Original email communication for aluminum profile packaging line

http://www.fhopepack.com/Aluminum_profile_packing_line.html

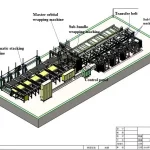

An aluminum profile packaging line is a manufacturing system designed to package aluminum profiles for shipping or storage. The packaging line typically consists of several components that work together to achieve an efficient and effective packaging process.

Here are some of the key components that may be included in an aluminum profile packaging line:

Automatic cutting machine(optional): An automatic cutting machine is used to cut aluminum profiles to the desired length. The machine is designed to ensure accuracy and consistency in the cutting process.

Conveyor system: A conveyor system is used to transport the aluminum profiles from one component of the packaging line to another. The conveyor system can be customized to accommodate different shapes and sizes of profiles.

Wrapping machine: A wrapping machine is used to wrap the aluminum profiles in a protective material, such as plastic or foam. The wrapping machine can be designed to handle different types of wrapping materials and to adjust to different sizes and shapes of profiles.

Labeling machine: A labeling machine is used to apply labels to the wrapped aluminum profiles. The labeling machine can be customized to include different types of information, such as product codes, serial numbers, and shipping addresses.

Inspection system(optional): An inspection system is used to check the quality of the aluminum profiles and the packaging materials. The system can detect any defects or flaws in the profiles or packaging materials, and can automatically reject any products that do not meet the required standards.

Palletizing machine(optional): A palletizing machine is used to stack the wrapped and labeled aluminum profiles onto pallets for shipping or storage. The palletizing machine can be customized to handle different sizes and weights of profiles, and to stack the profiles in different configurations to maximize space utilization.

Overall, an aluminum profile packaging line can help to streamline the packaging process, improve efficiency, and ensure the quality of the final product. By automating many of the steps involved in packaging, the line can also help to reduce labor costs and minimize the risk of human error.