Enhancing Coil Handling Efficiency with Automated Wrapping and Conveyor Systems

In modern metal fabrication and processing environments, efficiently handling and packaging coils—be it steel, wire, or other materials—is crucial for maintaining workflow, protecting product integrity, and ensuring operator safety. An automatic coil wrapper integrated with a conveyor system represents a key component in streamlining these post-production processes. This integrated solution automates the application of protective stretch film, preparing coils securely for storage or shipment.

This article explores the function and benefits of utilizing online automatic coil wrapping systems within a manufacturing or fabrication setting.

Understanding Automatic Coil Wrapping Technology

An automatic coil wrapper is specifically engineered to apply stretch wrap or other packaging materials around the circumference and through the eye of a coil. This process typically involves an orbital wrapping mechanism where the film dispenser revolves around the stationary or rotating coil. Key operational aspects include:

- Consistent Application: Automated systems ensure uniform film tension and overlap, providing consistent protection and load stability.

- Material Versatility: These machines can often handle various packaging materials, including stretch film, VCI paper, or woven fabrics, depending on the specific protection requirements.

- Reduced Manual Intervention: Automation minimizes the need for operators to manually handle heavy coils or apply wrapping materials, reducing ergonomic risks and potential inconsistencies.

The Role of Integrated Conveyors in Coil Packaging Lines

Integrating an automatic coil wrapper with a conveyor system transforms it from a standalone unit into part of a seamless coil packaging line. Conveyors facilitate the automated movement of coils to and from the wrapping station.

- Streamlined Workflow: Coils move automatically from the production or slitting line exit, through the wrapping process, and onwards to staging, banding, or shipping areas.

- Increased Throughput: Continuous flow enabled by conveyors significantly reduces cycle times compared to manual loading and unloading or forklift-dependent operations.

- Improved Safety: Minimizing manual handling and forklift traffic around the packaging area enhances overall plant safety.

- System Integration: Conveyors can be synchronized with upstream and downstream equipment (e.g., weigh stations, strapping machines, palletizers) for a fully automated end-of-line solution.

Key Benefits of Online Automatic Coil Wrapping Systems

Implementing an online automatic coil wrapper with an integrated conveyor offers several operational advantages for fabricators and manufacturers:

- Enhanced Productivity: Automating the wrapping and transfer process significantly boosts packaging throughput compared to manual or semi-automatic methods.

- Improved Product Protection: Consistent, tight wrapping safeguards coils against environmental factors like moisture and dust, and prevents damage during handling and transit.

- Optimized Material Usage: Precise control over film stretch and application parameters reduces material waste.

- Labor Optimization: Frees up personnel from manual wrapping tasks to focus on higher-value activities.

- Increased Operational Safety: Reduces the risks associated with manually handling heavy coils and operating wrapping equipment.

coil packing Considerations for Implementation

When considering an automatic coil wrapper with a conveyor, several factors should be evaluated:

- Coil Specifications: Machine capacity must match the range of coil diameters, widths, and weights being processed.

- Throughput Requirements: The system's speed must align with production output.

- Packaging Material: Ensure compatibility with the required stretch film or other protective materials.

- Level of Automation: Determine the required degree of integration with existing production lines and downstream processes.

- Footprint and Layout: Allocate sufficient space for the wrapper, conveyors, and associated safety zones.

Exploring Coil Wrapping Machinery Options

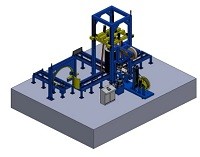

Different models cater to varying needs, from semi-automatic units to fully integrated lines. Below are examples illustrating different configurations:

|  |  |

| Wire coil packing machinery economic solution--FPW-300 | Semiauto Wire packing machinery--FPW-400 | Wire coil packing machinery--FPW-500 |

| .jpg) |  |

| Two material packing solution for Wire coil packing machinery--FPW-600 | Wire coil packing machinery with trolley--FPW-800 | Wire coil compactor&strapping machine |

Conclusion

Investing in an automatic coil wrapper with an integrated conveyor system is a practical step towards optimizing the coil handling and packaging process in demanding manufacturing environments. These automated solutions contribute significantly to operational efficiency by increasing throughput, ensuring consistent package quality, enhancing product protection, and improving workplace safety. By carefully evaluating specific operational needs and selecting the appropriate system configuration, fabricators can achieve substantial improvements in their end-of-line packaging operations.