info@fhopepack.com

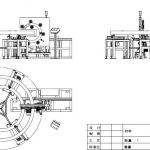

Automatic pipe coilers are machines that are used to coil pipes or tubes automatically. They can handle a wide range of pipe diameters and lengths, and are often used in manufacturing and production facilities. These machines typically have a motorized system that rotates the pipe and feeds it through a coiling head, which forms the pipe into a coil. The resulting coil can then be packaged for shipping or storage.

Film wrapping machines, on the other hand, are used to wrap products in protective film. This can be useful for a variety of applications, including protecting products during shipping, improving their appearance on store shelves, and providing additional protection during storage. Film wrapping machines typically use a roll of plastic film that is fed through the machine, and the product is then wrapped in the film as it passes through the machine.

- Automatic coiling and wrapping: These machines are designed to automatically coil pipes or tubes and wrap them in protective film, eliminating the need for manual labor.

- Adjustable speed and tension: Many machines allow you to adjust the speed and tension of the coiling and wrapping process, which can help ensure a consistent and high-quality result.

- Programmable controls: Some machines have programmable controls that allow you to set specific parameters for the coiling and wrapping process, such as coil diameter, coil length, and wrapping patterns.

There are some machines that combine both functions, and provide automatic coiling and film wrapping capabilities. These machines are often used in industrial settings where pipes or tubes need to be coiled and then wrapped for shipment or storage. They can help improve efficiency and productivity by automating the coiling and wrapping process, reducing the need for manual labor.

There are a wide variety of automatic pipe coilers and film wrapping machines available on the market, ranging from small, tabletop models to large, industrial-scale machines. The specific features and capabilities of each machine will depend on the manufacturer and model, so it’s important to research different options and choose one that best fits your specific needs and requirements.