Automatic steel tube bag packing solution:

It includes the automatic steel tube infeeding ramp, automatic infeeding conveyor, automatic bag packing station, out feeding conveyor. The system controlled by PLC.

PIPE OD:20-60MM speed: 20-50m per minute.

https://www.fhopepack.com

info@fhopepack.com

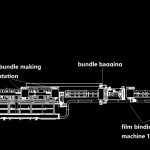

Automatic tube infeeding ramp:

• Holds racks of steel tubes ready for packing

• Feeds tubes onto the infeeding conveyor

Automatic infeeding conveyor:

• Transports tubes from the ramp into the packing station

• Maintains a steady flow of tubes matching the packing speed

Automatic bag packing station:

• Contains bag rolls and a bag opening mechanism

• Has guides that position an open bag below the conveyor

• Features a tube insertion ram or pusher that indexes bags and inserts a tube into each opened bag

• Applies a bag closure (tie wrap, clip or heat seal) after tube insertion

Outfeeding conveyor:

• Removes the packed bags from the packing station

• Transports bags to the discharge point

PLC system:

• Centrally controls the speeds and functions of all components

• Can be programmed to handle different tube OD sizes from 20mm to 60mm

• Set packing speeds of up to 50 meters of tube per minute

Benefits of the automated solution:

• Higher packing outputs achieved through automation

• More consistent packing quality from precision tube insertion and bag sealing

• Reduced manual labor costs

• Easier changeover for different tube sizes via PLC adjustment

So in summary, the automated steel tube bag packing system integrates components to quickly and reliably insert steel tubes ranging from 20mm to 60mm OD into bags at speeds up to 50 meters per minute. The PLC control provides synchronization and flexibility to handle various tube sizes.