Coil Upenders: A Detailed Comparison of Essential Features Across Various Models

Introduction

Coil upenders are essential equipment in various industrial settings, particularly in the metal processing and manufacturing sectors. These machines are designed to efficiently and safely handle coils of steel, aluminum, and other materials, making the process of loading and unloading much easier. With several models available in the market, it is crucial to understand the key features and differences between them to make an informed decision when investing in a coil upender. In this comprehensive article, we will explore the various aspects of coil upenders and compare the key features across different models.

What are Coil Upenders?

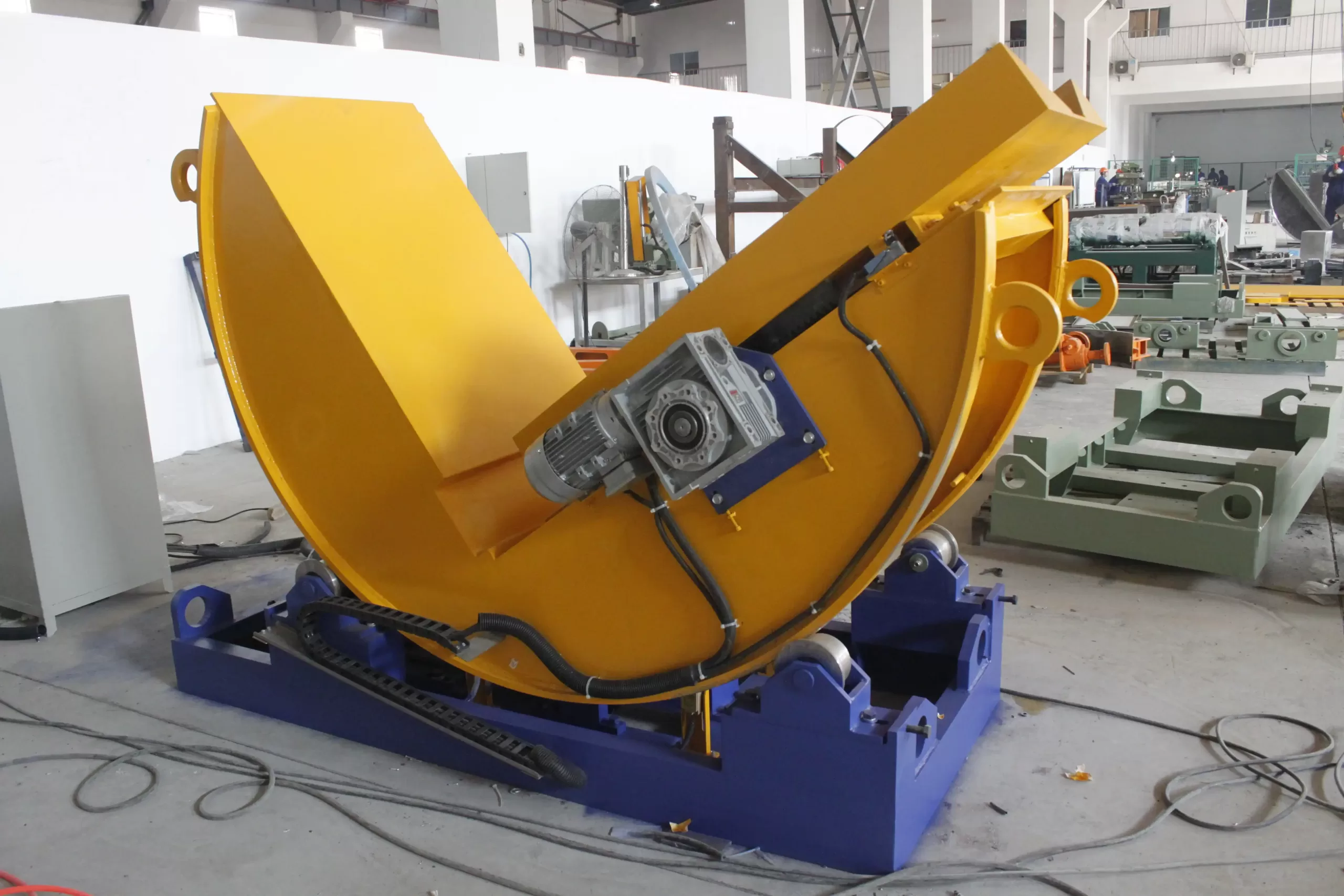

Coil upenders are specialized machines that are used to rotate coils of material, such as steel or aluminum, from a horizontal to a vertical position, or vice versa. This process is essential for loading and unloading coils onto and from processing lines, storage racks, or transportation vehicles. Coil upenders come in various sizes and capacities, depending on the weight and dimensions of the coils they are designed to handle.

Key Components of Coil Upenders

To understand the differences between coil upender models, it is essential to familiarize oneself with the key components that make up these machines. The main components of a coil upender include:

- Frame: The frame is the main structure of the coil upender, providing support and stability to the entire machine.

- Cradle: The cradle is the part of the upender that holds the coil during the rotating process. It is designed to accommodate coils of various sizes and weights.

- Drive System: The drive system is responsible for rotating the cradle and the coil. It typically consists of an electric motor, gearbox, and chains or belts.

- Control System: The control system allows operators to manage the upender's functions, such as rotation speed, direction, and positioning.

Types of Coil Upenders

There are several types of coil upenders available, each designed to cater to specific industrial needs. The most common types include:

- Standard Coil Upenders: These are the most basic type of upenders, suitable for handling coils of moderate weight and size. They are typically used in smaller manufacturing plants or warehouses.

- Heavy-Duty Coil Upenders: As the name suggests, heavy-duty coil upenders are designed to handle larger and heavier coils. They are built with more robust frames and drive systems to accommodate the increased load.

- Motorized Coil Upenders: Motorized upenders feature an electric drive system that allows for precise control over the rotation speed and positioning of the coil. This type of upender is ideal for applications that require frequent and accurate coil handling.

- Hydraulic Coil Upenders: Hydraulic upenders use a hydraulic drive system to rotate the cradle and the coil. They are known for their high lifting capacity and smooth operation, making them suitable for handling heavy and delicate coils.

Comparing Key Features Across Different Models

When comparing coil upenders, there are several key features to consider. These features can vary significantly across different models, and understanding them is crucial for selecting the right upender for your specific needs.

- Load Capacity: One of the most important factors to consider when choosing a coil upender is its load capacity. Different models are designed to handle coils of varying weights, ranging from a few hundred kilograms to several tons. It is essential to select an upender with a load capacity that matches or exceeds the weight of the coils you intend to handle.

- Coil Size Range: Coil upenders are designed to accommodate coils of specific size ranges. The size range is typically determined by the minimum and maximum inside diameter (ID) and outside diameter (OD) of the coils. When comparing models, ensure that the upender you choose is compatible with the size range of your coils.

- Rotation Speed: The rotation speed of a coil upender determines how quickly it can rotate a coil from a horizontal to a vertical position, or vice versa. Faster rotation speeds can lead to increased productivity, but may also require a more powerful drive system and higher energy consumption. Consider your production requirements and energy efficiency goals when comparing rotation speeds across different models.

- Safety Features: Coil handling can be a hazardous process, and it is crucial to prioritize safety when selecting a coil upender. Look for models that incorporate safety features such as emergency stop buttons, overload protection, and fail-safe brakes. Some advanced models may also include sensors that detect if the coil is properly secured in the cradle before initiating rotation.

- Ease of Operation: The ease of operation is another essential factor to consider when comparing coil upenders. Look for models with user-friendly control panels and intuitive interfaces that allow operators to control the upender's functions easily. Some models may also feature remote control capabilities, enabling operators to control the upender from a safe distance.

- Maintenance Requirements: Like any other industrial equipment, coil upenders require regular maintenance to ensure optimal performance and longevity. When comparing different models, consider the maintenance requirements of each one. Some models may have more complex drive systems or hydraulic components that require specialized maintenance, while others may have simpler designs that are easier to maintain. Consider the availability of spare parts and the ease of accessing critical components for maintenance purposes.

- Customization Options: Depending on your specific industrial needs, you may require a coil upender with customized features. Some manufacturers offer customization options, such as modified cradle designs, additional safety features, or integration with other equipment. When comparing models, inquire about the manufacturer's ability to customize the upender to suit your unique requirements.

- Energy Efficiency: Energy efficiency is an increasingly important factor to consider when selecting industrial equipment. Coil upenders with more efficient drive systems and optimized designs can help reduce energy consumption and operating costs. Look for models that incorporate energy-saving features, such as regenerative braking or variable frequency drives, which can help minimize energy waste during operation.

- Durability and Reliability: Coil upenders are subjected to significant stress and wear during operation, and it is essential to choose a model that is built to last. When comparing different models, consider the quality of the materials used in construction, such as the strength of the steel frame and the durability of the drive components. Look for models with proven track records of reliability and longevity in industrial settings similar to your own.

- Cost and Return on Investment: Finally, cost is always a critical factor when investing in industrial equipment. Coil upenders can vary significantly in price, depending on their size, capacity, and features. However, it is important to consider the long-term return on investment when comparing models. A higher-priced upender with advanced features and better energy efficiency may ultimately provide a better return on investment through increased productivity, reduced maintenance costs, and lower operating expenses over time.

Real-World Applications of Coil Upenders

Coil upenders are used in a wide range of industries and applications, demonstrating their versatility and importance in modern manufacturing and material handling processes. Some of the most common applications include:

- Steel Mills: In steel mills, coil upenders are used to handle large coils of steel sheet or plate, allowing for efficient loading and unloading of processing lines and storage racks.

- Aluminum Processing: Coil upenders are also widely used in aluminum processing plants, where they are employed to handle coils of aluminum sheet, foil, and plate.

- Copper and Brass Mills: In copper and brass mills, coil upenders are used to handle coils of copper and brass sheet, strip, and tube, facilitating efficient processing and storage.

- Packaging Industry: The packaging industry relies on coil upenders to handle large rolls of paper, plastic film, and foil, which are used in the production of various packaging materials.

- Textile Industry: Coil upenders are used in the textile industry to handle large rolls of fabric, allowing for efficient loading and unloading of processing equipment and storage systems.

Conclusion

Coil upenders are critical components in various industrial settings, enabling the efficient and safe handling of coiled materials. When comparing different coil upender models, it is essential to consider key features such as load capacity, coil size range, rotation speed, safety features, ease of operation, maintenance requirements, customization options, energy efficiency, durability, and cost. By carefully evaluating these factors and understanding the specific needs of your industry and application, you can select the best coil upender model to optimize your material handling processes, increase productivity, and ensure a strong return on investment. As technology continues to advance, manufacturers are likely to develop even more innovative and efficient coil upender designs, further enhancing their performance and versatility in a wide range of industrial applications.

Get Your Best Solution !