Automatic Coil Stacking Machine for Standardized and Consistent Packaging

In the fast-paced world of manufacturing and logistics, efficiency and consistency are key to success. An automatic coil stacking machine is an essential tool for industries that handle coils, such as metalworking, textiles, and cable manufacturing. This article delves into the significance of automatic coil stacking machines, their benefits, and how they contribute to standardized and consistent packaging. We will explore various aspects, including functionality, types, advantages, and key considerations for choosing the right machine for your business needs.

Understanding the Basics of Coil Stacking

What is Coil Stacking?

Coil stacking refers to the process of arranging coils in a structured manner for storage or transportation. This is crucial in industries where materials are delivered in coil form, such as steel, aluminum, and wire products. Proper stacking not only ensures space efficiency but also protects the coils from damage.

Importance of Standardized Packaging

Standardized packaging is vital for several reasons:

- Efficiency: Consistent packaging reduces handling time and streamlines the logistics process.

- Protection: Properly stacked coils are less likely to sustain damage during transport and storage.

- Cost-Effectiveness: Efficient use of space can lower shipping costs and improve inventory management.

- Safety: Standardized packaging minimizes the risk of accidents in the warehouse or during transportation.

The Role of Automatic Coil Stacking Machines

What is an Automatic Coil Stacking Machine?

An automatic coil stacking machine is designed to automate the process of stacking coils in a standardized manner. These machines utilize advanced technology to enhance efficiency, reduce labor costs, and improve safety.

How Does It Work?

The operation of an automatic coil stacking machine typically involves:

- Feeding Mechanism: Coils are fed into the machine using conveyor belts or rollers.

- Stacking Mechanism: The machine uses robotic arms or automated systems to stack the coils in designated positions.

- Safety Features: Many machines are equipped with sensors to detect obstacles and prevent accidents.

- Control Systems: Advanced software allows for customization of stacking patterns and configurations.

Benefits of Using Automatic Coil Stacking Machines

1. Enhanced Efficiency

Automatic coil stacking machines significantly reduce the time required for stacking coils. By automating the process, businesses can handle a larger volume of coils in a shorter time frame, enhancing overall operational efficiency.

2. Consistency in Packaging

One of the standout features of automatic machines is their ability to deliver consistent packaging standards. Each coil is stacked in the same manner, which minimizes variations and ensures that all products are prepared for shipment uniformly.

3. Reduced Labor Costs

By automating the stacking process, companies can reduce their reliance on manual labor. This not only cuts down on labor costs but also allows staff to focus on other critical tasks within the production line.

4. Improved Safety

Automated machines are designed with safety in mind. They reduce the risk of injuries associated with manual handling, such as strains and accidents during stacking. Many machines come equipped with safety sensors to prevent collisions and ensure operator safety.

5. Better Space Utilization

Automatic coil stacking machines optimize space usage within warehouses. By stacking coils efficiently, they enable better organization and can lead to reduced storage costs.

6. Customization Options

Many automatic coil stacking machines offer customizable stacking patterns. This flexibility allows businesses to adapt to various coil sizes and shapes, making them versatile for different applications.

Types of Automatic Coil Stacking Machines

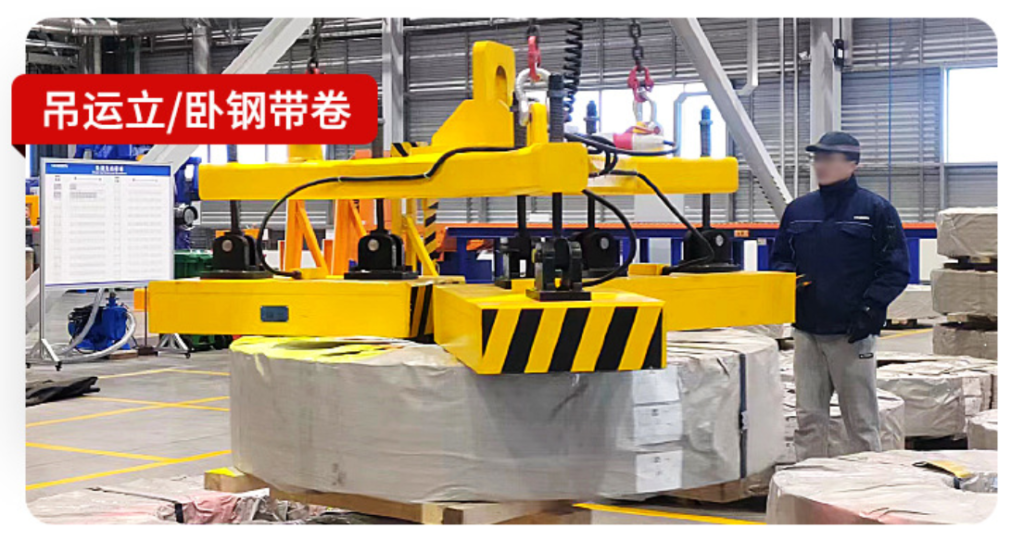

1. Horizontal Coil Stacking Machines

Horizontal coil stacking machines are designed to stack coils in a horizontal configuration. They are commonly used in industries where coils need to be stored flat.

2. Vertical Coil Stacking Machines

Vertical coil stacking machines stack coils vertically, which can be advantageous in terms of space savings. This configuration is often preferred in environments where height can be utilized for storage.

3. Robotic Coil Stacking Systems

Robotic systems employ robotic arms to handle the stacking process. These machines provide high levels of precision and can be programmed for various stacking configurations.

4. Modular Stacking Solutions

Modular stacking machines are designed to be flexible and can be reconfigured based on changing production needs. This adaptability makes them suitable for businesses that experience fluctuations in production volume.

Key Considerations When Choosing an Automatic Coil Stacking Machine

1. Production Volume

Assessing your production volume is crucial. Higher volumes may necessitate more advanced machines with greater throughput capabilities.

2. Coil Specifications

Consider the size, weight, and material of the coils you will be handling. Ensure that the chosen machine can accommodate your specific coil dimensions and weights.

3. Space Availability

Evaluate the available space in your facility for the stacking machine. This will influence the type and configuration of the machine you choose.

4. Budget Constraints

Determine your budget for the machine, keeping in mind not just the initial purchase cost but also long-term operational and maintenance expenses.

5. Maintenance and Support

Look for machines that offer comprehensive maintenance plans and strong customer support. Reliable service is essential for minimizing downtime.

6. Integration with Existing Systems

Ensure that the new machine can seamlessly integrate into your existing production line and software systems. Compatibility is key to maximizing efficiency.

7. Safety Features

Prioritize machines equipped with robust safety features. This includes emergency stop buttons, safety guards, and sensors to prevent accidents.

Real-World Applications

Case Study: Metal Manufacturing

A metal manufacturing facility implemented an automatic coil stacking machine to handle steel coils. The result was a 30% increase in efficiency and a significant reduction in labor costs. The consistent stacking patterns also improved the safety of storage areas.

Case Study: Cable Production

In a cable production plant, an automatic coil stacking machine was integrated into the production line. The ability to customize stacking patterns allowed the facility to adapt to various cable sizes, leading to better space utilization and a smoother workflow.

The Future of Automatic Coil Stacking Machines

As technology continues to advance, the future of automatic coil stacking machines looks promising. Innovations such as AI-driven automation, IoT integration, and enhanced robotics are likely to play a significant role in improving efficiency and flexibility.

1. AI and Machine Learning

The incorporation of AI can optimize stacking processes by analyzing production data and predicting the most efficient stacking patterns in real-time.

2. IoT Connectivity

IoT-enabled machines can provide valuable insights into operational performance. Real-time monitoring can help identify potential issues before they lead to downtime.

3. Enhanced Robotics

Future machines may incorporate more advanced robotics capable of handling a broader range of coil sizes and weights, further increasing versatility.

Conclusion

Investing in an automatic coil stacking machine is a strategic decision that can enhance your manufacturing and logistics operations. By providing standardized and consistent packaging, these machines improve efficiency, reduce labor costs, and enhance safety. When choosing the right machine, consider your specific production needs, coil specifications, and budget constraints. As technology continues to evolve, staying informed about advancements in automatic coil stacking machines will ensure that your operations remain competitive and efficient. By making the right choice, you can streamline your processes and position your business for future success.