When it comes to packaging steel wire, selecting the best packing solution is crucial for ensuring the wire remains secure, protected, and ready for shipping. In this guide, I will break down the top solutions for steel wire packaging, focusing on different types of packaging methods, their effectiveness, and the best solutions available in 2024.

What is Steel Wire Packaging?

Steel wire packaging refers to the process of wrapping, protecting, and securing steel wire coils or bundles for transportation or storage. The goal is to safeguard the wire against environmental damage, like rust or corrosion, while also making the handling, storing, and shipping process easier and more efficient.

Key Factors in Steel Wire Packaging

Before diving into the best packing solutions, let's explore the most critical factors to consider when selecting packaging for steel wire:

- Protection Against Corrosion: Steel wire is highly susceptible to rust, especially during long shipping periods or exposure to moisture. Packaging materials like water-resistant paper or plastic films can provide vital protection.

- Durability and Strength: Steel wire packaging needs to be robust enough to withstand the weight and pressure exerted during transit, particularly when it comes to heavy coils.

- Ease of Handling: The packaging should allow for easy handling and transport, whether the wire is being moved by hand or with machinery like cranes or forklifts.

- Cost-Effectiveness: Finding the balance between protective features and the overall cost of the packaging is key for many businesses.

- Sustainability: As the world becomes more eco-conscious, opting for sustainable materials is gaining importance in the packaging industry.

Top Packing Solutions for Steel Wire in 2024

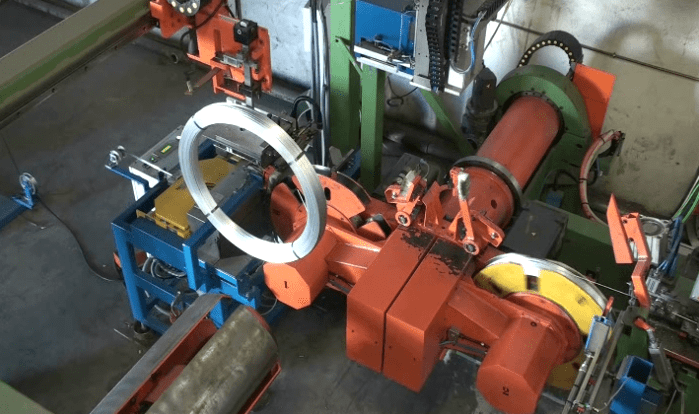

1. Coil Wrapping Machines (Automatic and Industrial Options)

Coil wrapping machines are a game-changer for steel wire packaging, offering automated wrapping solutions that improve efficiency and consistency. These machines are designed to wrap coils of steel wire in materials like polypropylene (PP) and polyethylene (PE), which help protect the wire from rust and damage.

Key Features:

- Speed: Up to 300 coils per hour

- Wire Diameter & Weight: Can handle wire coils up to 10 tons in weight

- Material Compatibility: Compatible with PP/PE films and water-resistant papers

- Automation Level: High automation, reducing labor costs and errors

- Energy Efficiency: Modern machines are designed to reduce power consumption

2. Stretch Film Wrapping

Stretch film wrapping is a highly flexible and cost-effective packing solution for steel wire. The film tightly adheres to the wire coil, providing a snug fit that keeps the wire in place during transport.

Key Features:

- Speed: Can wrap up to 200 coils per hour

- Durability: The stretch film provides excellent tensile strength, ensuring the wire remains secure

- Water Resistance: Protects against moisture and dust

- Cost-Effective: Lower cost than some other packaging methods

- Sustainability: Recyclable films are available, making this option more eco-friendly

3. Steel Banding

Steel banding is one of the most common ways to secure steel wire coils for transport. It involves wrapping a metal strap around the coil to hold it together. This method is especially suitable for heavy-duty wire and is often used for steel wire in industrial settings.

Key Features:

- Strength: Offers superior holding power, ideal for heavy coils

- Safety: The steel band ensures the coil remains intact during rough handling

- Cost: More expensive than plastic alternatives but highly durable

- Environmental Impact: Steel bands are reusable, offering an eco-friendly edge over single-use packaging materials

4. Shrink Wrap

Shrink wrap is an excellent option for steel wire packaging as it provides tight, secure wrapping that conforms to the shape of the wire coil. It is widely used in both industrial and shipping environments.

Key Features:

- Speed: Fast application and shrinkage process

- Durability: Offers a tight seal and exceptional protection against moisture, dust, and damage

- Cost-Effective: Affordable compared to other materials

- Sustainability: Available in eco-friendly materials, though not as sustainable as stretch films

5. Wooden Crates or Pallets

For bulkier or oversized steel wire coils, wooden crates or pallets can provide additional protection. The crates are built to withstand rough handling during shipping and are designed to keep multiple coils secure and organized.

Key Features:

- Strength: Provides a solid base for heavy steel wire

- Protection: Offers superior protection from external forces like pressure or impact

- Versatility: Can be customized to fit specific coil sizes or quantities

- Eco-Friendly: Wood is a renewable resource, and pallets can often be reused or recycled

Comparison of Steel Wire Packing Solutions

| Packing Solution | Speed (Coils/Hour) | Material Compatibility | Durability | Cost | Sustainability |

|---|---|---|---|---|---|

| Coil Wrapping Machine | 300 | PP/PE Films, Waterproof Paper | High | High | Low (depends on material) |

| Stretch Film Wrapping | 200 | PP/PE Films | Medium-High | Low | Medium (recyclable options) |

| Steel Banding | 100 | Steel | Very High | Medium | High (reusable) |

| Shrink Wrap | 250 | PE, PVC | High | Low | Medium (recyclable options) |

| Wooden Crates | Varies (custom) | Wood | Very High | High | High (reusable) |

How to Choose the Right Steel Wire Packaging

Choosing the best packing solution for your steel wire depends on various factors, including your wire's size, weight, shipping destination, and budget. If you are dealing with large quantities of steel wire, you may benefit from industrial packaging solutions like coil wrapping machines. For smaller quantities or tighter budgets, stretch film or shrink wrap might be a better fit. If the wire is particularly heavy or needs extra protection, consider steel banding or wooden crates.

Key Considerations When Choosing:

- Coil Size & Weight: Ensure that the packaging solution can handle the specific dimensions and weight of your steel wire coils.

- Environmental Conditions: Consider the shipping environment. If the coils will be exposed to moisture or extreme weather, opt for water-resistant materials.

- Budget: While it’s important to prioritize protection, you also want a solution that aligns with your budget.

- Automation vs. Manual Handling: Automated solutions like coil wrapping machines save time and labor costs, but manual solutions may be sufficient for smaller operations.

Conclusion

In conclusion, there are many options available for steel wire packaging, each with its strengths and trade-offs. Automated machines, like coil wrapping machines, offer the most efficiency and protection, especially for large-scale operations. However, for smaller batches, more manual solutions like stretch films and steel banding may be sufficient. Ultimately, the right packing solution depends on your unique requirements, including cost, environmental conditions, and wire specifications.

For a comprehensive understanding of packaging materials and methods, visit our Packaging Materials Selection Guide. Additionally, we recommend referencing the ASTM Packaging Standards for industry-specific insights and regulations.