awards Patent

Years In Service

Our team will reply your massage in 24 hours.