Automatic wire coil winding and strapping machine.

Fhope provides the wire coil rewinding and wire strapping equipment.

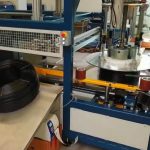

The Automatic Wire Coil Winding and Strapping Machine is specifically tailored for efficiently handling and packaging wire coils. The system incorporates an integrated winding mechanism that precision winds wire into neat coils, followed by an automated strapping unit that securely fastens the coils, ensuring they are compact and stable for storage or shipment. Key features of this machine include precise tension control to prevent wire damage during winding, adjustable coil size settings for versatility, and a robust strapping component that applies uniform pressure to maintain coil integrity. The machine's framework is designed to be durable, operating effectively in industrial environments with minimal maintenance needs.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Fully Automated Coil Winding and Strapping

- Wire Diameter Range: 0.1mm to 10mm

- Coil Inner Diameter: Adjustable, 100mm to 500mm

- Strapping Material: Steel or composite material

- Strapping Thickness: 0.5mm to 1.2mm

- Production Speed: Up to 20 coils per minute

- Power Input: 480V, 60Hz, three phase

- Control System: Advanced PLC with HMI

- Safety Features: Integrated sensors and emergency stops

- Machine Dimensions: Length: 8000mm; Width: 3000mm; Height: 2000mm

- Operator Requirement: Single operator

Applications of the Automatic Wire Coil Winding and Strapping Machine:

- Electrical Component Manufacturing: This machine is ideal for manufacturers of electrical components and cables, where precise and secure winding of wire is crucial. The automated process ensures consistent coil quality, which is essential for the reliability of electrical products.

- Construction and Building: In the construction industry, where large volumes of wiring are needed, this machine enhances the efficiency of preparing coiled wire for various construction purposes. It ensures the coils are tightly wound and strapped, making them easier to handle and install on site.

- Shipping and Handling for Export: This machine is particularly beneficial for companies that distribute wire to international markets. The secure strapping and uniform coil size dramatically reduce the risk of damage during transit and handling, ensuring that the wire arrives in perfect condition, thus reducing complaints and returns.