When it comes to packing cable wires, it’s crucial to select the right packaging solution to ensure the wires are protected from damage during transit and storage. The right packaging can also help in maintaining the quality of the cables, especially for long-term storage or shipping over long distances. In this guide, I will explore the best packing solutions for cable wires in 2025, focusing on different methods, their key features, and how to choose the right one for your specific needs.

What is Cable Wire Packaging?

Cable wire packaging involves wrapping, securing, and protecting cables to keep them intact and functional during transit or storage. This process aims to prevent physical damage to the cables, avoid corrosion or moisture exposure, and make the handling and transportation process more efficient. Depending on the type of cable, packaging can vary from simple plastic wraps to more complex solutions such as coil wrapping machines.

Key Factors to Consider When Choosing Cable Wire Packaging

Before diving into the best solutions, it’s important to consider a few key factors that impact your decision:

- Protection Against Damage: Cables can be easily damaged during shipping if not properly packaged. Proper packaging protects the wire from abrasions, punctures, and pressure.

- Protection from Corrosion: Cables, especially those made from metal, are vulnerable to corrosion if exposed to moisture. Packaging materials must be moisture-resistant or waterproof.

- Cost-Effectiveness: While protective packaging is crucial, it’s also important to consider the overall cost of the packaging materials and processes.

- Handling and Transportation: The packaging must be easy to handle and transport, whether by hand, forklift, or automated machinery.

- Environmental Impact: Opting for sustainable or recyclable materials is becoming increasingly important as businesses strive to reduce their environmental footprint.

Top Packing Solutions for Cable Wire in 2024

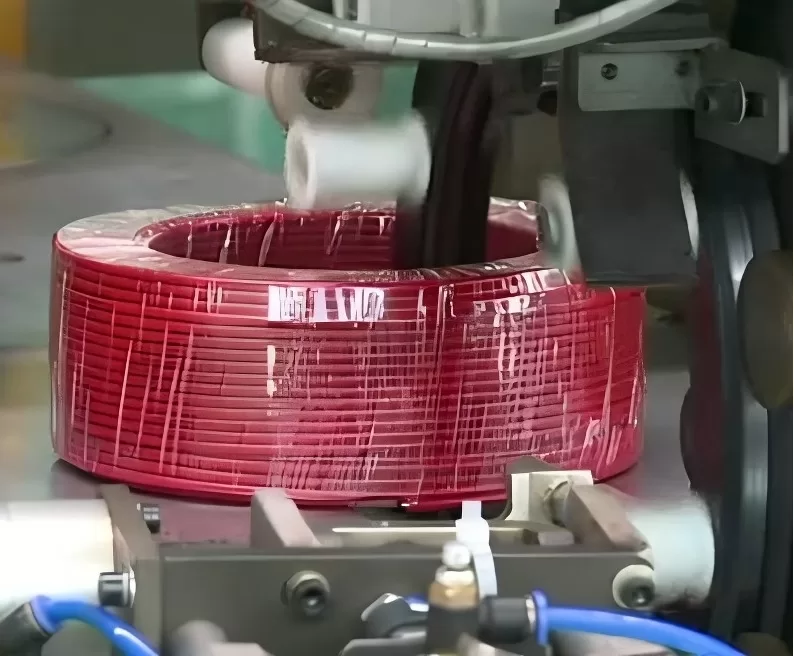

1. Coil Wrapping Machines (Automatic and Industrial Options)

Coil wrapping machines are some of the best solutions for large-scale cable wire packaging. These machines are designed to wrap cables in protective films, providing tight, secure wrapping that prevents damage during transportation. Automatic machines also reduce the need for manual labor, making the process faster and more efficient.

Key Features:

- Speed: Can wrap up to 300 coils per hour, depending on the machine and wire size

- Wire Diameter & Weight: Suitable for handling cable coils of varying sizes and weights, from small rolls to larger industrial coils

- Material Compatibility: Can wrap cables in polypropylene (PP), polyethylene (PE), and water-resistant papers, which help protect the wire from moisture

- Automation Level: High automation for efficient and consistent wrapping

- Energy Efficiency: Modern coil wrapping machines are designed to minimize energy usage

2. Stretch Film Wrapping

Stretch film wrapping is a popular and cost-effective method for packaging cable wires. The film is applied tightly around the cable coils, offering a secure hold and protection. Stretch film is commonly used for smaller batches of cables and provides a flexible, reusable option.

Key Features:

- Speed: Wraps up to 200 coils per hour depending on the size

- Durability: Provides a secure and tight fit that holds cables in place and prevents damage during transportation

- Water Resistance: Protects cables from moisture and dust

- Cost-Effective: Stretch film is one of the most affordable packaging options

- Sustainability: Available in recyclable options, making it a more eco-friendly choice

3. Steel Banding

Steel banding is a highly durable and effective way to secure heavy cable coils. The steel straps provide a strong, secure hold, making it ideal for shipping larger cable coils that require additional stability during transit.

Key Features:

- Strength: Provides superior holding power, ensuring that heavy cable coils remain secure

- Safety: Helps prevent the cable from unrolling or shifting during transit

- Cost: Steel banding is more expensive than plastic alternatives but is a highly durable and reliable option

- Environmental Impact: Steel bands can be reused, making them a more sustainable option compared to single-use packaging materials

4. Shrink Wrap

Shrink wrap is another highly effective option for securing cable wires. When applied, the shrink wrap tightly adheres to the cables, offering excellent protection against dust, moisture, and damage from rough handling.

Key Features:

- Speed: Shrink wrap can quickly and effectively wrap cables

- Durability: Provides a strong, tight seal that helps protect cables from damage and exposure to the elements

- Cost-Effective: Shrink wrap is relatively inexpensive compared to some other packaging materials

- Sustainability: Shrink wrap is available in recyclable materials, though it is less eco-friendly than some other options

5. Wooden Pallets or Crates

For bulkier or larger cable coils, wooden pallets or crates can provide extra protection and stability. Pallets are useful for organizing and securing multiple cable coils in a single shipment, while crates offer protection from impacts or rough handling.

Key Features:

- Strength: Offers robust protection for heavy cable coils

- Protection: Provides additional protection from external impacts during transportation

- Cost: Wooden pallets or crates are generally more expensive than plastic or film-based packaging solutions

- Eco-Friendly: Wood is a renewable resource, and pallets can often be reused or recycled

Comparison of Cable Wire Packing Solutions

| Packing Solution | Speed (Coils/Hour) | Material Compatibility | Durability | Cost | Sustainability |

|---|---|---|---|---|---|

| Coil Wrapping Machine | 300 | PP/PE Films, Waterproof Paper | High | High | Low (depends on material) |

| Stretch Film Wrapping | 200 | PP/PE Films | Medium-High | Low | Medium (recyclable options) |

| Steel Banding | 100 | Steel | Very High | Medium | High (reusable) |

| Shrink Wrap | 250 | PE, PVC | High | Low | Medium (recyclable options) |

| Wooden Crates | Varies (custom) | Wood | Very High | High | High (reusable) |

How to Choose the Best Packing Solution for Cable Wire

Choosing the best packing solution for your cable wire will depend on several factors, including the wire's size, weight, transportation needs, and environmental conditions. If you’re shipping large quantities of cable, an automated coil wrapping machine could save you both time and labor costs. For smaller batches, stretch film or shrink wrap might be more practical and cost-effective. For larger, heavier cable coils, steel banding or wooden crates will provide the extra strength needed.

Key Considerations When Choosing:

- Coil Size & Weight: The packaging should be able to accommodate the specific dimensions and weight of the cable coils.

- Environmental Conditions: If the cable will be exposed to harsh weather or moisture during transportation, choose a waterproof or moisture-resistant solution.

- Budget: Consider your budget when choosing packaging. While protection is key, you also want to avoid overspending.

- Handling & Transport: Think about how the packaging will be handled during transport. If your cables need to be stacked or moved with machinery, choose a solution that makes handling easier.

Conclusion: Best Packing Solution for Cable Wire

Choosing the right packing solution for cable wires depends on your specific needs, such as the wire's size, shipping conditions, and budget. Each solution offers different benefits depending on the scale and type of cables you are dealing with. Below is a summary to help you make an informed decision:

- Coil Wrapping Machines are the most efficient and scalable solution for large volumes of cable wire. They provide high-speed packaging with automated wrapping, reducing labor costs while ensuring the wires are tightly secured and protected.

- Stretch Film Wrapping offers a cost-effective and flexible solution, especially for smaller batches or lower-budget operations. The material is easy to apply, and it provides moisture protection, although it may not be as durable for heavy-duty shipping.

- Steel Banding is ideal for securing heavy coils of wire that need extra strength. While more expensive than plastic alternatives, it is durable, reusable, and can handle the stress of tough transport conditions.

- Shrink Wrap delivers excellent protection against dust, moisture, and handling damage. It’s quick to apply and a more affordable option compared to others, but it doesn’t provide the same strength as steel banding for larger coils.

- Wooden Pallets or Crates offer robust protection for bulkier and heavier wire coils. They provide an organized and secure method of shipping, although they come at a higher cost and may not be necessary for smaller shipments.

Ultimately, the best packing solution for your cable wire will depend on your budget, the type of wire you're shipping, and the level of protection you need. It’s important to balance cost, efficiency, and durability when choosing the most suitable option.

Where to Find More Information on Cable Wire Packaging

For more detailed information on packaging materials and the latest innovations in the industry, I recommend visiting our Packaging Materials Selection Guide. Additionally, for industry-specific standards and regulations, you can refer to documents like the ASTM Packaging Standards.

With the right packaging solution, you can ensure your cable wires are safely transported and stored, maintaining their quality and minimizing potential damages during the process. Choose wisely, and keep your cables secure and ready for use in their final destination.