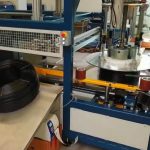

Automatic pipe coile winding machine with packing machine

From Short-Term Costs to Long-Term Gains: Why an Automatic Pipe Coil Packing Line is the Right Choice

Investing in an automatic pipe coil packing line can seem daunting due to initial costs. However, the long-term benefits far outweigh these expenses. In this article, we’ll explore why automating your pipe coil packing process can transform your operations and drive profitability.

Understanding Automatic Pipe Coil Packing Lines

Automatic pipe coil packing lines are designed to efficiently bundle and package coiled pipes. This automation enhances consistency, reduces manual labor, and improves overall productivity.

Initial Investment Costs

Equipment and Installation

The first step in automation involves purchasing and installing specialized machinery. While this requires a significant upfront investment, these machines are built for durability and efficiency, ensuring they serve your business for years.

Training and Adaptation

Training staff to operate new machinery is essential. This initial phase includes learning new processes and adapting to changes, which can incur additional costs but is crucial for maximizing the benefits of automation.

Benefits of Automating the Packing Process

Increased Efficiency and Throughput

Automated systems significantly boost efficiency, allowing for faster packing compared to manual methods. This increased throughput means more products can be processed in less time, meeting higher demand without sacrificing quality.

Consistency and Quality Assurance

Automation ensures consistent packaging quality. Machines operate with precision, reducing human error and ensuring that each coil is packed to exact specifications. This consistency improves product reliability and customer satisfaction.

Labor Cost Reduction

Minimizing Manual Labor

By reducing the need for manual intervention, automation directly lowers labor costs. Employees can focus on more strategic tasks, enhancing overall productivity and job satisfaction.

Enhanced Worker Safety

Automation reduces the physical demands on workers, minimizing the risk of injury. This improvement leads to fewer accidents, lower insurance costs, and a safer work environment.

Long-Term Cost Savings

Material Optimization

Automated systems optimize material usage, minimizing waste. This efficiency not only reduces costs but also supports sustainability efforts by conserving resources.

Energy Efficiency

Modern packing lines are designed to be energy-efficient, reducing power consumption and lowering utility bills. This energy-saving aspect contributes to long-term financial savings and environmental responsibility.

Integration with Smart Technology

Real-Time Monitoring and Control

Smart technology integration allows for real-time monitoring and control of the packing process. This capability provides valuable insights into performance, helping identify areas for improvement and ensuring optimal efficiency.

Predictive Maintenance

IoT-enabled machines offer predictive maintenance features, alerting operators to potential issues before they cause downtime. This proactive approach reduces repair costs and ensures continuous operation.

Environmental Impact

Sustainable Practices

Automating the packing process supports sustainable practices by reducing waste and energy usage. This alignment with green initiatives enhances a company’s environmental reputation and contributes to global sustainability goals.

Reduction in Carbon Footprint

Energy-efficient machines help lower the overall carbon footprint, supporting efforts to combat climate change and promoting a healthier planet.

Challenges and Considerations

Initial Financial Outlay

Although automation offers long-term savings, the initial financial outlay can be substantial. Businesses need to carefully assess their budgets and financial strategies before making the investment.

Adapting to Technological Change

Transitioning to automation requires a cultural shift within the organization. Employees need time to adapt to new technologies and workflows, which can initially slow down operations.

Keeping Up with Technological Advances

Staying competitive means continuously updating systems to incorporate the latest advancements. Businesses must be prepared to invest in ongoing improvements to maintain their edge.

Real-World Success Stories

Manufacturing Efficiency

A major manufacturer implemented automated packing lines, achieving a 35% increase in efficiency and a 25% reduction in labor costs. These changes allowed the company to meet growing demand while maintaining high-quality standards.

Logistics Optimization

In the logistics sector, companies have seen a drastic reduction in errors and improved delivery times after automating their packing processes. The investment paid off within three years, highlighting the financial and operational benefits of automation.

Future Trends in Packing Automation

AI and Machine Learning

The integration of AI and machine learning in packing systems promises even greater efficiency and adaptability. These technologies enable machines to learn from data, optimizing processes in real-time and predicting future trends.

Enhanced Customization

Future packing systems will offer greater customization, allowing businesses to tailor processes to specific needs and customer preferences, further enhancing operational efficiency and customer satisfaction.

Conclusion

In conclusion, investing in an automatic pipe coil packing line is a strategic decision that offers substantial long-term gains. While the initial costs may be significant, the benefits—ranging from increased efficiency and consistency to reduced labor and material costs—make it a worthwhile investment. By embracing automation, businesses not only improve their bottom line but also position themselves for sustainable growth and success. In a competitive market, the right technology can be the key to unlocking new opportunities and achieving lasting success.