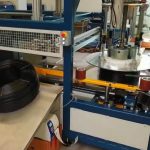

It is an anutomatic hose and tube winding and binding machine for different pvc pipe, pu pipe, gas pipe…

https://www.fhopepack.com/Automatic-Coiling-Machine/index.html

An air tube winding and binding machine is a type of machine that is used to automatically wind and bind air tubes for efficient transportation or storage. The machine is typically designed to work with air tubes of varying sizes and can be customized to accommodate specific packaging requirements.

The winding and binding process is typically initiated by feeding the air tubes onto the in-feed conveyor of the machine. The machine then automatically winds the air tubes onto a spool or reel and binds them together for efficient transportation or storage.

Some common features of air tube winding and binding machines include:

- Adjustable tube size: Many machines allow you to adjust the tube size to suit the specific requirements of your packaging needs.

- Automatic winding and binding: This feature allows the machine to automatically wind the air tubes onto a spool or reel and bind them together for efficient transportation or storage.

- In-feed conveyor: The in-feed conveyor automatically feeds the air tubes onto the machine, allowing for a continuous and efficient production line.

- Variable speed controls: These features allow you to adjust the speed of the winding and binding process, which can help ensure a consistent and high-quality result.

- Sturdy construction: Air tube winding and binding machines are designed to be durable and long-lasting, with sturdy construction and high-quality components.

Overall, air tube winding and binding machines can help increase efficiency and productivity in manufacturing and production facilities by automating the winding and binding process and reducing the need for manual labor. They are available in a range of sizes and configurations to suit different air tube sizes and packaging requirements, and can be customized with additional features and options to meet specific needs.

Related posts:

automatic hose and pipe coiling and binding machine video

automatic hose and pipe coiling and binding machine video  Automatic plastic pipe winding and strapping machine

Automatic plastic pipe winding and strapping machine  automatic cable wire coiling and binding machine video

automatic cable wire coiling and binding machine video  wire wrapping machine and copper tube packing machine

wire wrapping machine and copper tube packing machine  Stainless steel tube bag packing machine

Stainless steel tube bag packing machine  automatic aluminum conveying and bundling machine

automatic aluminum conveying and bundling machine  Automatic aluminum sub-bundle wrapping & strapping machine

Automatic aluminum sub-bundle wrapping & strapping machine  Automatic pipe bagging machine&tube bundle strapping machine

Automatic pipe bagging machine&tube bundle strapping machine  Solution for tube bundling and bag packing

Solution for tube bundling and bag packing  automatic coil winding and strapping machine

automatic coil winding and strapping machine