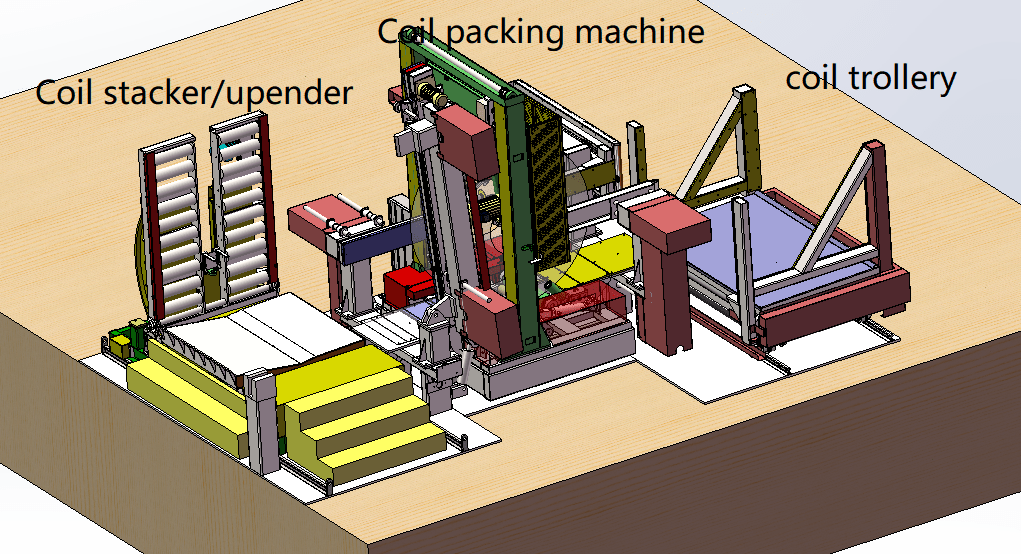

Slitting coil packing line for sale

Basic requirements for vertical steel coil packaging line.

✧ PLC control, HMI touch screen operation.

✧ Frequency inverter for speed adjustment that is for packaging overlap adjustment for the paper packaging material per ring speed and roller speed.

✧ Main board adjusted up and down automatic per OD with sensor height checking.

✧ The protective rollers up and down on the wrapping station adjustable for steel coils in different widths.

✧ Manipulator swing arm to automatically insert the packaging material to the packing position

✧ packaging material next to the wrapping staiton with storage box that can be automatic pre-feeding and cutting per coil size.

✧ Automatic hydraulic ejection mechanism to push out the steel coil after packaging from wrapping station to the passway tunnel to the upender.

✧ The packaging tension is adjustable by presetting on the tensioner before wrapping.

✧ Carrier rollers and protective rollers are covered with high pressure-resistant polyurethane.

In& Out passway

Before and after vertical coil packaging machine there are passways tunnel which is for supporting the coil rolling in and out. In the out feeding passway tunnel, there is a buffering device for receiving steel coil for decrease the coil rolling force that is allow the coil gently rolling to the upender. It is important part for the heavy coil movment.

✧ Widht of the tunnel adjustable per different coil width.

✧ High-quality steel structure, sturdy, thick and durable machine body.

✧ Coil rolling in and out.

Upender Stacking machine

Ø Function:

The upnder is for receiving the steel coil one by one from the wrapping machine. By turning 90 degree, It stacking the coils frome vertical into horizontal on the pallet.

Ø Basic features

✧ The upender with conveyor table and trolley for position adjustment .

✧ With powerful motor and gear driven, safe and stable.

✧ One side of the working table is V-shaped, and the other side is with roller conveyor.

✧ Automatic pallet centering mechanism for pallet positioning up and down adjustment so that the coil can be place on the center of the pallet.

✧ The base adopts four-roller mechanism to ensure the smooth operation.

✧ Carrier roller and turning base are covered with safety protection material to ensure the coil safety.

Slitting coil packing line for sale

✧ There is over-load protection device. If the loading exceeds, the upender will automatically shut down and lock without damaging the motor.

✧ Electrical parts with overload circuit breakers, and overcurrent protection contactors follows to the EU standard.

✧ The motor has brake for self-locking , which makes the upender can be stopped and locked at any position.

&nbs

.jpg)