What Makes an Automatic Aluminum Profile Film Tapping Machine Integration Critical for Modern Packaging?

I have seen many businesses struggle with inefficient manual tapping processes. They waste labor, risk product damage, and hurt output. A fully integrated system solves these problems easily.

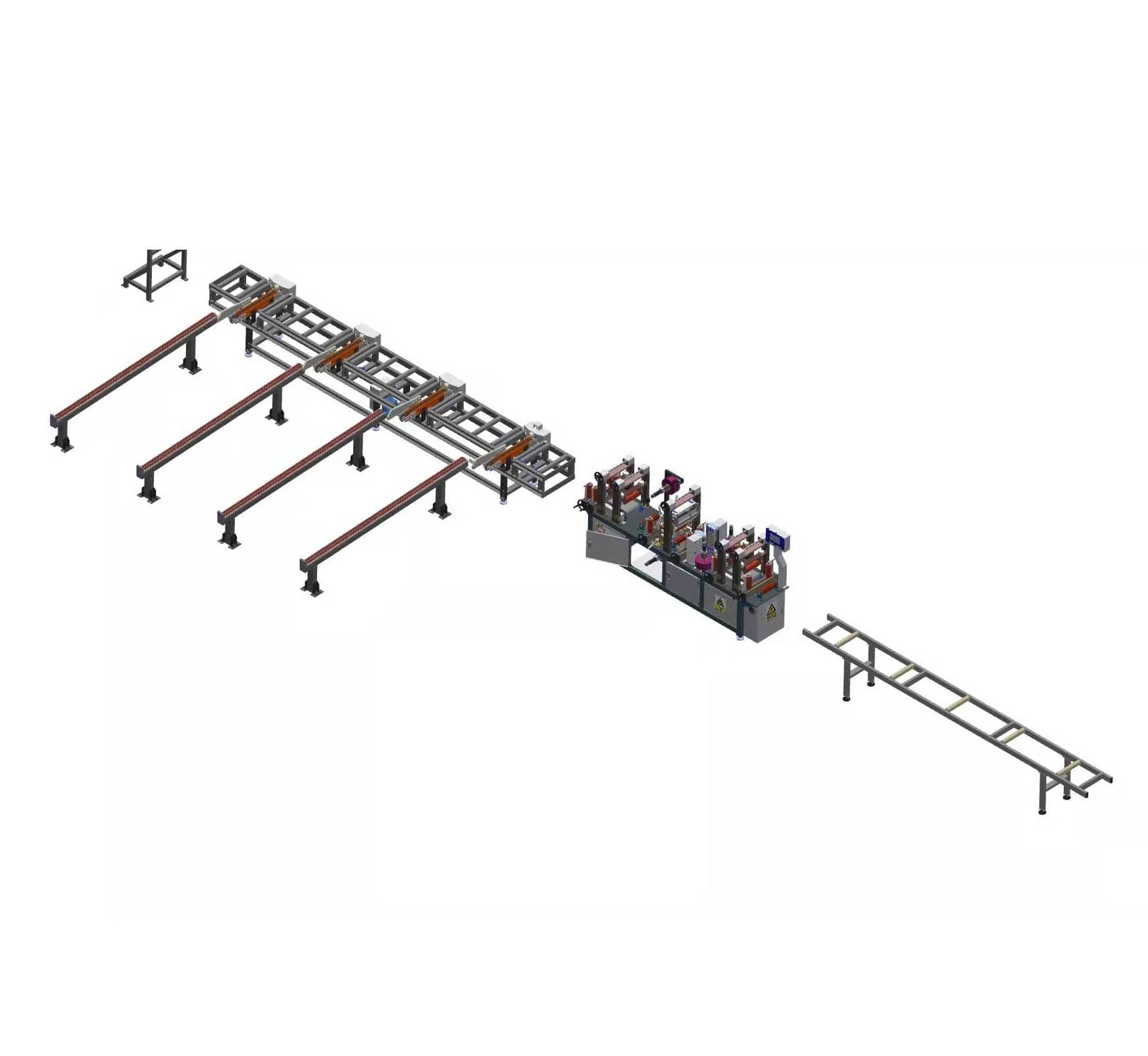

An automatic film tapping machine secures aluminum profiles with precise tension. It lowers wrapping errors, removes extra labor, and boosts protection. It regulates film usage and enables uniform coverage, which reduces shipping damage and builds customer trust.

I want to explain how this integrated approach changes modern packaging. This method helps manufacturers overcome daily challenges. It also opens new opportunities for scaling up production. My experience at FHOPEPACK shows that a well-planned system streamlines the entire operation. Let me share how this solution supports accuracy, cost effectiveness, and better workflow.

How Does a Film Tapping Machine Streamline Aluminum Profile Packaging?

I see many factories lose time on manual wrapping tasks that demand focus and physical effort. That leads to mistakes, damage, and uneven film tension.

This film tapping machine removes guesswork. It automates the wrap around aluminum profiles, ensures strong seals, and manages tension precisely. That lowers rework and shortens production runs.

I understand how significant these machines are. They save labor costs, bring uniform results, and protect products during transit. They also speed up the wrapping cycle. Workers can concentrate on quality checks instead of wrestling with film and tape.

Dive Deeper: Streamlined Workflow and Automation for Better Efficiency

I have dealt with inconsistent wrapping methods before. I recall trying to manage a busy shift where operators had to tape each aluminum profile by hand. It was time-consuming. It also introduced a lot of variation in tape tension and coverage. Some wraps were too loose, which exposed edges. Others were too tight, which wasted film and tore it. This combination of problems slowed production and raised the risk of defects.

The Importance of Consistent Application

A film tapping machine applies consistent tension every time. It moves film around the profile without leaving gaps or wrinkles. That improves surface protection and prevents corners from tearing the film. Automated tension controllers measure how tight the wrap should be. If a profile is narrower, the system adjusts. If a profile is thicker, it adjusts again. That uniform approach cuts down on film waste and lowers the risk of damage.

How a Standard Process Saves Time

When I compare manual and automated methods, I see a big difference in overall workflow. The machine can tap multiple profiles in a row without pause. It only needs a quick spool change when the film runs low. That means fewer stops in the production line. I remember times when we had to manually stop because an operator got too tired or made an error. With an automated system, that is mostly gone. Production stays predictable.

Reduced Labor Involvement

One advantage is that an operator can oversee several machines or focus on final inspections. The system handles the heavy and repetitive work. This means the staff can be used for more important tasks, like ensuring quality. It also helps reduce the strain of manual wrapping on workers. That can lower injury risk over time. I have found that a more ergonomic environment often leads to happier employees and more stable daily output.

Enhanced Precision and Protection

Aluminum profiles often have sensitive finishes. They can scratch easily if the wrapping is uneven. A film tapping machine lowers friction on these surfaces by using a controlled tension path. Operators set the tension level, and sensors maintain it. This means fewer scuff marks. Also, the system can add protective corners or padding if needed. That is common in systems with advanced integration. It ensures that the corners of each profile get extra cushioning.

Data-Driven Optimization

Modern film tapping machines may log production data. They record how many profiles were wrapped in a given period. They can also track film usage and detect if tension or temperature changes might affect wrapping quality. Managers can review this data to spot inefficiencies or to plan maintenance. This approach helps with scheduling. It lowers downtime. I remember a scenario where daily logs revealed that film usage spiked each afternoon. It turned out an operator was over-tightening the wrap. Adjusting settings solved that problem, saving both film and money.

| Benefit | Explanation | Impact on Operations |

|---|---|---|

| Consistent Tension | Automation controls wrap pressure accurately | Reduces waste, prevents edge damage |

| Faster Throughput | Continuous feeding and automated taping | Speeds production, less idle time |

| Labor Reallocation | Frees staff for tasks beyond manual wrapping | Improves efficiency and workforce morale |

| Improved Protection | Uniform coverage and optional padding | Lowers chance of transit damage |

| Data Monitoring | Tracks usage and detects irregularities | Enables targeted improvements and planning |

I think that if a plant deals with large volumes of aluminum profiles, an integrated tapping system is a major upgrade. The consistent wrap keeps the product safe. The automated approach cuts labor costs. Production becomes more predictable. Another point is that a single machine can handle various profile dimensions if set up with the right adjustments. That flexibility helps facilities that handle different product types.

A film tapping machine also integrates with other packaging machines, like shrink-wrapping systems or automated pallet wrappers. This synergy pushes the entire operation into a unified workflow. When each station communicates seamlessly, the line hits higher throughput. That adds to the bottom line. My experience at FHOPEPACK shows that once a line implements advanced automation, managers rarely want to go back to manual processes.

What Are the Key Advantages of Automated Integration?

I used to work on lines that had standalone machines for each step. That caused confusion and gaps in production. Automated integration is different.

It merges feeding, tapping, sealing, and unloading into one workflow. This harmony eliminates waiting times, prevents collisions, and improves overall throughput. It also collects data across stages for better oversight.

I think integration matters because it gives full control over each packaging phase. Operators track real-time production and spot small errors quickly. That leads to consistent, high-quality output. It also reduces labor strain. More tasks become automated, so fewer people are needed for repetitive duties.

Dive Deeper: Understanding the Power of a Connected System

In my career, I have seen partial integrations that leave out crucial steps. Sometimes, a system will automatically feed aluminum profiles into a tapping station, but the operator must manually unload or add protective corners. That partial solution still leads to slower throughput. A fully integrated approach synchronizes each process so the product glides from start to finish. This synergy cuts misalignment issues, which often cause tears or folds in the film.

Clarity Through Real-Time Data

Modern machines share performance metrics with a central interface. Operators see how many profiles each station processes, how much film remains, and if any sensor detects misalignment. This real-time visibility lets managers correct small issues before they stop the entire line. If a film roll is running low, the system can send an alert. The operator replaces it quickly, avoiding downtime. This sort of planning helps with large orders, where every minute counts.

Reduced Human Intervention

An integrated line needs minimal manual handling. The profiles move on conveyors, get tapped, and then move to the next station without an operator physically transferring them. This lessens the chance of dropping or bumping. It lowers potential for injuries. It also means more uniform results, because automation does not get tired or distracted. I have seen lines run consistently for hours, only pausing for scheduled maintenance or spool changes.

Higher Throughput and Scalability

Integration speeds up each stage by removing waiting times. If the tapping station completes a wrap but the next station is not ready, it can cause backups. A connected line coordinates flow rates. It ensures that each station runs at the same pace. This approach can double or triple production output when compared to nonintegrated setups. Scaling becomes simpler. If the demand grows, managers can add parallel lines or upgrade station capacity. They do not have to redesign the entire plant from scratch.

Lower Material Waste

An integrated approach can optimize film usage. Sensors confirm each wrap cycle so the system only uses the exact amount of film needed. Some advanced machines can measure the length of each profile, adjusting film usage accordingly. That stops under-wrapping or over-wrapping. It also saves money on materials, which is significant over time. I remember a project that switched to a fully automated line and cut film waste by 15%. That was a major budget improvement.

Better Quality Control

Tapping, sealing, corner protection, and other packaging steps can all feed data into a single dashboard. This helps quality inspectors confirm that the final package meets specifications. The integration ensures each step logs the correct parameters. If a profile is out of tolerance, the system can reject it automatically. I recall a case where slight dimension errors caused repeated film tears. After integrating a dimension-check sensor, the system flagged misaligned profiles. It prevented downtime and kept the line running smoothly.

| Integration Benefit | Description | Resulting Improvement |

|---|---|---|

| Unified Workflow | Automatic flow across feeding, tapping, etc. | Less waiting, higher output speed |

| Real-Time Monitoring | Data sharing among all stations | Quick detection of issues, reduced delays |

| Consistent Quality | Automated checks and precise tension control | Fewer defects, stable wrap performance |

| Lower Operating Costs | Less labor, minimized film waste | Bigger profits, faster ROI |

| Simple Scalability | Stations can be expanded or upgraded | Easier to handle sudden demand increases |

I believe the biggest plus is how integration simplifies employee roles. Staff no longer babysit each station. They supervise the entire line and step in only when there is a real problem or maintenance requirement. That fosters a smoother environment. It also opens up time for staff training or continuous improvement projects. I have seen how a more automated line can free managers to focus on planning new product lines or negotiating better deals with suppliers.

Another point is synergy with other automated lines. Some plants combine tapping systems with labeling, barcoding, or product inspection. If you can maintain a unified data system, all these steps feed the same software. That means a product can be tapped, labeled, and scanned into inventory without repeated manual entries. This approach reduces errors and keeps track of each profile’s journey, from wrapping to shipping. Over time, that can simplify audits and fulfill customer traceability requests.

When you weigh the benefits of integrated automation, it is clear how it transforms the packaging landscape. By linking each station, managers gain better control, real-time insight, and consistent quality. Costs drop because labor overhead and waste go down. Output climbs because each step moves in sync. That is why I think automated integration is more than a convenience. It is a necessity for companies competing in today’s fast-paced market.

How Do You Select the Right Tapping Machine for Your Production Needs?

I learned that a perfect match depends on profile size, desired throughput, and budget constraints. I always begin by assessing total output and the range of product dimensions.

I also check if the client wants partial or full integration. Some lines only need tapping. Others demand extra stations like corner protectors, labeling, or strapping. A tailored approach saves money and avoids overengineering.

I tell buyers to consider the service and support available. They should check if the manufacturer offers training, spare parts, or remote diagnostics. I have seen many issues solved quickly when operators know basic troubleshooting steps. That can keep the line running smoothly.

Dive Deeper: Steps to a Well-Informed Tapping Machine Decision

Choosing a tapping machine is not just about speed. It is about matching technology, space, and future expansion. I used to handle projects where a client bought the biggest, fastest machine they could find, only to discover it needed more floor space than they had. Or they realized the machine was too complex for their staff to maintain. These mistakes can be avoided by following a systematic approach.

1. Define Production Goals

Start by asking how many profiles you need to wrap daily, weekly, or monthly. Then consider seasonality. Some factories have consistent demand, while others see seasonal spikes. If you experience large fluctuations, you may need a machine that can handle peak demand or allow partial capacity during quieter periods.

2. Evaluate Profile Dimensions

Check the length, width, and shape of your aluminum profiles. Some machines work great for small or medium profiles but struggle with extra-long pieces. Others might handle unusual shapes. Measure all variations to see if a single machine can handle them. If not, you might need a custom setup or multiple stations.

3. Assess Available Space

These tapping machines can take up more floor area than you might guess. Measure doorways, aisles, and possible paths for feeding. Also consider how many conveyors or side equipment you might add later. A cramped layout can cause collisions or difficulty in moving raw materials. If space is tight, a compact design or a machine with a smaller footprint might be necessary.

4. Determine Automation Level

Not every facility needs fully automated loading, tapping, and unloading. A semi-automatic setup might suffice for smaller operations. If you plan to grow or you already run high volumes, an automated line often yields better returns. Automation also helps if you struggle with high labor turnover or want consistent outcomes. I have seen that a fully automated line can pay for itself through savings on labor and less product damage.

5. Consider Maintenance and Support

A high-tech machine is only as good as the support behind it. Make sure you have easy access to spare parts, either from the manufacturer or local distributors. Check if they offer remote diagnostics or telephone support. I once visited a plant that experienced repeated sensor failures because of the dusty environment. They did not have the correct spares on hand. Each downtime event cost them hours of production. Good planning for maintenance can prevent such setbacks.

6. Budget and Return on Investment

I often advise clients to see the bigger picture. A more expensive machine might wrap profiles faster and reduce labor costs. If the difference in cost is offset by monthly savings, the payback period can be shorter than expected. On the other hand, if you rarely need high output, a simpler machine might be enough. Always weigh the machine’s capacity and features against your real throughput demands.

7. Future Expansion

If you expect to grow your product line or move into new markets, choose a tapping machine that can scale. Maybe you want to add labeling or corner protection in the future. Or you might incorporate robotics for palletizing. A modular system that can integrate with these expansions makes sense. If you buy a machine with no room for upgrades, you might need a full replacement in a few years.

| Selection Factor | Why It Matters | Ideal Approach |

|---|---|---|

| Production Volume | Determines required speed and machine size | Calculate peak and average demands |

| Profile Dimensions | Dictate machine compatibility and capacity | Measure all variations and shapes |

| Floor Space | Ensures the machine fits with room for feeding | Draft a layout to avoid collisions |

| Automation Needed | Balances budget and labor availability | Choose semi- or fully-automated line |

| Maintenance Support | Avoids long downtime or frequent breakdowns | Verify spare parts and training availability |

| Budget Constraints | Shapes the technology level you can afford | Estimate ROI based on labor and film savings |

| Growth Plans | Anticipates expansions or new product lines | Opt for modular, upgradable designs |

I also believe in testing equipment whenever possible. Visiting a demonstration line can offer insights that brochures cannot match. Observing how quickly a machine completes a wrap, how often operators intervene, or how the machine handles unusual profiles is valuable. Some suppliers may let you send sample profiles so they can do a test run and share the results. That can confirm if the tapping machine meets your requirements.

In my own experience, a thorough approach that weighs all these factors saves a lot of headaches. When you match the correct machine to your operation, you get consistent tapping, fewer mistakes, and a more productive team. That stable environment makes it easier to plan daily tasks. It also enhances your facility’s reputation for delivering high-quality aluminum profiles. Good packaging protects surfaces and ensures each shipment arrives in perfect condition.

By following these steps, you can choose a tapping machine that meets current production requirements and leaves room for future improvements. I have seen many businesses flourish by adopting a machine that fits their workflow, staff capabilities, and customer demands. The machine becomes a reliable asset rather than a complicated burden. That is where the real value lies.

Conclusion

I learned that an automatic aluminum profile film tapping machine simplifies production and protects delicate surfaces. It ensures stable tension, reduces labor strain, and unifies each packaging stage when integrated properly. I have seen how a smooth line cuts down on errors and prevents wasted materials. In my experience at FHOPEPACK, the best setups match machine capacity, space, and future goals. They also rely on robust support for maintenance and staff training. That creates a strong return on investment. I trust this guide helps clarify why an automatic film tapping solution is essential for modern packaging. It saves money. It elevates product quality. It helps a business scale. This is how advanced engineering transforms daily wrapping tasks into a fluid, reliable process.