Optimizing Your Packaging Line: Why More Automation in Orbital Wrappers Matters

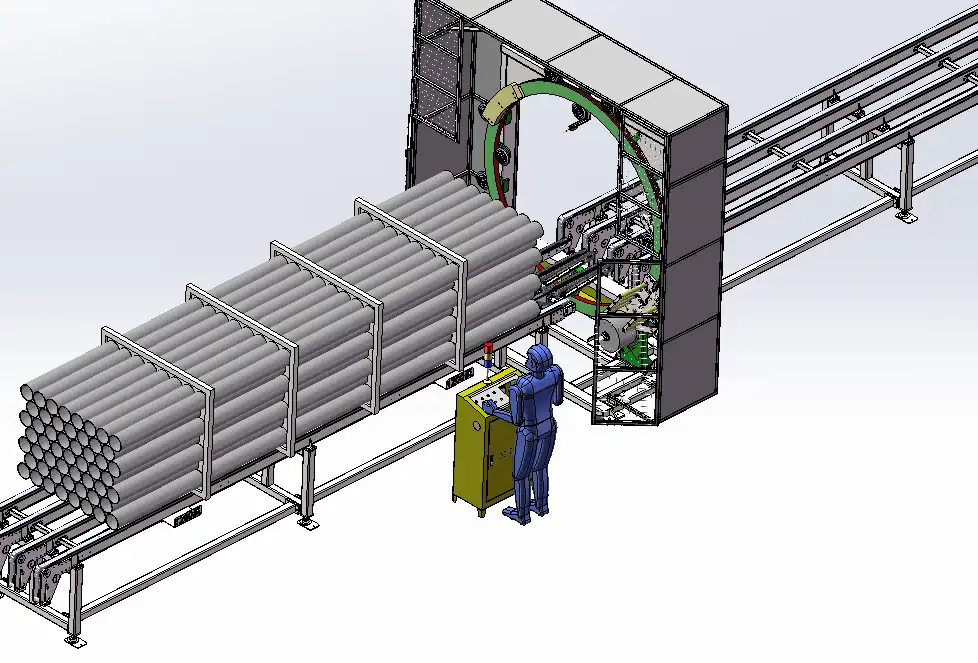

Automation is reshaping manufacturing and logistics, with packaging operations at the forefront of this transformation. Advanced orbital wrapping machines, equipped with multiple automatic functions, empower businesses to significantly enhance efficiency, control costs, and streamline workflows. Investing in such a machine isn't just about automating a single step; it’s about maximizing the number of automated tasks the equipment handles. The greater the degree of automation, the higher the potential for productivity gains.

This guide explores the critical reasons why selecting an orbital wrapping machine with the maximum feasible auto functions is a strategic advantage. From reducing long-term labor expenditures to ensuring consistent packaging quality, increased automation delivers substantial benefits. Let's examine these advantages and understand how adopting comprehensive automation can elevate your operational performance.

1. Understanding the Cost Equation: Automation vs. Manual Labor

A primary driver for adopting automation is the long-term economic benefit. While the initial capital expenditure for a feature-rich orbital wrapping machine can be significant, it represents a largely fixed investment compared to the variable and often increasing costs associated with manual labor.

A. The Economic Case for Automated Wrapping

Automated systems operate consistently without fatigue, breaks, or shift changes, maintaining peak performance levels essential for high-volume environments. This contrasts with manual operations where productivity can fluctuate. Key economic advantages include:

- Reduced Labor Dependence: Lowers direct labor costs and associated overheads (training, benefits, etc.).

- Predictable Operating Costs: Machine running costs (energy, maintenance) are generally more predictable than fluctuating labor expenses.

- Optimized Material Usage: Automated control over film tension and application can reduce film consumption and waste compared to manual wrapping.

B. Strategic Investment for Long-Term ROI

Although a basic orbital wrapper has a lower upfront cost, a model with extensive auto functions often delivers a superior return on investment (ROI). The initial outlay is offset over time by significant savings in labor, reduced product damage due to consistent wrapping, and minimized material waste. This makes investing in higher automation a sound financial strategy for forward-thinking businesses.

2. Boosting Operational Efficiency Through Automation

Maximizing the utility of an orbital wrapping machine involves selecting a model integrating numerous automated functions. Each task the machine performs autonomously—from film attachment and cutting to cycle initiation—directly translates into saved time and labor, minimizing bottlenecks and increasing throughput.

A. Minimizing Operator Intervention in Repetitive Tasks

Operators often dedicate considerable time to routine actions like manually attaching film to the load, cutting the film post-wrap, and initiating each cycle. Automated features perform these tasks efficiently and consistently:

- Auto Film Attach/Cut/Press: Eliminates manual handling of the film at the start and end of cycles.

- Automatic Cycle Start: Reduces delays between loads.

B. Streamlining the Entire Wrapping Workflow

By automating multiple sequential functions, you create a fluid and continuous wrapping process. This minimizes interruptions, reduces cycle times, and ensures a smoother production flow. A machine capable of handling the entire wrap cycle without manual intervention significantly cuts down on non-productive time, boosting overall equipment effectiveness (OEE).

3. Redeploying Your Workforce: Focusing on Value-Added Tasks

Automating routine packaging tasks frees up valuable human resources to concentrate on more complex and impactful activities. Instead of manually wrapping loads, operators can shift their focus to areas requiring critical thinking and expertise.

A. Elevating Workforce Contribution

With automation handling the repetitive aspects of wrapping, your team can be strategically redeployed to:

- Oversee multiple automated lines.

- Perform quality control checks.

- Manage inventory and logistics coordination.

- Engage in preventative maintenance.

- Participate in process improvement initiatives.

B. Improving Workplace Safety and Ergonomics

Manually wrapping, especially large or heavy loads, involves repetitive motions and awkward postures that can lead to operator fatigue, errors, and potential musculoskeletal injuries. Automating these functions enhances operator safety and reduces physical strain, contributing to a healthier and more focused workforce.

4. Key Feature: Automated Film Cutting for Seamless Operation

One of the most impactful auto functions is automatic film cutting. Upon cycle completion, the machine cleanly cuts the stretch film, preparing the load for removal and the machine for the next cycle without operator involvement.

A. Enabling Uninterrupted Material Handling

With automatic film cutting and holding mechanisms (like film clamping or wiping), forklift operators often don't need to dismount to handle the film tail. This saves critical seconds per cycle, reduces physical effort, and allows the operator to immediately transport the wrapped load and retrieve the next one, keeping the material flow consistent.

B. Enhancing Safety and Cut Consistency

Automated cutting removes the need for operators to use manual cutting tools near the machinery or the load, reducing the risk of cuts or other accidents. Furthermore, automated systems provide a consistent, clean cut, minimizing long film tails that could interfere with handling equipment or scanning systems.

5. Key Feature: Auto-Start and Remote Operation Capabilities

The auto-start function, often combined with remote operation, allows the wrapping cycle to begin automatically or via remote signal, eliminating the need for the operator to physically interact with the machine's control panel for each load.

A. Convenient Remote Cycle Initiation

Modern orbital wrappers can often be initiated remotely:

- Pull Cord: A simple lanyard switch allows a forklift operator to start the cycle without dismounting.

- Remote Control: A handheld remote provides flexibility for operators managing multiple tasks.

- Photo-Eye Sensors: Detect the presence of a load in the wrap zone and initiate the cycle automatically.

This remote capability keeps operators focused on material handling, maximizing efficiency.

B. Minimizing Transition Time Between Loads

Automated start functions drastically reduce the downtime between wrapping one load and starting the next. In high-throughput operations, shaving seconds off each cycle transition accumulates into significant gains in overall productivity and helps meet demanding production schedules.

6. Integrating Tasks: Weighing and Labeling Automation

Advanced orbital wrapping machines can integrate additional crucial functions like weighing and labeling directly into the wrapping cycle, further consolidating processes and saving valuable time.

A. Integrated Weighing Systems

Incorporating a weigh scale into the wrapping machine allows loads to be accurately weighed during the process.

- Benefits: Eliminates the need for a separate weighing station, saves floor space, reduces handling time, and ensures accurate weight data for shipping manifests and load planning.

B. Automated Label Printing and Application

Machines can be equipped with systems to automatically print and apply labels (shipping info, barcodes, product IDs) as the load exits the wrap zone.

- Benefits: Reduces manual labeling errors, ensures consistent label placement, speeds up package preparation for dispatch, and enables better tracking through the supply chain. Potential for direct integration with Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems for seamless data flow.

C. Multitasking for Peak Throughput

Combining wrapping, weighing, and labeling into one automated sequence maximizes operational efficiency. While the machine completes these tasks, the operator is free to handle the next load, ensuring the packaging line runs at its highest potential capacity.

7. Consolidated Advantages of Maximizing Automation

Opting for an orbital wrapping machine rich in auto functions delivers a wide spectrum of operational improvements:

- Reduced Operating Costs: Lower direct labor expenses, optimized material usage, and potentially lower insurance premiums due to enhanced safety.

- Improved Efficiency & Throughput: Faster cycle times, minimal downtime between loads, and streamlined workflow lead to higher output.

- Enhanced Consistency & Quality: Uniform film application, tension, and containment force ensure every load is wrapped to specification, reducing product damage during transit.

- Increased Safety: Minimizes manual interaction with machinery and reduces ergonomic risks for operators.

- Better Data Accuracy: Integrated weighing and labeling reduce errors associated with manual data entry or separate processes.

- Scalability: Automated systems can more easily handle fluctuations in production volume compared to manual operations.

8. The Evolving Landscape of Packaging Automation

The trend towards automation in packaging continues, driven by technological advancements and the need for greater efficiency and sustainability. Future orbital wrapping machines are likely to become even more integrated and intelligent.

A. Smart Machines: AI, IoT, and Data Analytics

Expect increased integration of:

- Internet of Things (IoT) sensors: Monitoring machine performance, predicting maintenance needs (predictive maintenance), and tracking operational data.

- Artificial Intelligence (AI): Potentially optimizing wrap patterns based on load characteristics detected by sensors.

- Data Analytics: Providing insights into throughput, material consumption, and machine uptime for continuous improvement. Integration with broader Industry 4.0 initiatives and smart factory ecosystems.

B. Automation Driving Sustainability Goals

Automation plays a key role in sustainable packaging:

- Precision Film Application: Applying the right amount of film with the correct tension minimizes material waste.

- Optimized Performance: Efficient operation reduces energy consumption per unit wrapped.

- Data-Driven Insights: Helps identify opportunities to further reduce material usage without compromising load integrity.

Conclusion: Maximize Automation for Maximum Operational Excellence

When selecting an orbital wrapping machine, prioritizing a model with a comprehensive suite of auto functions is a strategic investment in your operational future. Automating tasks such as film management (attach, cut, press), cycle initiation, load weighing, and labeling delivers substantial returns through reduced labor costs, enhanced efficiency, superior consistency, and improved safety.

Investing in advanced automation future-proofs your packaging operations, enabling you to maintain a competitive edge. By minimizing manual touchpoints and maximizing machine capability, businesses can optimize their entire packaging workflow, ensure product protection during transit, and achieve higher levels of productivity and reliability.