Pallet Exchanger Solutions

When it comes to the efficient handling of heavy materials, the role of pallet exchangers cannot be overstated. These industrial solutions, designed to swap pallets quickly and safely, are essential in optimizing supply chain processes. I’ve seen firsthand how incorporating a pallet exchanger into operations can transform the logistics of a facility, enhancing productivity and reducing downtime. Whether you're in manufacturing, warehousing, or distribution, the efficiency gained by switching to these automated solutions speaks volumes.

A pallet exchanger offers more than just convenience. It can be a game-changer for facilities looking to reduce labor costs and improve throughput. In this article, I’ll dive into why choosing the right pallet exchanger solution is crucial, and how the latest technologies are making these systems more reliable and efficient. From ensuring faster operations to minimizing handling errors, the benefits are clear. But, as with any investment, understanding how to select the best system for your unique needs is key.

The growing demand for faster turnaround times and better resource management has made the need for high-performance pallet exchangers even more pressing. With that, let’s explore the key factors to consider when evaluating pallet exchanger solutions and how they can be integrated into your existing operations for optimal results.

1. How Do Pallet Exchangers Work in the Modern Warehouse?

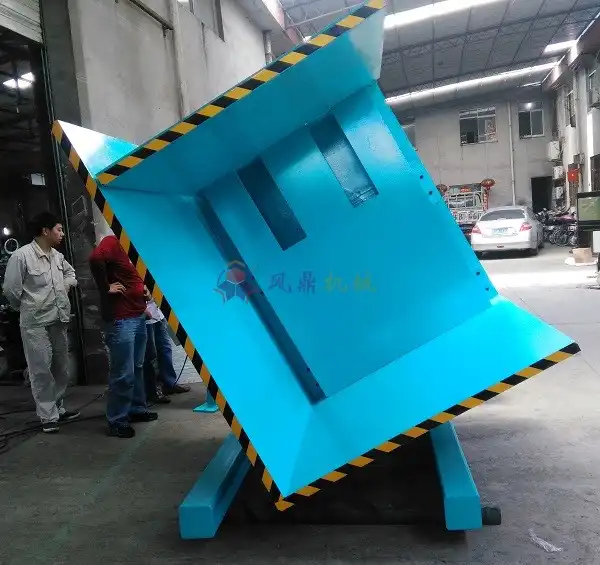

Pallet exchangers are often seen as a bridge between manual labor and full automation in the warehouse. These systems work by automatically switching the loaded pallets onto new ones without the need for manual handling, saving both time and effort. The process is simple: once a pallet is loaded with goods, the exchanger mechanism lifts the pallet, separates it from the load, and replaces it with a fresh pallet. The system's design reduces the need for forklifts and minimizes the physical strain on workers, leading to fewer accidents and more streamlined operations.

This process may seem straightforward, but the technology behind it is constantly evolving. Modern pallet exchangers are equipped with sensors and intelligent controls to detect the load, ensuring that only properly positioned pallets are swapped. The precision required for these tasks means that the machine can operate at faster speeds while maintaining high levels of accuracy. This is critical when dealing with high-volume environments where every second counts.

The automation of pallet exchange processes also allows for better workflow planning. By reducing human error and ensuring that pallets are changed at the correct intervals, you can ensure smoother, uninterrupted production cycles.

2. What Are the Key Benefits of Automated Pallet Exchangers?

Automated pallet exchangers offer a range of benefits that significantly impact efficiency and cost-effectiveness. One of the primary advantages is the reduction in manual labor. With a system that operates autonomously, workers are freed up to focus on other tasks that require human oversight or more complex decision-making. In turn, this boosts productivity and allows companies to allocate resources more effectively.

Another major benefit is the reduction in workplace injuries. Manual pallet handling often leads to back, shoulder, and other musculoskeletal injuries due to the repetitive nature of the task. By automating this process, workers are less likely to suffer from these common workplace ailments, leading to a healthier workforce and fewer lost days due to injury.

In addition, these systems can lead to significant space savings in warehouse operations. Since the machines operate with precision, they allow for a more compact storage layout, which means more goods can be stored in the same physical space. This results in better utilization of available warehouse real estate, which is often one of the most expensive resources in logistics.

3. What Should You Look for When Choosing a Pallet Exchanger?

Selecting the right pallet exchanger for your facility is not a one-size-fits-all decision. Several factors must be considered to ensure you get the best value for your investment. The first consideration is the type of pallet exchange required. Some systems are designed to handle specific pallet sizes and types, while others offer more versatility. It’s important to match the system’s capabilities with the specific requirements of your operation.

The durability of the system is another critical factor. Pallet exchangers are often exposed to heavy use, so investing in a robust machine made from high-quality materials is crucial for long-term performance. Look for systems with high load capacities and those that can withstand the rigors of your facility's operations.

Another consideration is the speed of operation. Automated pallet exchangers are generally faster than manual exchanges, but within this category, some systems are quicker than others. Depending on your throughput requirements, you might need a system that can operate faster without compromising the quality of the pallet exchange process.

4. How Do Pallet Exchanger Solutions Impact Operational Efficiency?

The impact of pallet exchanger solutions on operational efficiency can’t be overstated. By automating the pallet changeover process, facilities can achieve faster cycle times and reduce delays caused by manual pallet swapping. In many operations, time is money, and the ability to swap pallets seamlessly means fewer bottlenecks and smoother workflows.

Automation not only speeds up the process but also helps streamline the entire logistics chain. With automated pallet exchangers, it becomes easier to maintain just-in-time inventory practices and ensure that goods are always available when needed. This level of predictability is essential in industries where production lines are tightly scheduled and any delay can lead to significant losses.

By incorporating these systems, businesses also gain the advantage of real-time data tracking. Many modern pallet exchangers are integrated with Warehouse Management Systems (WMS) that allow managers to monitor pallet movements, performance metrics, and inventory levels. This data can be used to optimize the entire supply chain, identifying areas where additional improvements can be made.

Conclusion

In conclusion, the decision to incorporate pallet exchanger solutions into your operations is one that can have lasting, transformative effects on efficiency, safety, and sustainability. By automating the pallet exchange process, companies can reduce labor costs, increase productivity, minimize workplace injuries, and improve their environmental footprint. When selecting the right system, it’s important to consider factors such as durability, speed, and compatibility with existing infrastructure.

[claim]

Choosing a high-quality, reliable pallet exchanger is an investment in the future of your operations. As industries continue to evolve, having the right tools in place will be key to staying competitive and ensuring long-term success. By leveraging these systems, companies can not only improve their bottom line but also contribute to a safer, more sustainable work environment.