Upender Machine Price

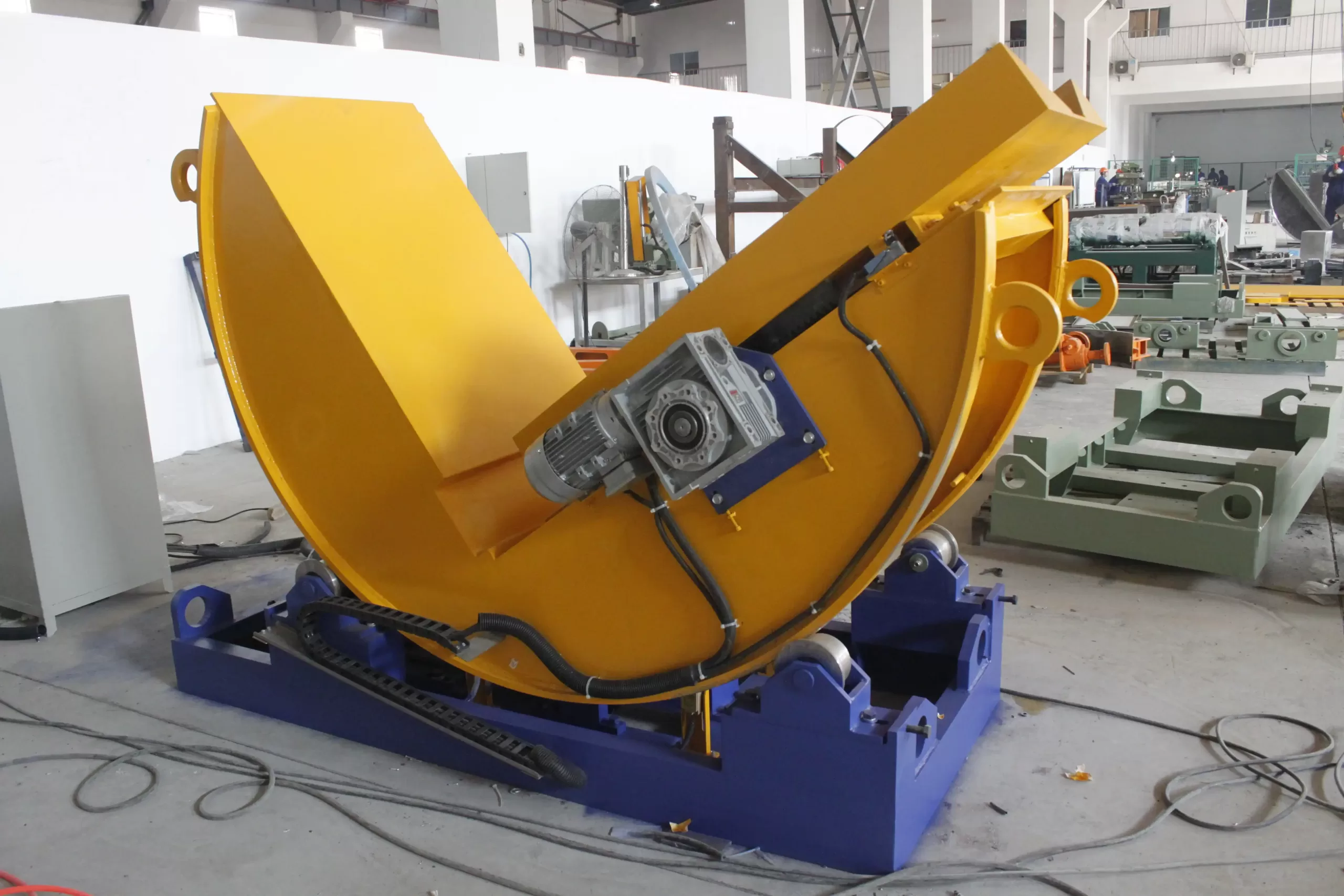

The cost of upender machines is one of the most critical factors for businesses considering operational upgrades. These machines are pivotal in industries dealing with heavy, bulky materials, enabling efficient material handling and reducing manual labor. Understanding the pricing structure of upender machines not only helps in budgeting but also ensures long-term operational benefits. [featured image]

In today’s competitive market, the price of an upender machine varies significantly based on its size, features, and technology. Companies must navigate this landscape carefully to secure equipment that meets their needs while staying within budget constraints. This article dives into the details of upender machine pricing and provides actionable insights for buyers.

A crucial aspect of pricing is not just the machine itself but the added value it delivers. While cheaper options might seem appealing initially, the cost-to-value ratio often leans in favor of more robust, customizable models. This balance between upfront investment and operational savings is a cornerstone of informed purchasing decisions.

[claim] Buyers must evaluate not only the upfront costs but also long-term expenses, including maintenance, downtime, and operational efficiency. Comprehensive research and strategic negotiation can lead to a cost-effective purchase without compromising quality.

1. What Factors Affect the Price of an Upender Machine?

1.1 Size and Capacity of the Machine

The size and capacity of an upender machine are the most obvious factors impacting its price. Smaller machines designed for lightweight operations are typically less expensive than industrial-grade models capable of handling several tons of material. However, it's not just about size; the machine's ability to handle specific dimensions, weights, or material types also comes into play.

Choosing the right size is crucial. An undersized machine may lead to inefficiencies and increased wear, while an oversized one could inflate costs unnecessarily. Businesses must evaluate their material handling needs carefully to find the perfect balance.

1.2 Technology and Automation Features

Modern upenders often come equipped with advanced technologies such as programmable logic controllers (PLCs), IoT-enabled monitoring, and safety systems. These features significantly enhance performance but also increase the upfront cost.

When evaluating technology-driven models, consider how automation aligns with your operational goals. Advanced features can reduce labor costs and boost efficiency, making them a worthwhile investment for high-volume operations.

1.3 Brand Reputation and Manufacturing Standards

Dive deeper into the impact of brand reputation on pricing. Established manufacturers with a proven track record often charge a premium for their machines. This cost reflects not just the machine's quality but also the assurance of reliable after-sales support and compliance with safety standards.

While newer or lesser-known brands might offer budget-friendly options, it's essential to investigate their reliability, warranty policies, and user reviews to avoid hidden costs down the line.

2. How Can You Determine the Right Upender for Your Budget?

2.1 Assessing Your Operational Needs

To determine the right upender machine for your budget, start by assessing your specific operational needs. Consider factors such as material type, weight range, and the frequency of operations. A thorough understanding of your requirements helps narrow down choices and avoid overspending on unnecessary features.

The key is to differentiate between "nice-to-have" and "must-have" features. Prioritize the latter to stay within budget while ensuring the machine performs optimally for your application.

2.2 Comparing Price and Value

The price of an upender machine should always be evaluated alongside the value it brings. Factors like energy efficiency, ease of maintenance, and warranty terms play a significant role in determining value. Machines with higher upfront costs often prove economical over time due to reduced maintenance and operational savings.

Investing in a machine with lower operational costs may require a higher initial outlay, but it can substantially benefit the company over the machine's lifecycle.

2.3 Understanding Financing and Leasing Options

Dive deeper into the financial flexibility available to buyers. Many manufacturers offer leasing options or financing plans to make high-quality upenders more accessible. These options can spread out the cost, enabling businesses to acquire premium equipment without straining their capital.

Evaluate the terms of financing carefully, considering interest rates, payment schedules, and any hidden charges. Proper financial planning ensures you maximize your investment while maintaining cash flow.

3. Is Customization Worth the Additional Cost?

3.1 Tailoring Machines to Your Needs

Customization offers a significant advantage, allowing businesses to adapt upender machines to their specific operational requirements. Whether it's modifying the machine to handle unique materials or integrating it with existing systems, customization can streamline workflows and enhance productivity.

However, customization often comes at a premium. Businesses need to assess whether the additional cost aligns with their operational goals and long-term benefits. Tailored solutions are most valuable for industries with niche needs or specialized processes.

3.2 Balancing Custom Features with Budget Constraints

Custom features should be selected strategically to avoid overcapitalization. While features like automated controls or enhanced safety systems add value, excessive customization may inflate costs unnecessarily.

Evaluate customization options by determining their return on investment (ROI). Features that directly impact efficiency, safety, or longevity should take priority, while less critical ones can be set aside for future upgrades.

3.3 Dive Deeper: The ROI of Customization

Customization is not just an expense; it's an investment in operational efficiency. For instance, an upender designed to integrate seamlessly with an automated production line reduces downtime and boosts overall throughput. Similarly, safety enhancements can prevent costly workplace incidents, making customization a cost-effective choice over time.

While upfront costs might be higher, businesses often recoup these expenses through reduced labor costs, enhanced productivity, and fewer operational disruptions.

4. What Are the Long-Term Financial Benefits of Investing in an Upender?

4.1 Reduced Labor and Maintenance Costs

Investing in an upender machine can significantly reduce labor requirements by automating material handling tasks. This not only lowers payroll expenses but also minimizes the risk of workplace injuries, leading to long-term savings.

Maintenance costs are another crucial consideration. High-quality upenders from reputable manufacturers often come with durable components and extended warranties, reducing the likelihood of frequent repairs. Over time, these factors contribute to a lower total cost of ownership.

4.2 Increased Operational Efficiency

Efficiency is a direct contributor to cost savings. Upender machines that operate with precision and speed enhance overall productivity, allowing businesses to meet production targets without additional resources.

Modern machines equipped with energy-efficient technology also reduce utility costs. These savings, while incremental, add up significantly over the machine's lifecycle.

4.3 Dive Deeper: Enhanced Scalability and Flexibility

Beyond immediate financial benefits, upender machines provide long-term value by supporting business growth. Their scalability allows companies to adapt to increasing production demands without requiring new equipment. Additionally, versatile models can handle a wide range of materials, ensuring relevance even as operational needs evolve.

Strategic investment in an upender not only addresses current challenges but also positions businesses for future success. This forward-thinking approach makes high-quality machines a cornerstone of sustainable growth.

Conclusion

Investing in an upender machine is more than just a purchase; it’s a strategic decision that impacts operational efficiency, safety, and profitability. While upfront costs can seem daunting, the long-term benefits—ranging from reduced labor and maintenance expenses to enhanced scalability—make these machines indispensable for modern industries.

[claim] Businesses must prioritize machines that offer the right balance of cost, features, and reliability. By focusing on long-term value and aligning purchases with operational goals, companies can ensure a return on investment that justifies every dollar spent.