Understanding Automatic Pallet Wrapping Machines with Top Sheet Dispensers

Automated packaging lines rely on efficiency and product integrity. For palletized goods requiring protection from environmental factors like dust and moisture, an automatic pallet wrapping machine equipped with a top sheet covering device offers a comprehensive solution. This equipment enhances standard stretch wrapping by applying a protective layer to the top of the load before the main wrapping cycle begins, ensuring full encapsulation.

Operational Workflow and Key Components

An automatic pallet wrapper with a top sheet dispenser integrates several key functions into a seamless process:

- Pallet Entry: The loaded pallet is conveyed into the wrapping station.

- Top Sheet Application: An integrated dispenser automatically positions and cuts a sheet of film (typically polyethylene) to the correct size and drapes it over the top of the pallet load.

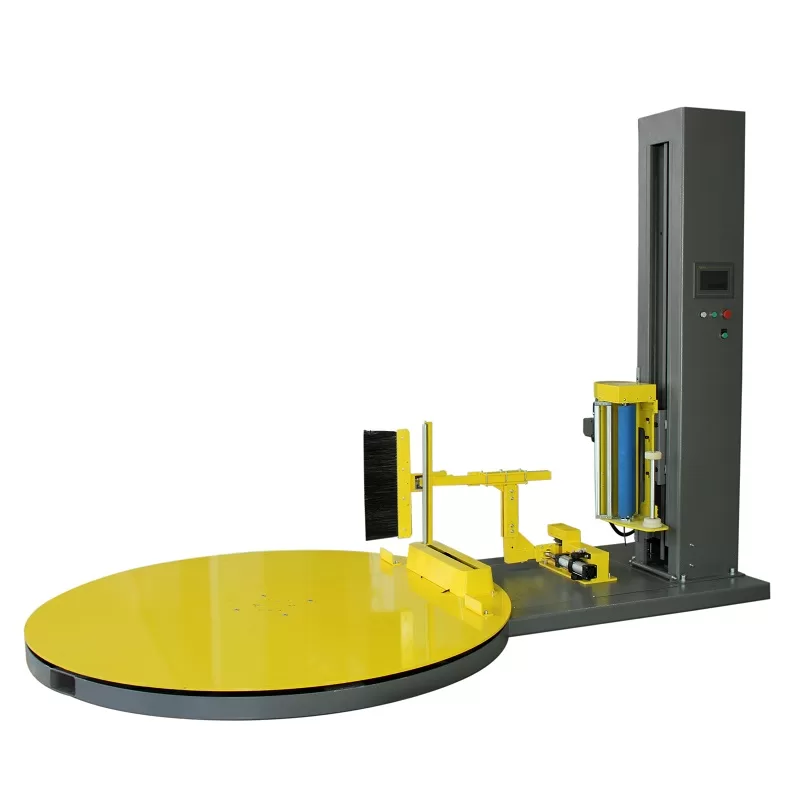

- Stretch Wrapping Cycle: The primary wrapping unit, often a rotating arm or turntable system, applies layers of stretch film around the sides of the pallet load, securing both the load and the edges of the top sheet.

- Film Cut and Seal: Upon cycle completion, the stretch film is automatically cut and sealed to the load.

- Pallet Exit: The fully wrapped and protected pallet is conveyed out of the station.

Key components typically include:

- Conveyor System: Transports pallets into and out of the machine.

- Wrapping Mechanism: Turntable or rotary arm applying stretch film.

- Top Sheet Dispenser: Holds, measures, cuts, and applies the top sheet film roll.

- Film Carriage: Controls the pre-stretch and application of the stretch wrap.

- Control System: PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) for managing operations, adjusting settings (wrap patterns, tension, sheet size), and diagnostics.

- Safety Features: Light curtains, safety fencing, emergency stops to protect personnel.

pallet stretch wrap 4 Key Benefits of Using a Top Sheet Dispenser

Integrating a top sheet dispenser offers several advantages beyond standard pallet wrapping:

- Enhanced Product Protection: Provides a barrier against dust, dirt, moisture, and potential contamination during storage and transit.

- Improved Load Stability: Helps to further secure the top layers of the load, especially for uneven or unstable products.

- Weather Resistance: Offers temporary protection against rain or snow if pallets are briefly stored outdoors.

- Increased Automation: Eliminates the manual, often inconsistent, step of applying top sheets by hand.

- Material Savings: Automated dispensing ensures optimal sheet size, reducing waste compared to manual application.

Typical Machine Specifications

Note: The following parameters represent typical specifications for this type of equipment. Actual machine capabilities can vary significantly based on the manufacturer and model. Always consult specific manufacturer documentation for precise details.

- Machine Type: Fully Automatic Stretch Wrapper with Integrated Top Sheet Dispenser

- Wrapping Material: LLDPE Stretch Film

- Top Sheet Material: Polyethylene Film

- Typical Maximum Pallet Load Height: 2000mm - 2800mm (Varies by model)

- Typical Maximum Load Weight: 1500kg - 2500kg (Varies by model)

- Machine Throughput: 25 - 60 pallets per hour (Dependent on wrap pattern and configuration)

- Top Sheet Coverage: Adjustable for various standard pallet dimensions

- Control System: PLC with touchscreen HMI

- Power Requirements: Typically 400V/480V, 3-Phase (Confirm with manufacturer)

- Safety Standards: Conforms to relevant safety regulations (e.g., CE, OSHA)

Common Industry Applications

The need for enhanced protection makes these machines valuable across various sectors:

- Food and Beverage: Protects packaged foods, ingredients, and beverages from dust, moisture, and contaminants, crucial for maintaining hygiene standards and product freshness. Essential for bagged goods, bottled items, and dairy products.

- Agriculture: Shields fertilizers, seeds, and animal feed from environmental exposure that could degrade quality. Protects harvested produce during transit.

- Pharmaceuticals and Healthcare: Ensures sterility and cleanliness by protecting medical supplies, devices, and pharmaceutical products from contaminants during warehousing and shipping.

- Building Materials: Guards bagged cement, plaster, insulation, tiles, and other construction materials against moisture damage which can render them unusable.

- Chemicals: Provides an extra layer of containment and protection for bagged or containerized chemicals, safeguarding against spills and contamination.

- Consumer Goods: Protects electronics, paper products, and other packaged goods sensitive to dust and moisture.

pallet stretch wrap 1 Considerations for Selecting a System

When evaluating an automatic pallet wrapper with a top sheet dispenser, consider:

- Load Characteristics: Dimensions (L x W x H), weight, stability, and specific protection needs.

- Throughput Requirements: Required pallets per hour to match production line speed.

- Operating Environment: Temperature (ambient, cold storage), humidity, and available space.

- Film Requirements: Type and gauge of stretch film and top sheet film needed.

- Integration: Compatibility with existing upstream and downstream conveyor systems and automation.

- Budget: Initial investment cost versus long-term savings in labor, material, and product damage reduction.

By integrating top sheet application directly into the automated wrapping process, manufacturers and distributors can significantly enhance load protection, improve packaging efficiency, and ensure products arrive at their destination in optimal condition. For further information on packaging standards, consult resources from organizations like the Packaging Machinery Manufacturers Institute (PMMI) or relevant ASTM International standards for stretch wrap films.